In the world of industrial machinery, knowing the layout and structure of key components is crucial for ensuring smooth operation and efficient maintenance. Understanding how individual parts interact with one another can significantly improve the performance and longevity of the machine. Proper knowledge allows for easier identification of wear and tear, preventing costly downtime and repairs.

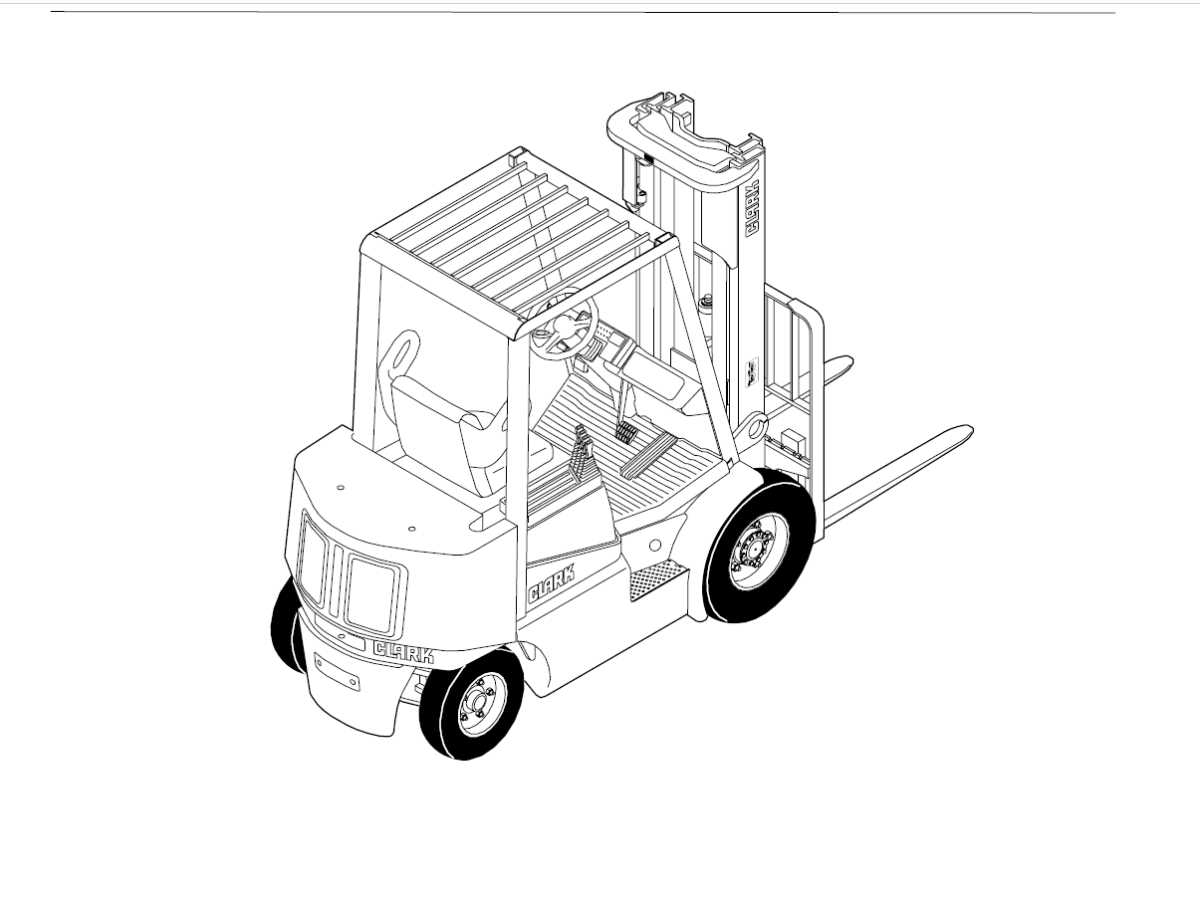

Visual representations play a vital role in grasping how all the elements come together. They provide a clear understanding of each component’s position and function, offering a valuable reference for technicians and operators alike. With such a guide, troubleshooting becomes simpler and more accurate, leading to quicker solutions and fewer mistakes.

When it comes to regular servicing and repairs, being able to identify the right components is essential. Having access to a detailed visual guide helps ensure that each element is properly maintained or replaced, extending the life of the equipment and minimizing disruption in operations.

Understanding Equipment Component Layout

Proper knowledge of the layout and configuration of machine components is essential for efficient maintenance and troubleshooting. When operators and technicians understand how parts are organized, it allows them to more easily identify problems, carry out repairs, and optimize performance. A clear grasp of each component’s role within the system contributes to smoother operations and longer equipment lifespan.

Key Elements of Equipment Configuration

Machines often have a specific arrangement of core elements that support overall functionality. These components can include critical systems such as the engine, hydraulics, electrical wiring, and chassis. A detailed understanding of their positions and relationships ensures that any potential issues can be quickly located and addressed. Identifying where each piece fits within the larger system is vital for maintaining smooth workflows and minimizing downtime.

The Importance of Accurate Identification

Accurate identification of every element within the equipment’s structure is crucial for both preventative maintenance and timely repairs. Having a well-structured guide to the machine’s internal components allows workers to quickly spot wear or damage, improving the response time to necessary interventions. This knowledge helps ensure that the equipment runs efficiently, with minimal interruptions or costly repairs.

How to Use Equipment Component Visual Guide

Using a visual guide for machine components can greatly enhance the efficiency of maintenance and repair tasks. Such resources help workers quickly locate specific elements and understand their function within the larger system. With the right knowledge, technicians can streamline troubleshooting, making the entire process faster and more accurate. This guide serves as a valuable tool, providing clear references for identifying each part, its placement, and its role in the overall operation.

Locating Specific Elements

One of the main advantages of using a visual guide is the ability to pinpoint components with ease. By following the layout provided, users can directly reference the corresponding parts within the machinery, making the identification process far more intuitive. Clear labeling and organized schematics ensure that even complex systems are understandable, reducing the risk of errors and minimizing time spent on locating specific elements.

Ensuring Proper Maintenance and Repairs

When performing maintenance or repairs, it is essential to understand how each element fits into the system and how they work together. The visual guide can be a valuable resource to ensure that components are replaced or serviced correctly. By following the illustrated instructions, users can reduce the chance of misdiagnosis or improper handling, ultimately leading to a longer service life and fewer issues down the line.

Essential Equipment Components for Maintenance

To ensure smooth operation and minimize downtime, regular maintenance of key machine components is essential. A proactive approach to servicing critical elements can help extend the life of the equipment and prevent costly repairs. By focusing on the most vital systems, operators and technicians can prioritize their efforts, addressing issues before they become serious problems. Understanding which components need attention most often is crucial for keeping everything running efficiently.

Key Systems to Focus On

The heart of any machine is its engine and powertrain, which require regular checks for optimal performance. The hydraulic system, electrical connections, and steering components also demand frequent attention. These systems are responsible for most of the machine’s functionality and can cause significant disruptions if neglected. Regular inspection and replacement of worn-out components, such as belts, seals, and filters, help maintain the overall integrity of the equipment.

Preventative Measures for Longevity

Preventative maintenance goes beyond just fixing issues. By regularly inspecting and servicing essential components, operators can catch small problems before they escalate. For example, maintaining the cooling system and checking fluid levels can help avoid overheating, while examining tire wear and alignment ensures safe operation. Timely replacement of consumables, such as oil and air filters, is another crucial aspect of maintaining the equipment’s health and efficiency.