When working with small power units, it is crucial to have a clear understanding of the key elements that ensure their proper functionality. Whether you are repairing, maintaining, or upgrading these machines, identifying each component plays a significant role in achieving optimal performance.

Knowing the layout and specific functions of the internal parts allows for more efficient troubleshooting and enhances the accuracy of maintenance efforts. This guide will help you explore the different sections of these units and explain how they interact with each other to provide smooth operation.

By mastering the structure and organization of the individual components, you will be better equipped to handle repairs and keep the system running smoothly for longer periods. This knowledge can save time, money, and effort when dealing with common issues that arise over time.

Understanding Key Components of Small Power Machines

Small power units are complex systems composed of various elements that work together to provide reliable performance. Each section has a specific role, and understanding these roles is crucial for proper maintenance and repair. By focusing on the main functional areas, you can ensure that the equipment operates smoothly and efficiently over time.

Critical Internal Mechanisms

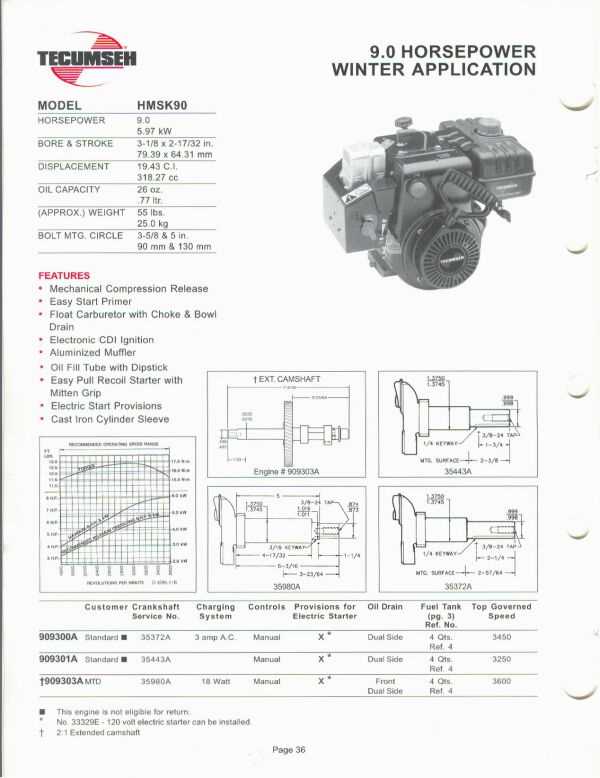

The internal structure consists of multiple interconnected systems, including the combustion process, fuel delivery, and ignition. Each mechanism plays a vital role in the operation of the entire system. Recognizing the function of each individual element allows for easier identification of potential problems and streamlines the troubleshooting process.

External Elements and Connectivity

In addition to the internal workings, external components such as cooling systems, exhaust paths, and connection points are just as important. These parts ensure that the internal processes remain efficient by preventing overheating, managing exhaust flow, and maintaining proper connectivity with other devices. Regular inspection of these external elements is crucial to avoid common issues that might arise during prolonged use.

Importance of Proper Part Identification

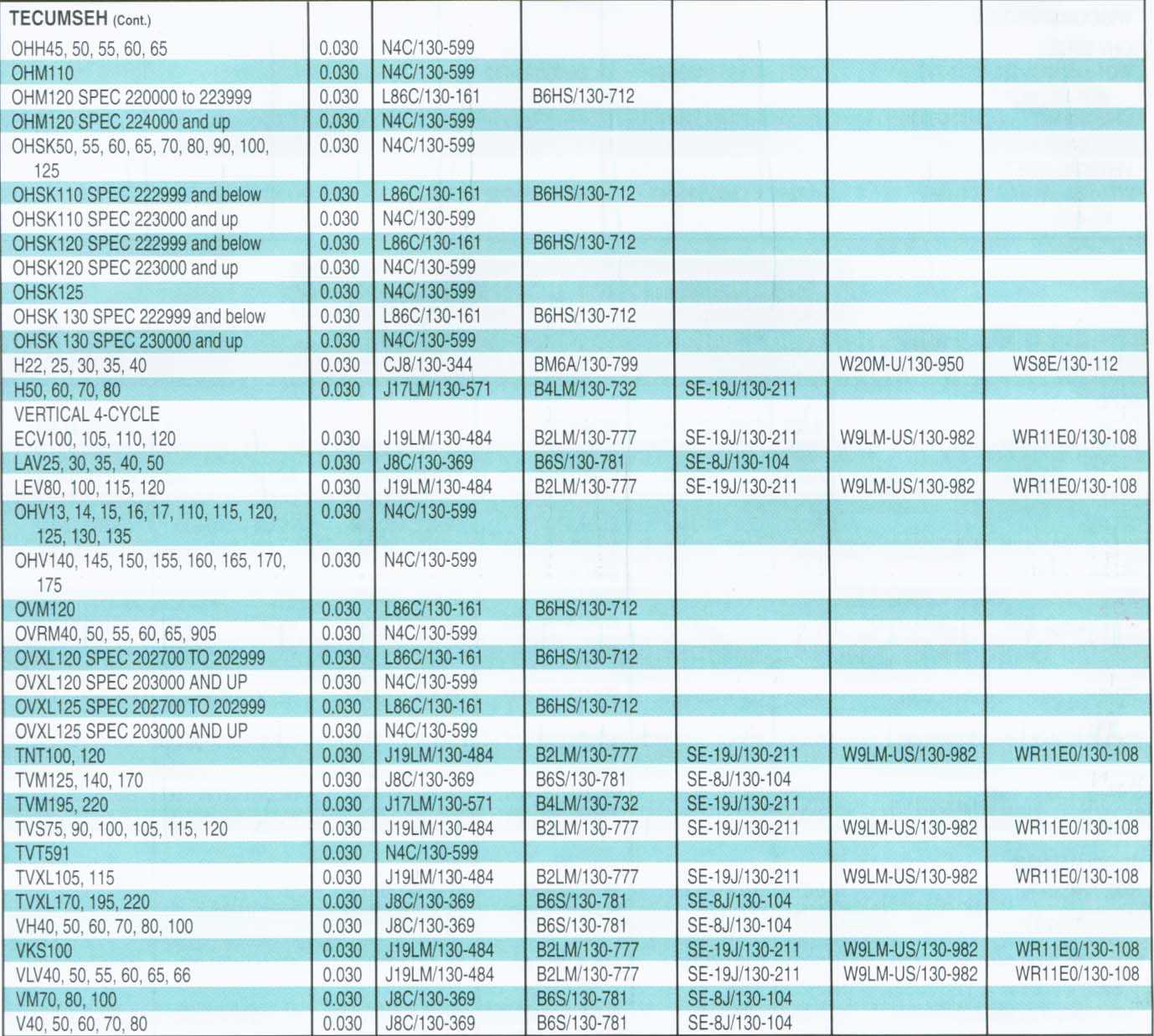

Identifying the correct components in any mechanical system is crucial for ensuring its longevity and efficiency. Misidentification can lead to improper repairs, unnecessary replacements, and potentially greater issues down the line. Being able to recognize and understand each individual element helps streamline maintenance procedures and prevent costly mistakes.

Improved Repair Accuracy

When each component is accurately identified, repairs can be performed with greater precision. Knowing exactly what needs to be addressed reduces the likelihood of overlooking a critical issue or mistakenly replacing the wrong part. This not only saves time but also helps in restoring full functionality quickly.

Enhanced Troubleshooting Efficiency

Proper identification of all parts facilitates faster and more effective troubleshooting. When the components are understood in their entirety, it becomes easier to pinpoint specific faults and determine the most suitable course of action. This process allows for quicker resolutions and minimizes downtime.

Step-by-Step Guide to Machine Maintenance

Regular upkeep is essential for maximizing the performance and lifespan of mechanical systems. A well-maintained unit operates more efficiently, consumes less fuel, and has fewer chances of unexpected breakdowns. Following a clear, methodical approach to maintenance ensures that every component is properly serviced, preventing common issues from becoming major problems.

Routine Checks and Lubrication

Start by performing regular inspections of all moving parts. Check for signs of wear, leaks, or blockages. Ensure that lubricants are applied where needed to reduce friction and extend the life of components. Proper lubrication helps in preventing overheating and unnecessary strain on the system, ensuring smooth operation.

Cleaning and Component Inspection

Cleaning the system regularly is crucial for maintaining efficiency. Dirt, dust, and debris can accumulate over time and interfere with the proper functioning of key elements. Remove any buildup and inspect all components for damage or deterioration. Replacing worn or damaged parts early on can prevent more severe failures in the future.