Maintaining and repairing outdoor machinery requires a clear understanding of its individual components. Proper knowledge helps to ensure efficient performance and longevity of the equipment. Without a detailed view of each part, it can be difficult to identify problems and address them effectively.

In this guide, we will explore the various essential components that make up your lawn care machine. We’ll provide a detailed breakdown of their functions, helping you recognize the most common areas that require attention and care. This understanding allows you to troubleshoot, repair, and maintain your machine with confidence.

Whether you’re a novice or an experienced user, having a reference to visualize the parts can be immensely helpful. With the right information, you can enhance the durability and performance of your equipment over time. Knowing the intricate details will ultimately save time and money in the long run.

Understanding Lawn Care Equipment Components

To keep your outdoor machine running smoothly, it’s important to understand its core elements and how they work together. Each piece plays a vital role in the overall performance, ensuring that everything functions as intended. Whether you’re using the machine regularly or for occasional tasks, recognizing the key components can make maintenance and repairs much easier.

Main Components of the Equipment

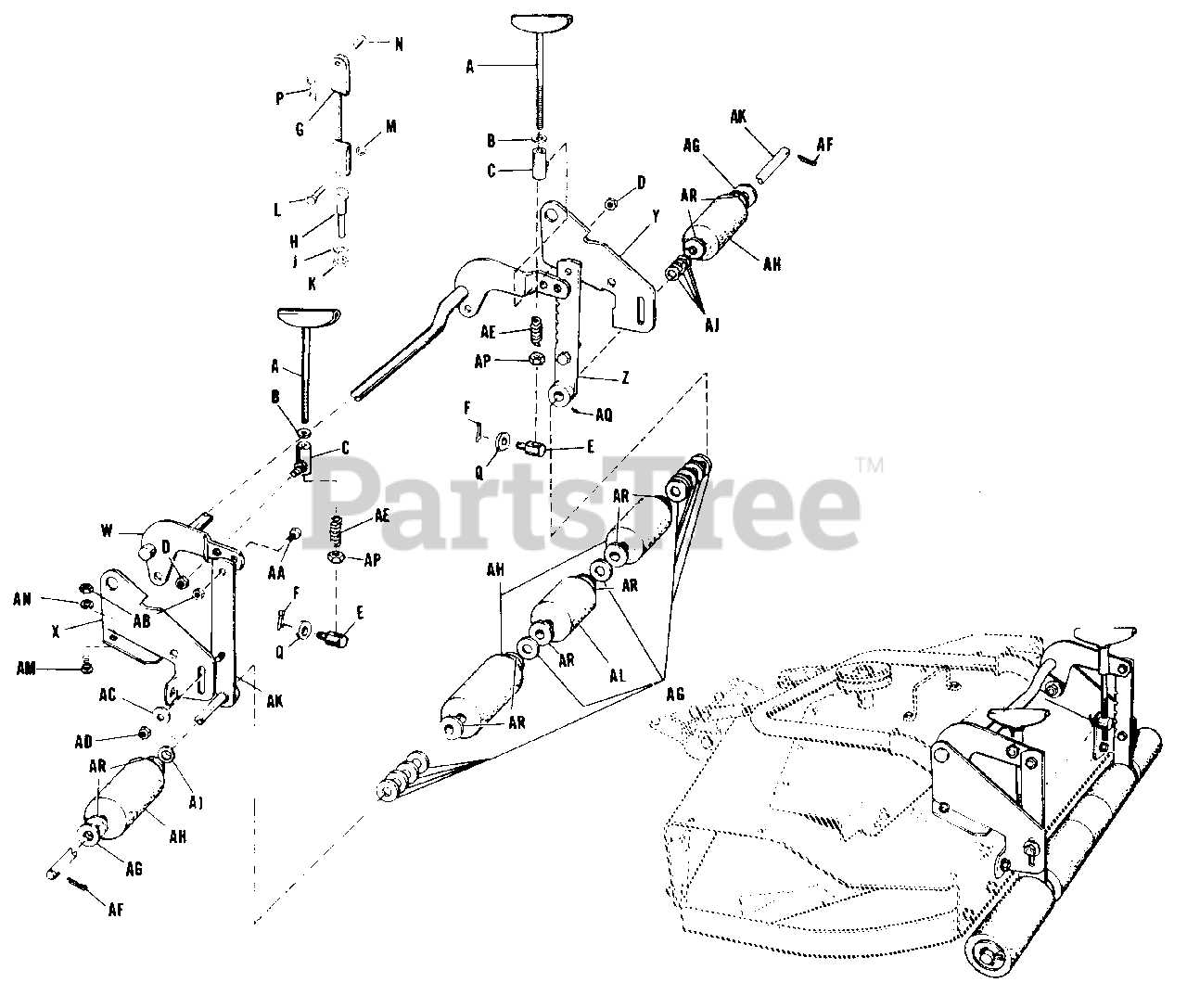

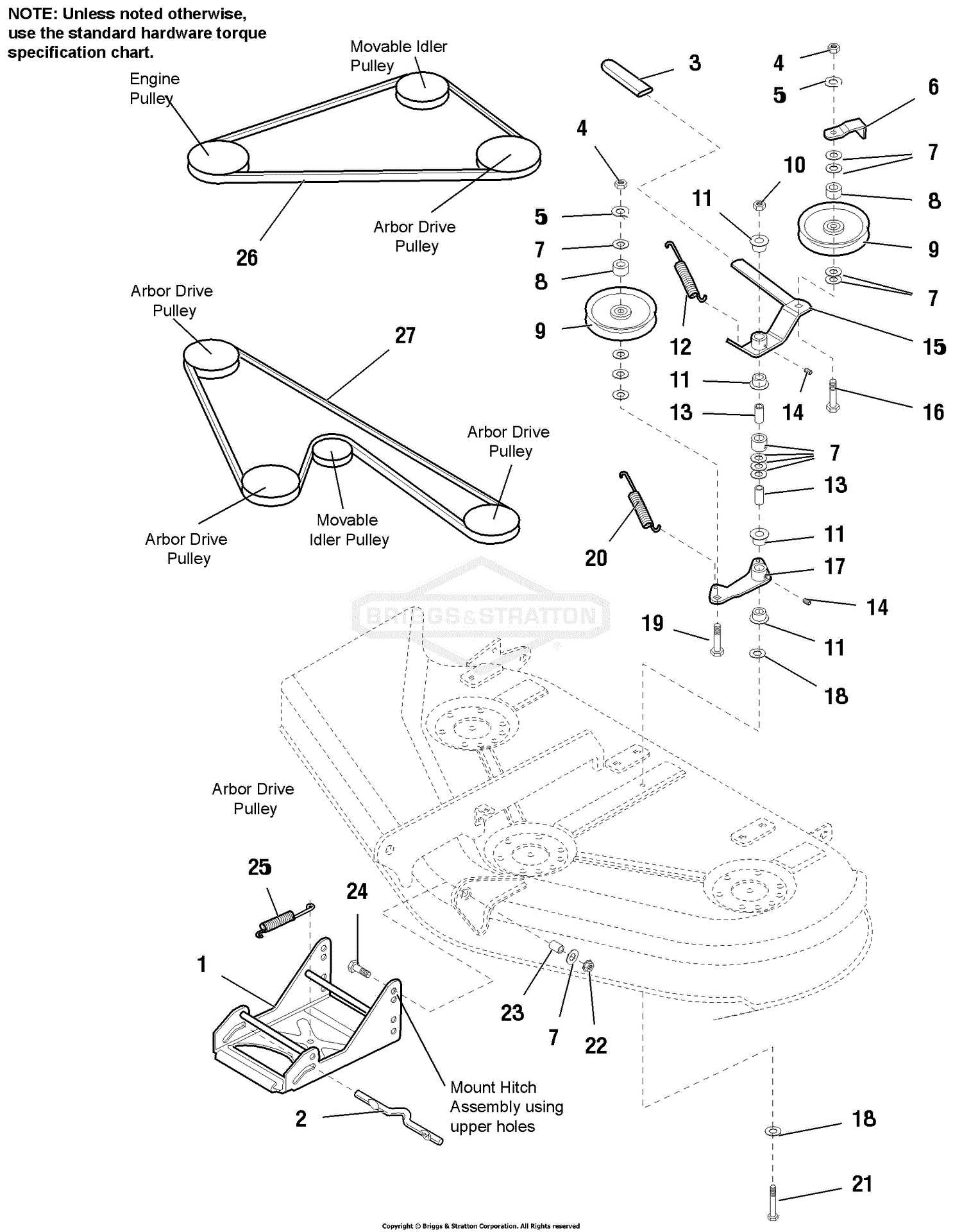

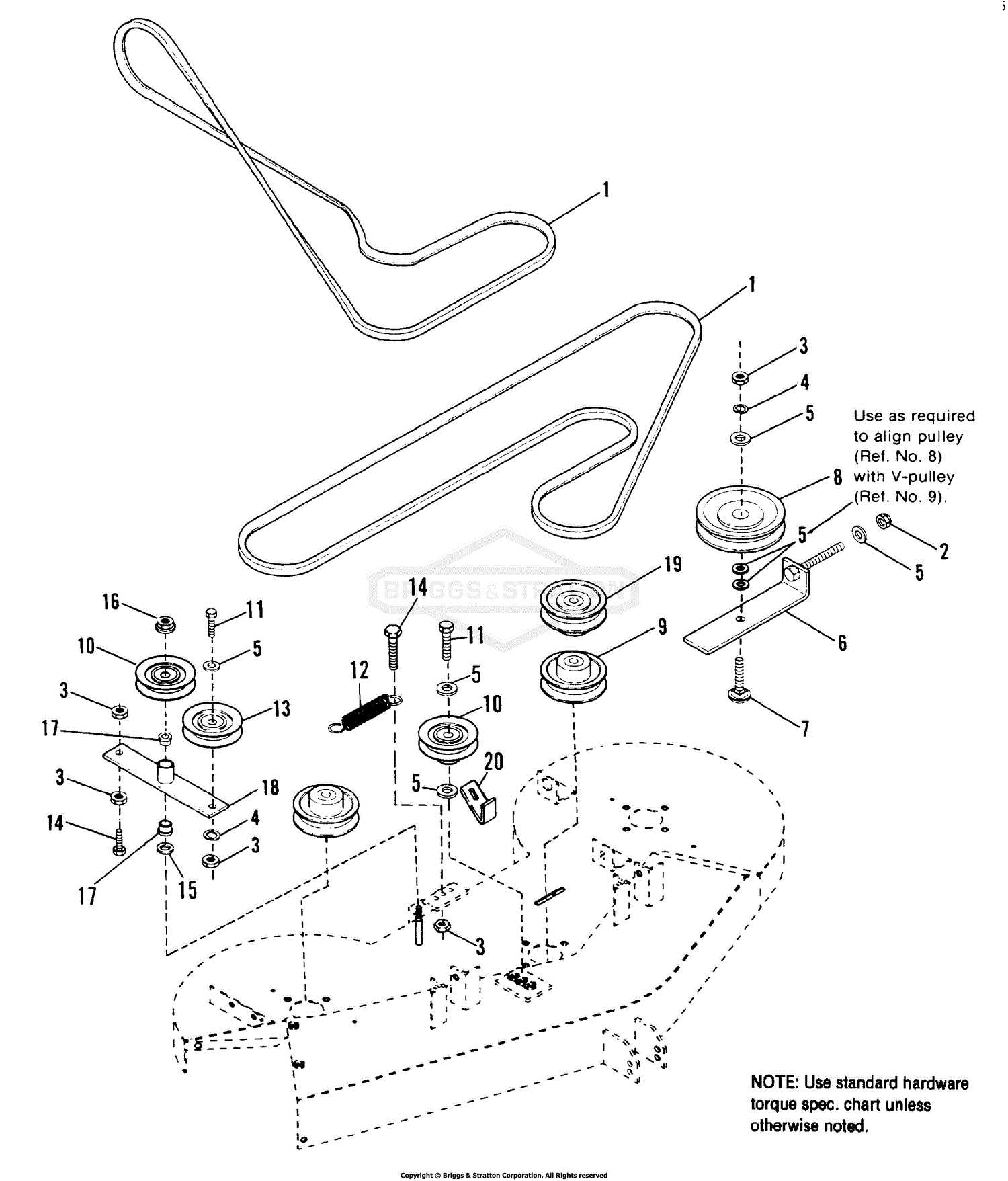

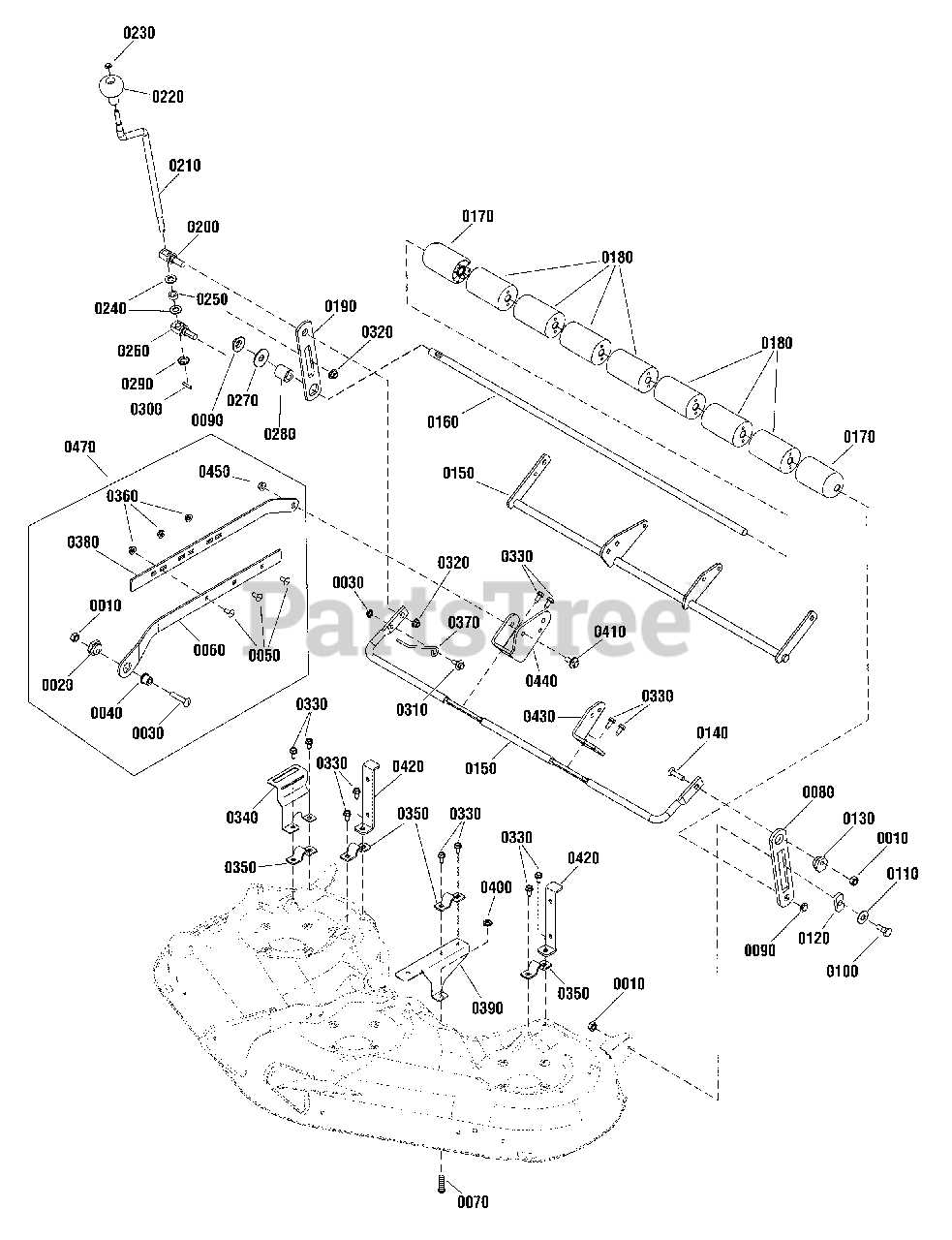

The key components typically include the cutting mechanism, drive system, and the support structure. The cutting mechanism is responsible for providing a clean, even cut, while the drive system helps power the machine forward. The support structure connects all the parts and provides stability during operation. Understanding each part’s role will help you recognize any issues that may arise.

Why Component Knowledge is Crucial

Having detailed knowledge of the components will not only help in troubleshooting but also aid in routine maintenance. Regular inspections of these parts can prevent wear and tear from becoming larger, more expensive problems. By being proactive, you can prolong the lifespan of your equipment and ensure its continued effectiveness.

How to Identify Key Lawn Equipment Components

Recognizing the critical elements of your outdoor machinery is an essential skill for any user. Proper identification ensures that you can maintain, repair, or replace the correct parts when necessary. This section will guide you in identifying the most important components and understanding their functions.

- Cutting Mechanism: This includes blades and the assembly that ensures precise cuts. It is crucial to regularly inspect for wear and tear.

- Power System: This consists of the engine and related components responsible for driving the equipment. A malfunction here can prevent the machine from operating.

- Support Frame: This is the structure that holds the components together and ensures stability during use. Check for any damage or loose connections to maintain balance.

- Drive Belt and Pulley System: These components transfer power from the engine to the cutting mechanism. Over time, they can wear out and may require replacement.

By learning to identify these parts, you can effectively troubleshoot any issues and perform essential maintenance, ensuring the machine remains in optimal working condition for a longer time.

Step-by-Step Guide to Lawn Equipment Maintenance

Proper care and maintenance are essential for keeping your outdoor machine in top condition. By following a structured approach, you can address common issues, prolong the life of your equipment, and improve its performance. This step-by-step guide will help you maintain the key components, ensuring smooth operation for years to come.

Start by turning off the engine and disconnecting any power sources. This ensures safety during the maintenance process. Once the machine is safely powered down, proceed with a thorough cleaning. Remove grass clippings and debris that may have accumulated around the cutting mechanism and underneath the machine. This helps prevent clogging and maintains the efficiency of the system.

Next, inspect the cutting elements for signs of wear. Sharpen the blades if necessary, or replace them if they are damaged. Check for any loose parts or bolts and tighten them to ensure stability during operation. It’s also important to lubricate the moving components to reduce friction and prevent premature wear.

Finally, check the drive system, belts, and pulleys for any signs of damage or wear. If the belts are cracked or worn out, replace them immediately to avoid any potential breakdowns. Regularly maintaining these areas will help keep your machine operating at peak performance.