Maintaining the functionality of your vehicle’s braking system is crucial for safe operation. Understanding the various elements that make up this system can help you diagnose issues and perform effective repairs. This guide will provide a detailed overview of the key components involved, ensuring that you’re well-equipped for any maintenance or replacement tasks.

Proper knowledge of your vehicle’s braking mechanism allows you to address common problems, replace damaged items, and improve overall performance. Whether you’re a professional mechanic or a car enthusiast, familiarizing yourself with the components involved is an important step in ensuring the safety and reliability of your vehicle.

By exploring each crucial element of the braking system, you’ll gain insight into their roles and how they interact. This information is valuable for making informed decisions during repairs and ensuring that every part functions as intended.

Understanding Vehicle Stopping Mechanism

Every vehicle relies on a complex system to halt safely and efficiently. These systems are made up of multiple components working together to provide the necessary force to stop the vehicle when required. A thorough understanding of how these parts interact is essential for ensuring proper functionality and longevity.

Key Elements of the Stopping System

The stopping mechanism consists of various critical components, including the actuator, friction materials, and hydraulic systems. Each element has a specific role, from generating the force required to halt the motion to dissipating energy through heat. Proper maintenance and timely replacement of any worn or damaged component are key to ensuring the system’s effectiveness.

How Components Interact for Safety

These individual parts work in unison to allow the driver to control the vehicle. The actuator initiates the process by transferring pressure, while friction materials slow down the movement. The hydraulic systems help control the fluid flow, which further ensures that each part responds as expected. Understanding the way these elements collaborate enhances overall safety and ensures that all parts are functioning at their optimal level.

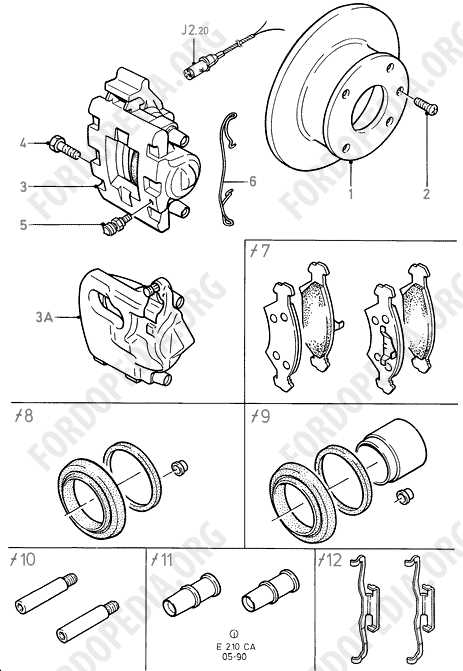

Identifying Key Components in Stopping System Layout

A comprehensive layout of the stopping system helps in visualizing how different elements work together to ensure safe vehicle operation. By examining this layout, it’s possible to identify each individual part’s role and understand how they contribute to the overall functionality. Knowing the names and locations of these components can significantly aid in maintenance and repair tasks.

Important Elements in the System

The layout reveals a range of components, each with a specific function. These include the friction surfaces, hydraulic pistons, and fluid reservoirs, among others. Each part is carefully designed to perform a particular task, whether it’s generating stopping power, controlling fluid flow, or providing the mechanical force necessary for halting the vehicle.

How to Identify and Assess Components

When assessing the layout, it’s important to familiarize yourself with the typical configuration and placement of each component. This knowledge allows for easier identification of any worn or malfunctioning parts. Visualizing how each part is connected and functions within the system enables a more accurate diagnosis and more effective repairs, ensuring everything operates smoothly.

Steps to Replace Vehicle Stopping System Components

Replacing worn or damaged components in a vehicle’s stopping mechanism is a critical maintenance task to ensure safety and reliability. Following the correct steps is essential for effective replacement and avoiding further issues. This section will guide you through the process of replacing key elements involved in the system.

Preparation and Safety Measures

Before starting the replacement process, it’s important to ensure that you have all the necessary tools and replacement components. Disconnect the vehicle’s power source, engage the parking brake, and use jack stands to securely lift the vehicle. Wear protective gloves and eye protection to minimize the risk of injury during the process.

Replacement Process

Begin by carefully removing the components that need replacing. This may involve disconnecting hydraulic lines, unscrewing bolts, or removing protective covers. Once the old parts are removed, install the new ones by following the reverse order, ensuring each component is properly aligned and secured. After the installation is complete, test the system to ensure everything functions correctly before lowering the vehicle.