When it comes to maintaining household equipment, knowing the layout of its internal components is essential. Having a clear understanding of how the machine is assembled can greatly simplify troubleshooting and repair processes. This knowledge allows for quick identification of any issues, making fixes more efficient and cost-effective.

Identifying individual sections of your appliance is the first step in understanding how it operates. Each section serves a specific function, and recognizing their roles is crucial for effective maintenance. Whether you’re replacing a malfunctioning part or simply conducting regular upkeep, knowing where each piece fits is key to a successful repair.

In this guide, we’ll explore the various sections, offering insights into their connections and the most common issues encountered with each. A well-organized overview of these components ensures that anyone, whether experienced or new to repairs, can navigate the assembly confidently.

Kenmore Dryer 110 Parts Overview

Understanding the internal structure of your appliance is essential for effective maintenance and repairs. Each unit consists of various sections that work together to achieve its primary function. Identifying and knowing the role of each component is crucial for diagnosing issues and ensuring smooth operation.

The motor and drum are at the heart of the system, responsible for driving movement and enabling drying. These essential elements are connected to other parts, such as belts and pulleys, which help to control the rotation of the drum. Regular inspection of these components can prevent common problems like jams or motor failure.

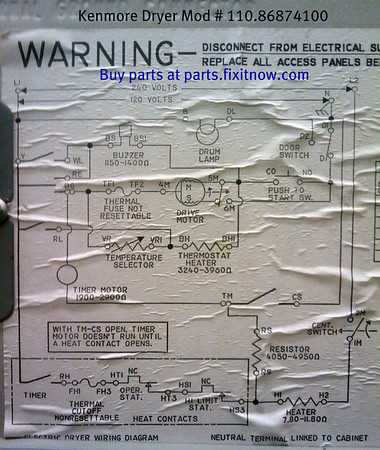

Heating elements are another important aspect to consider. They regulate temperature, ensuring that the machine reaches the necessary warmth to dry items effectively. Damaged or faulty heating elements can cause ineffective drying or overheating, leading to potential safety risks.

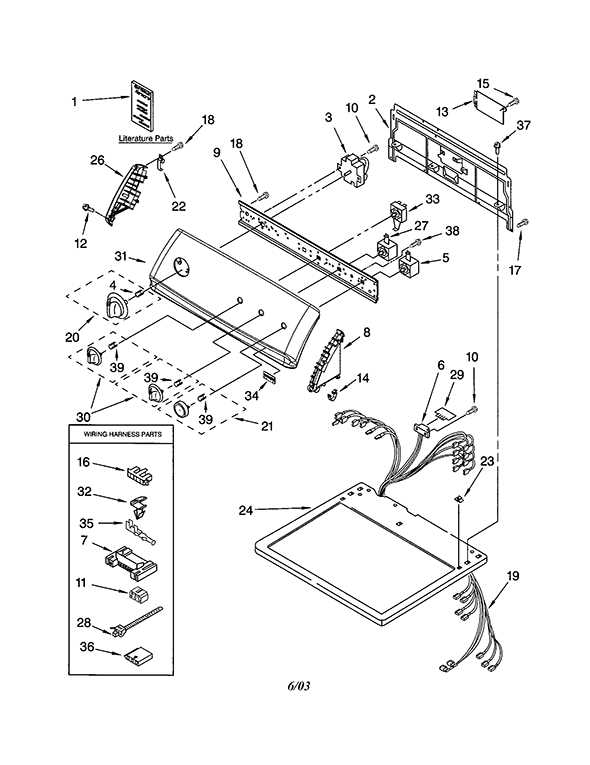

Other smaller components, such as sensors and control switches, help regulate the entire process. These parts are key for controlling settings and providing feedback to the user. A malfunction in these smaller sections may result in issues with the appliance’s functionality, making it important to keep them in good working order.

Identifying Key Components of the Dryer

To properly maintain and repair any home appliance, it’s crucial to identify its key internal components. These elements work together to ensure the machine functions efficiently, and recognizing each one helps in diagnosing issues when they arise. Understanding the role of each section allows for more precise repairs and long-term durability.

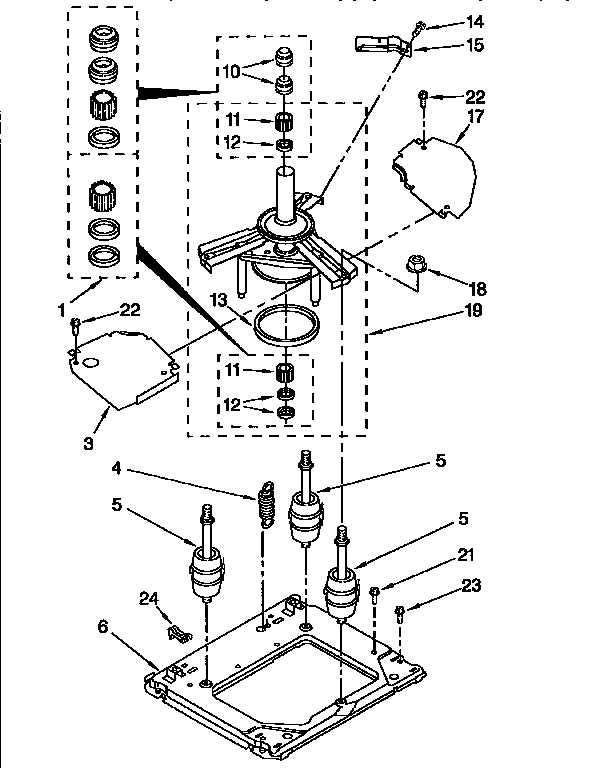

Motor and Drum Assembly

The motor is a central part of the unit’s operation. It powers the movement of the drum, which holds and rotates the clothes. A malfunctioning motor can lead to problems like failure to start or unusual noises. The drum, which is typically made of metal or durable plastic, rotates to tumble clothes and facilitate the drying process. Checking for wear and tear in both components can prevent common mechanical issues.

Heating Mechanism

The heating element is essential for raising the temperature inside the unit, allowing for effective drying. If the heating element malfunctions, the appliance will fail to generate enough heat, leading to wet clothes even after a full cycle. Inspecting the heating system regularly ensures that it operates safely and efficiently. Over time, wear on heating coils can cause electrical failures or even safety hazards.

Step-by-Step Guide to Assembly

Reassembling your appliance after maintenance or repairs requires careful attention to each component. Following a structured process ensures that all sections are correctly positioned and connected, restoring the unit to full functionality. This guide will walk you through each step, from the motor assembly to the final adjustments.

Start with the Motor and Drum

Begin by installing the motor securely in its designated housing. The motor is responsible for powering the rotation of the drum. Once the motor is in place, attach the drum carefully, making sure it spins freely and aligns with the necessary pulleys and belts. Proper alignment is crucial to avoid unnecessary wear and tear.

Attach the Heating Element and Electrical Components

The next step involves positioning the heating element within its compartment. Ensure that the connections are secure and that there are no exposed wires, which could lead to safety hazards. Once the heating element is properly installed, connect the electrical components and verify that all connections are tight and in place. This will allow the machine to reach optimal performance during operation.