Maintaining heavy machinery is essential for its longevity and optimal performance. A well-organized reference for identifying and understanding each component plays a critical role in keeping the equipment running smoothly. This guide will help you navigate the various elements that make up your machine, providing you with clear visuals and descriptions to support your maintenance tasks.

Each mechanical element in your vehicle contributes to its overall efficiency. Knowing the layout and function of each section ensures that you can carry out repairs, replacements, or upgrades when necessary. With the right resources, even complex systems become much easier to understand and manage.

Accurate knowledge of the structure not only aids in troubleshooting but also improves your ability to maintain and repair the equipment without professional help. This knowledge is a valuable asset for both seasoned operators and those new to machine maintenance.

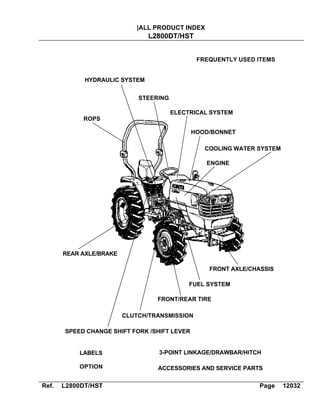

Understanding Tractor Components Layout

When dealing with complex machinery, having a clear visual reference for each individual component is crucial. The layout of these mechanical elements allows for easy identification, maintenance, and troubleshooting. A well-structured guide can significantly enhance your ability to efficiently service your equipment, ensuring it continues to operate at peak performance.

Key Mechanical Systems and Their Roles

Each section of your machine plays a specific role in its overall functionality. The engine, transmission, and hydraulic systems are just a few examples of vital components that require attention and understanding. Knowing where each element is located and how it interacts with others is essential for effective maintenance.

Interpreting the Layout for Efficient Maintenance

By familiarizing yourself with the arrangement of different systems and parts, you can perform repairs and replacements more quickly and accurately. This knowledge reduces downtime and prevents unnecessary damage to the machine. Proactive maintenance becomes far easier when you understand the layout of every component within the system.

Essential Components for Tractor Maintenance

To ensure that your equipment runs smoothly and efficiently, it is important to focus on key mechanical systems that are crucial for its operation. Understanding these vital components allows for proper upkeep, preventing breakdowns and costly repairs. Regular attention to these elements will extend the lifespan of your machinery and maintain its performance under various conditions.

The engine, hydraulic system, and transmission are just a few examples of essential areas that require ongoing maintenance. Each component plays a specific role, and failure in one part can significantly affect the overall functioning of the vehicle. By focusing on these systems, you can address issues before they escalate into larger problems, ensuring continuous productivity and reliability.

Regular checks of these critical systems help identify wear and tear, leaks, or other potential issues early on. Proper lubrication, cleaning, and timely replacements of worn-out components are key to keeping your equipment in optimal condition.

How to Use the Tractor System Layout

Understanding a machine’s system layout is essential for effective maintenance and troubleshooting. A well-organized visual guide helps operators and mechanics identify and locate specific components quickly. By familiarizing yourself with this reference, you can easily navigate through the complex systems and ensure that maintenance tasks are completed accurately.

Step-by-Step Interpretation

Start by locating the section relevant to the issue or component you need to work on. Once you have identified the system, examine its layout carefully. Each part is labeled for easy identification, making it simpler to understand the relationship between different components. Paying close attention to the details ensures you can quickly locate the required part for inspection, repair, or replacement.

Practical Applications for Maintenance

Using the system layout helps streamline your maintenance routine. When performing repairs or upgrades, refer to the diagram to confirm part numbers and placements. This reference reduces the likelihood of errors and ensures that all parts are correctly fitted back into their designated positions, leading to efficient and reliable repairs.