Maintaining machinery in top condition is essential for ensuring its long-term reliability and performance. Understanding how each part of your equipment functions and connects can make repairs easier and more efficient. Accurate identification of components plays a crucial role in troubleshooting issues and performing maintenance tasks.

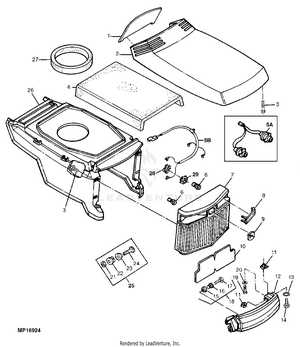

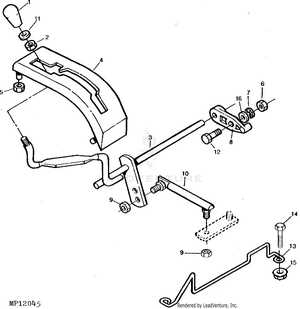

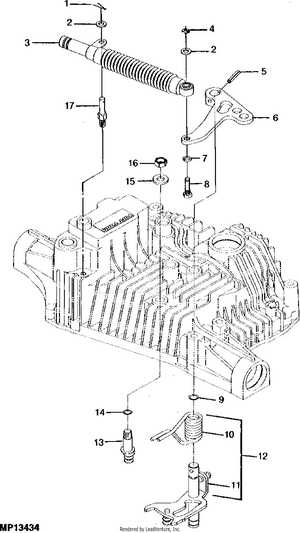

Having a clear visual representation of all the essential elements of your machine is an invaluable resource. It allows for quicker identification of malfunctioning or worn parts, helping to streamline the repair process. This guide aims to provide a comprehensive look at the critical parts and their functions, ensuring that your equipment operates smoothly for years to come.

Understanding Key Components

To maintain and repair any machinery effectively, it is essential to gain a clear understanding of its structure and how different components interact with each other. Each machine is composed of various elements that work together to ensure its proper functioning. Identifying these components and knowing their roles is vital for making informed decisions when it comes to repairs or upgrades.

Major Elements and Their Functions

Every machine consists of multiple systems and parts, each playing a specific role. Some components are responsible for propulsion, while others handle electrical systems or ensure fluid circulation. Understanding these major parts helps in diagnosing issues more accurately and performing necessary maintenance with precision. The proper functioning of each element ensures that the entire system operates smoothly and efficiently.

Importance of Accurate Identification

Accurate identification of machine elements is crucial for both troubleshooting and replacing worn-out components. Whether it’s a mechanical failure or a simple wear-and-tear issue, recognizing the exact part causing the problem is the first step in efficient repair. A visual guide can help users pinpoint the exact components, reducing the time spent searching for faults and increasing the likelihood of a successful fix.

Key Components of the Machinery

Understanding the primary systems and their respective elements is essential for maintaining and troubleshooting any vehicle or machine. Each part plays a distinct role in the overall performance, and recognizing them is critical for effective management. Below are the key components that ensure the smooth operation of the equipment.

Core Systems

- Engine System: Powers the machine and drives the mechanical operations.

- Transmission: Transmits power from the engine to the wheels or other functional parts.

- Electrical System: Controls the machine’s circuits, lights, and other electronic systems.

Essential Mechanical Parts

- Chassis: The framework that supports the other components and ensures structural integrity.

- Fuel System: Manages fuel delivery to the engine for proper combustion and efficiency.

- Hydraulic System: Transfers power to operate various mechanical parts through fluid pressure.

Each of these systems contributes to the overall efficiency and functionality, and understanding their roles can greatly assist in maintaining optimal performance over time.

How to Use the Component Guide Effectively

Utilizing a detailed visual guide can significantly simplify the process of identifying and replacing machinery elements. By following a structured approach, you can quickly locate malfunctioning components and determine which parts need attention. Knowing how to interpret and use such guides effectively can save time and ensure accurate repairs.

Begin by familiarizing yourself with the layout of the guide. Understanding how the components are organized, whether by system or functionality, helps to narrow down your search. Zooming in on specific sections and identifying labels can assist in pinpointing the exact part that requires replacement or maintenance. Make sure to compare the visual representation with the actual machine to confirm accuracy.

Once you have identified the necessary parts, gather the required tools and ensure you have the correct replacements. Having a step-by-step process in mind will help prevent mistakes and ensure a smoother repair or maintenance session.