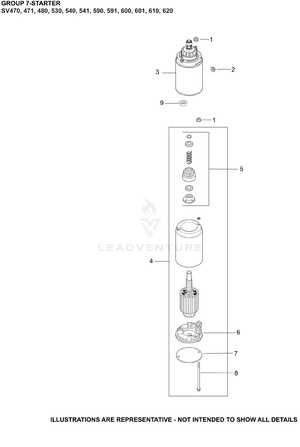

Every engine system relies on a precise arrangement of internal elements to function smoothly. Whether you’re performing routine maintenance or addressing a malfunction, having a clear understanding of how each piece fits together is essential for successful repairs. An accurate visual reference can significantly ease the process of identification and replacement.

Detailed illustrations provide a comprehensive overview, allowing technicians and enthusiasts alike to navigate through the complex network of mechanical components. Knowing the exact positioning of each unit ensures better diagnostics and reduces errors when replacing worn-out or damaged parts.

By studying these layouts, you gain a valuable tool to assist in recognizing issues quickly, saving both time and resources. Familiarity with these diagrams can lead to more efficient engine management and longer-lasting performance of your equipment.

Understanding Engine Starting System Components

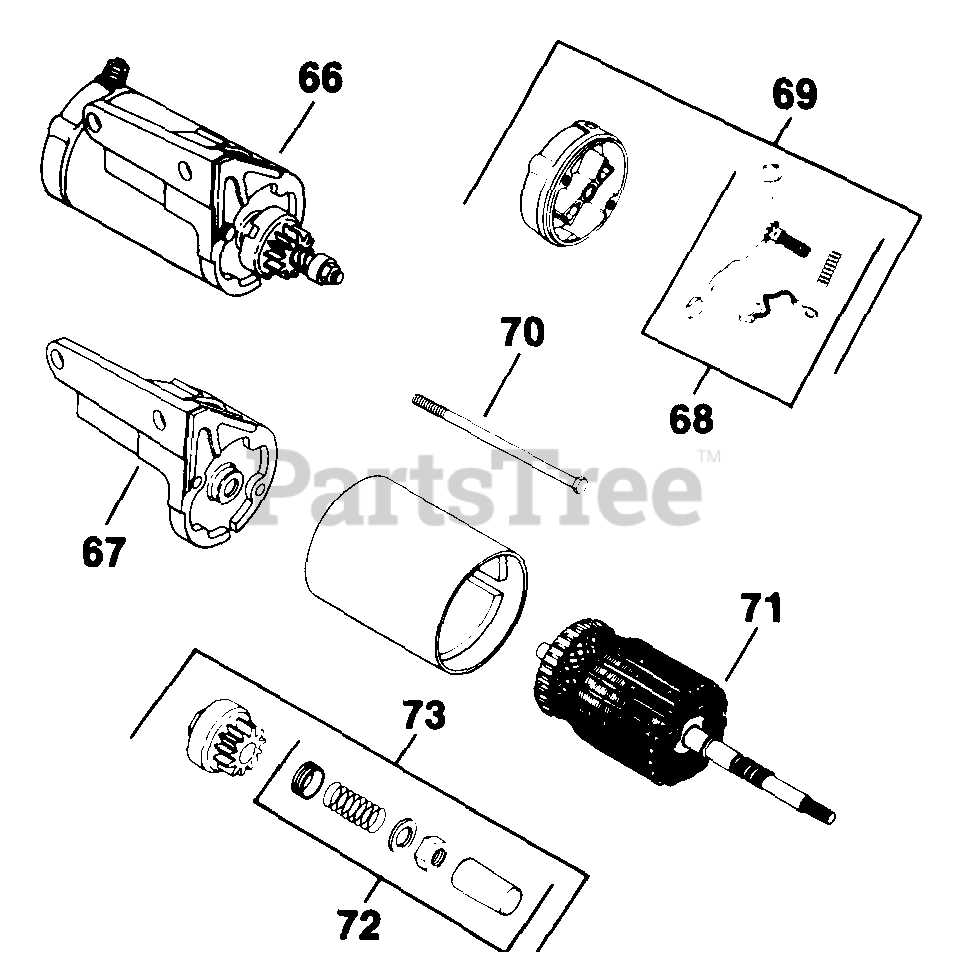

The efficient operation of any engine relies heavily on a well-coordinated system of components that work in harmony to initiate power. Understanding the core elements involved in starting the engine is crucial for identifying malfunctions and performing precise repairs. Each component plays a specific role in converting energy into mechanical movement to get the engine running.

Key Components in the Starting System

The most essential elements include the motor, solenoid, and drive mechanism, all of which are responsible for initiating the engine’s rotational motion. The motor delivers power to rotate the flywheel, while the solenoid engages the motor with the engine. Meanwhile, the drive mechanism ensures proper engagement and disengagement as the engine starts up and runs.

Identifying and Replacing Components

Accurate identification of each component is vital for effective repairs. If any part malfunctions, it can prevent the engine from starting, or lead to further damage. Replacing worn or faulty parts with high-quality replacements ensures that the system continues to function reliably, maintaining the engine’s overall performance and longevity.

How to Read Engine Component Layout

Understanding a system’s layout is a key step in troubleshooting or replacing parts. These visual aids provide a simplified representation of the internal structure, making it easier to see how different elements interact with one another. When reading through such diagrams, focus on identifying the connections and the flow of energy that each part facilitates.

Each symbol or image represents a specific part of the mechanism, with lines and arrows showing how they are interconnected. It’s important to follow the paths of the energy flow or movement to determine which components need attention. Familiarizing yourself with the common symbols used can greatly speed up the identification process and make repairs more efficient.

Replacing Engine Components Effectively

Replacing malfunctioning or worn-out elements within an engine is crucial for maintaining its performance and ensuring reliable operation. Proper replacement not only restores functionality but also prevents further damage to other connected components. To replace a part effectively, it is essential to follow the correct steps and use high-quality replacements to maintain the system’s integrity.

First, identify the faulty component by carefully examining the layout and assessing the system’s overall performance. Once identified, ensure that the replacement component matches the specifications required for optimal function. Precision is key when fitting new parts to ensure proper engagement with the rest of the system.

After installing the new part, check all connections and test the system to ensure everything operates smoothly. Regular maintenance and timely replacements will extend the life of the engine and reduce the frequency of future repairs.