Maintaining heavy machinery in top condition is crucial for ensuring smooth performance and preventing costly downtime. Understanding the layout and components of your equipment is the first step toward efficient maintenance. Properly identifying and addressing potential issues helps prolong the life of the machine and enhances its reliability.

In this guide, we will delve into the key aspects of machine repair, focusing on a detailed breakdown of the essential elements. Whether you’re a professional technician or a machine owner, having a clear understanding of the internal workings of the equipment can make a significant difference in troubleshooting and repairs.

Being proactive in identifying worn or damaged components ensures quicker fixes and avoids unexpected breakdowns. Through careful examination, you’ll gain insight into the most common issues and solutions for maintaining high performance over time.

Rayco 1625 Super Jr Overview

When it comes to compact equipment designed for effective land clearing and tree stump removal, understanding the features and capabilities of the machine is essential. This type of equipment is engineered for durability and ease of use, allowing operators to efficiently tackle tough outdoor tasks. Knowing how the machine operates, along with its primary components, is key to ensuring proper maintenance and troubleshooting.

Key Features and Performance

Built with high-performance features, this machine stands out for its ability to access tight spaces and maneuver through challenging terrains. It offers a combination of power, speed, and compact size, making it ideal for both residential and commercial projects. Understanding its design and functionality can help operators optimize its potential and achieve the best results in a variety of conditions.

Maintenance and Longevity

Regular upkeep and timely repairs are crucial for maintaining the efficiency of the equipment over time. Ensuring that each component is in optimal condition helps reduce downtime and prevents unnecessary wear and tear. Having a solid understanding of the machine’s internal structure makes it easier to identify potential issues before they lead to major repairs, ensuring long-term functionality.

Understanding the Parts Layout

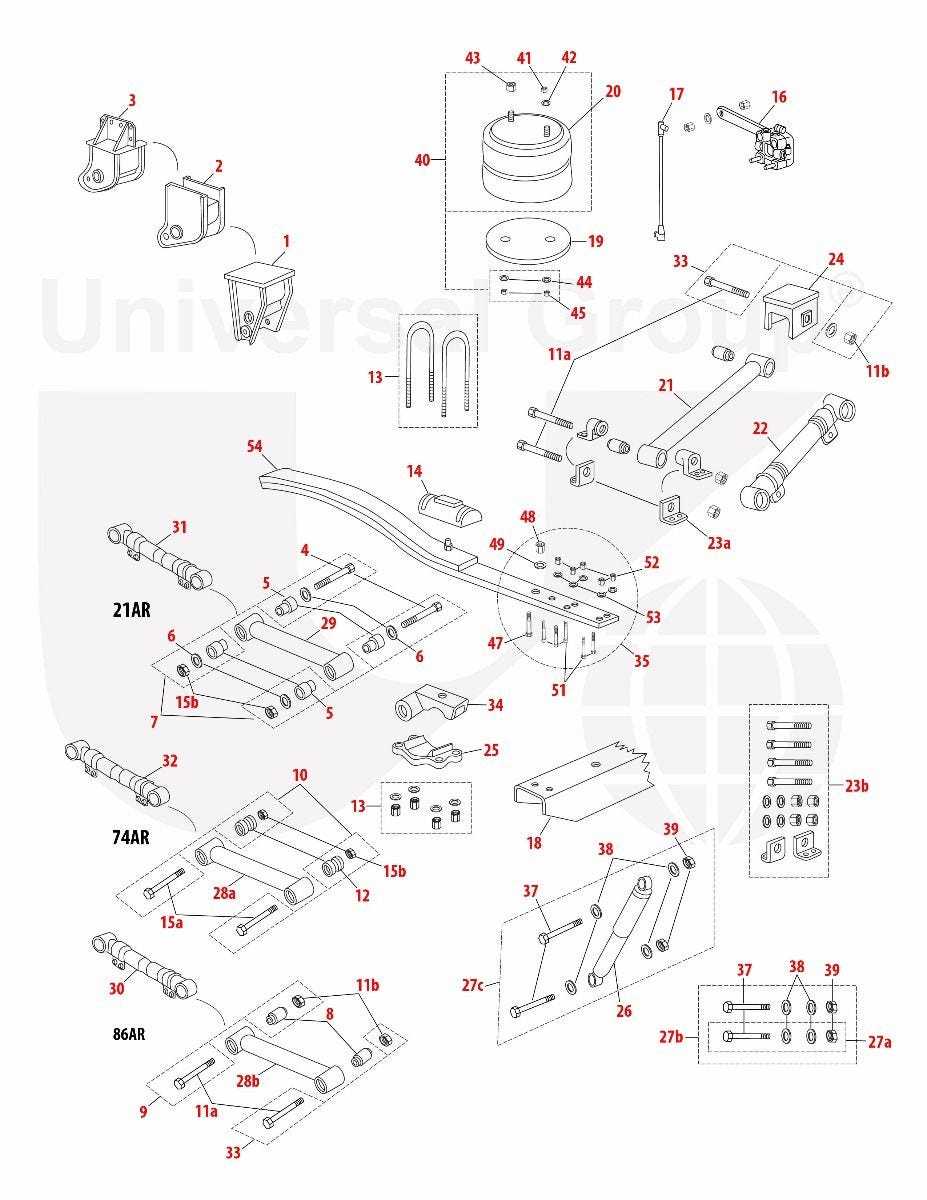

Having a clear understanding of the internal layout of a machine is vital for proper operation and efficient troubleshooting. Every component plays a critical role in the overall functionality, and knowing where each part is located helps operators quickly address any issues that arise. A comprehensive overview of the machine’s configuration makes maintenance more intuitive and reduces the likelihood of errors during repairs.

Component Identification and Function

The main elements of the machine are designed to work in unison, with each part serving a specific purpose. By familiarizing yourself with the key components, such as the engine, hydraulic system, and drive mechanisms, you can ensure smooth operation and quicker identification of malfunctioning parts. Knowing how each piece fits into the overall design helps prevent costly mistakes during service.

Layout for Maintenance Efficiency

Effective maintenance begins with understanding the layout of the machine. When you know the precise location of essential components, you can perform routine checks with ease and efficiency. This also allows for faster diagnostics when issues occur, reducing downtime and preventing more extensive damage from neglecting smaller problems. The layout of the equipment is designed for accessibility, ensuring that repairs can be made swiftly and accurately.

Essential Maintenance and Repair Tips

Proper upkeep and timely repairs are essential for maximizing the lifespan and performance of any heavy-duty equipment. Regular maintenance ensures that all systems remain in optimal condition, preventing breakdowns and minimizing costly downtime. Staying proactive with inspections and addressing minor issues before they escalate can lead to smoother operations and reduce the need for extensive repairs.

Routine Inspections and Cleaning

One of the most important maintenance tasks is conducting regular inspections. Check critical components such as the engine, hydraulic system, and drive components for any signs of wear or damage. Cleaning these parts regularly helps prevent buildup that could impair performance. Ensure filters and air intakes are free from debris to keep the system running efficiently.

Addressing Wear and Tear

Over time, even the most durable machinery will experience some degree of wear. Identifying these areas early allows you to make minor repairs before they become more serious. Pay special attention to moving parts and seals, which are often the first to show signs of stress. Replacing worn-out components as soon as possible can extend the machine’s working life and avoid further complications.