When maintaining or repairing your chainsaw, having a clear understanding of its internal structure is crucial. A detailed visual reference can help identify each individual piece and ensure correct assembly or replacement. With the right knowledge, even complex maintenance tasks become more manageable.

Whether you’re a seasoned professional or a beginner, knowing the parts of your equipment inside and out can significantly improve the efficiency of your work. Accurate identification of every component allows for quicker repairs and enhances the overall longevity of your tool.

In this article, we’ll walk you through a comprehensive breakdown of your chainsaw’s key elements, offering you a practical guide to fixing or upgrading your machine. Equipped with this knowledge, you can make informed decisions and carry out necessary actions with confidence.

Understanding the Husqvarna 51 Diagram

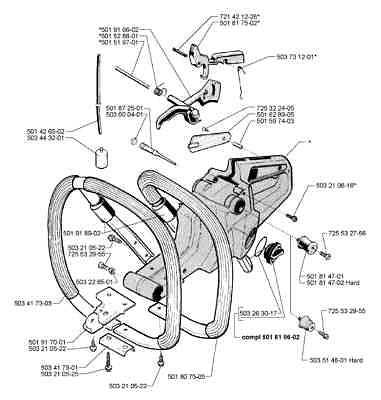

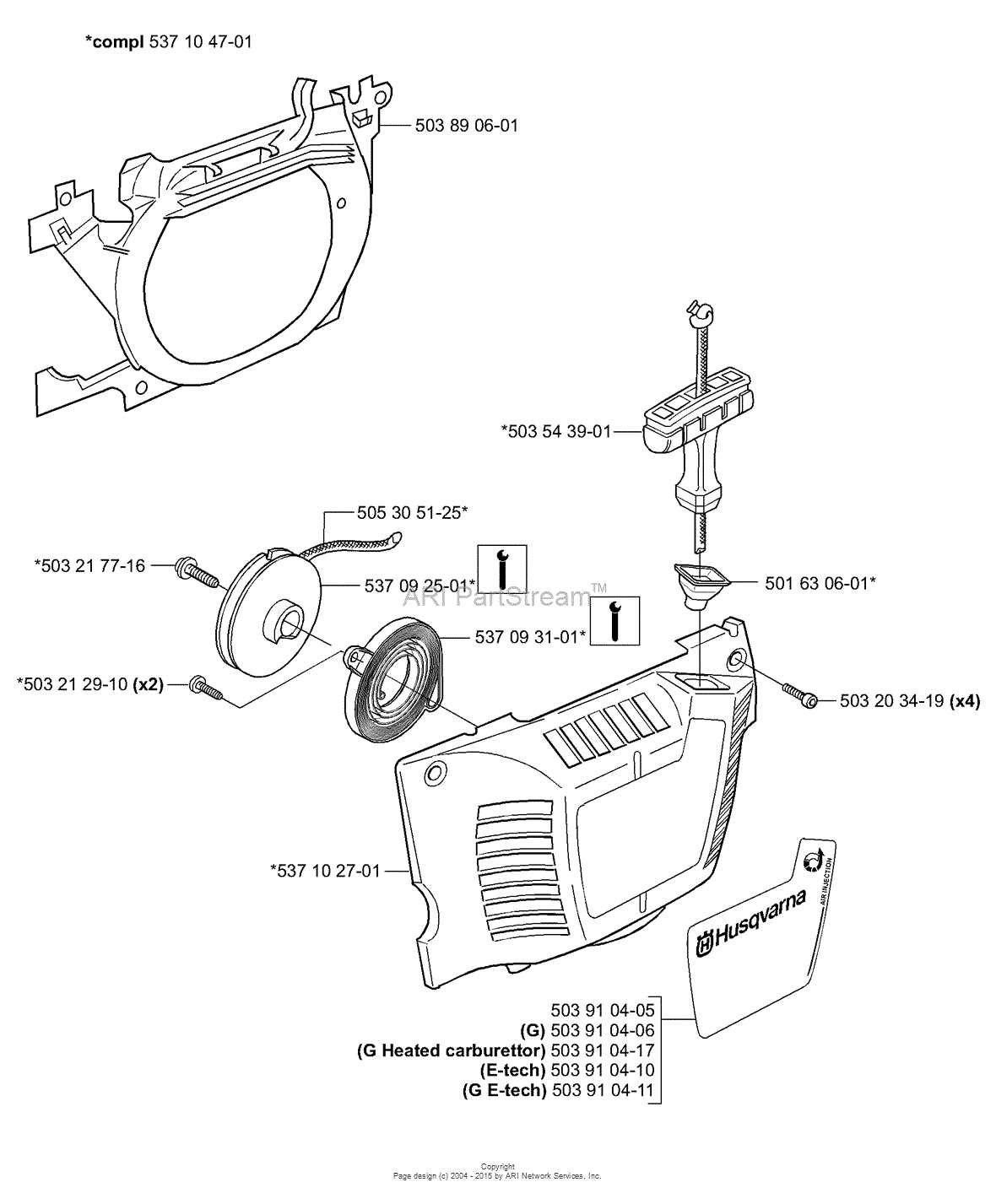

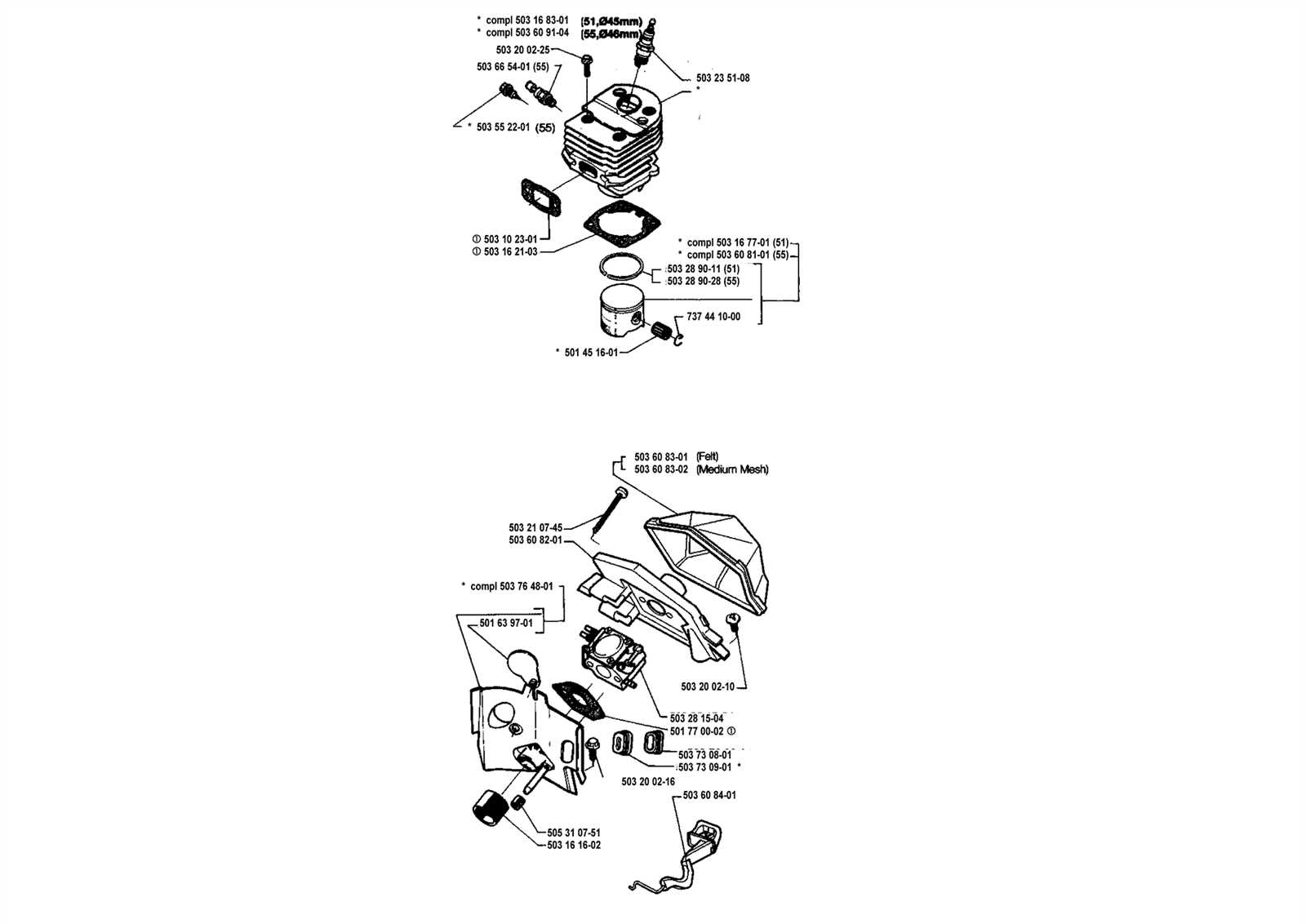

To effectively maintain and repair your chainsaw, it’s essential to have a clear visual guide of its structure. A detailed illustration can help you navigate the various components and understand how each part interacts within the machine. This knowledge is key to identifying any issues and ensuring that everything is in working order.

Each element of your chainsaw has a specific function, and being able to distinguish between them is crucial. Whether you are troubleshooting or simply performing routine maintenance, having an organized reference can save time and effort. A well-detailed chart allows you to identify components quickly, ensuring you don’t miss anything important.

By understanding the layout and positioning of the different parts, you can more easily determine what needs attention. This will also help you avoid mistakes that could occur when assembling or disassembling your equipment. With this visual guide, you will gain the confidence to work on your chainsaw without uncertainty.

Identifying Key Components in the Diagram

Recognizing the essential elements of your chainsaw is crucial for successful maintenance and repair. Each component serves a specific role in ensuring that the machine operates smoothly. Understanding the main parts will help you pinpoint potential issues and carry out necessary replacements or repairs with ease.

The engine, bar, chain, and fuel system are among the most critical sections of your tool. Identifying the proper positioning and function of these elements will make it easier to spot faults and perform effective troubleshooting. By referring to a detailed guide, you can accurately distinguish between parts that need attention and those that are functioning correctly.

Additionally, knowing how these components interact with each other allows for a better understanding of how your chainsaw operates as a whole. This knowledge is key to maintaining the efficiency and longevity of your equipment, preventing unnecessary repairs and ensuring peak performance at all times.

How to Use the Parts Diagram for Repairs

Utilizing a detailed reference guide can greatly simplify the process of fixing or replacing components in your chainsaw. By examining a clear visual layout, you can identify the exact parts that need attention, which streamlines the repair process and ensures you don’t miss any critical elements.

Start by locating the malfunctioning area and matching it to the corresponding section on the illustration. This will give you a clear understanding of which parts are connected and how they interact. Once you have identified the faulty components, you can proceed with disassembly and replacement more efficiently, minimizing the risk of error.

When performing repairs, always ensure that you follow the correct assembly order and use the right tools for the job. A detailed guide can also highlight common issues, allowing you to troubleshoot effectively and avoid unnecessary disassembly. This approach ensures that repairs are done accurately and safely, keeping your equipment in top working condition.