Proper maintenance and repair of small engines are essential for ensuring optimal performance and longevity. Understanding the layout and components of the engine is the first step toward successful troubleshooting and repairs. A detailed visual reference of the engine’s internal parts can make the entire process much easier and more efficient.

In this guide, we will explore the structure of a specific engine model, providing insights into each key component and how they function together. Whether you are a DIY enthusiast or a professional mechanic, knowing the exact location and function of each part can save time and prevent costly mistakes during repairs.

By using a clear and organized reference, you can quickly identify any worn or damaged components, making it easier to order replacements and carry out the necessary repairs. This approach will not only extend the life of the engine but also improve its overall performance, ensuring it runs smoothly for years to come.

Understanding the Engine Model

A thorough understanding of an engine’s design and components is essential for effective maintenance and repair. Familiarizing yourself with the core elements of an engine will make it easier to identify issues, replace faulty parts, and ensure smooth operation. Each engine is built with a set of integrated systems that work together to generate power, and recognizing how these systems interact is key to troubleshooting effectively.

Key Engine Components

The engine contains several important sections that contribute to its function. Here are the main components that make up the internal structure:

- Fuel System: Responsible for delivering the fuel to the engine. Proper fuel delivery is crucial for smooth operation and performance.

- Ignition System: Includes spark plugs, ignition coils, and other elements that initiate the combustion process. A strong ignition system ensures the engine starts easily.

- Lubrication System: Keeps the internal parts of the engine properly lubricated to reduce friction and prevent wear.

- Cooling System: Maintains the engine’s temperature by circulating coolant or utilizing air cooling, preventing overheating and damage.

How the Systems Work Together

All systems in an engine are interconnected and rely on each other to ensure the engine functions properly. For instance, fuel and ignition systems must work in sync to create combustion. Meanwhile, the cooling and lubrication systems maintain optimal operating conditions to avoid excessive wear. If one system fails or becomes inefficient, it can impact the entire engine’s performance. Understanding how each part contributes to the whole will allow you to perform better diagnostics and repairs.

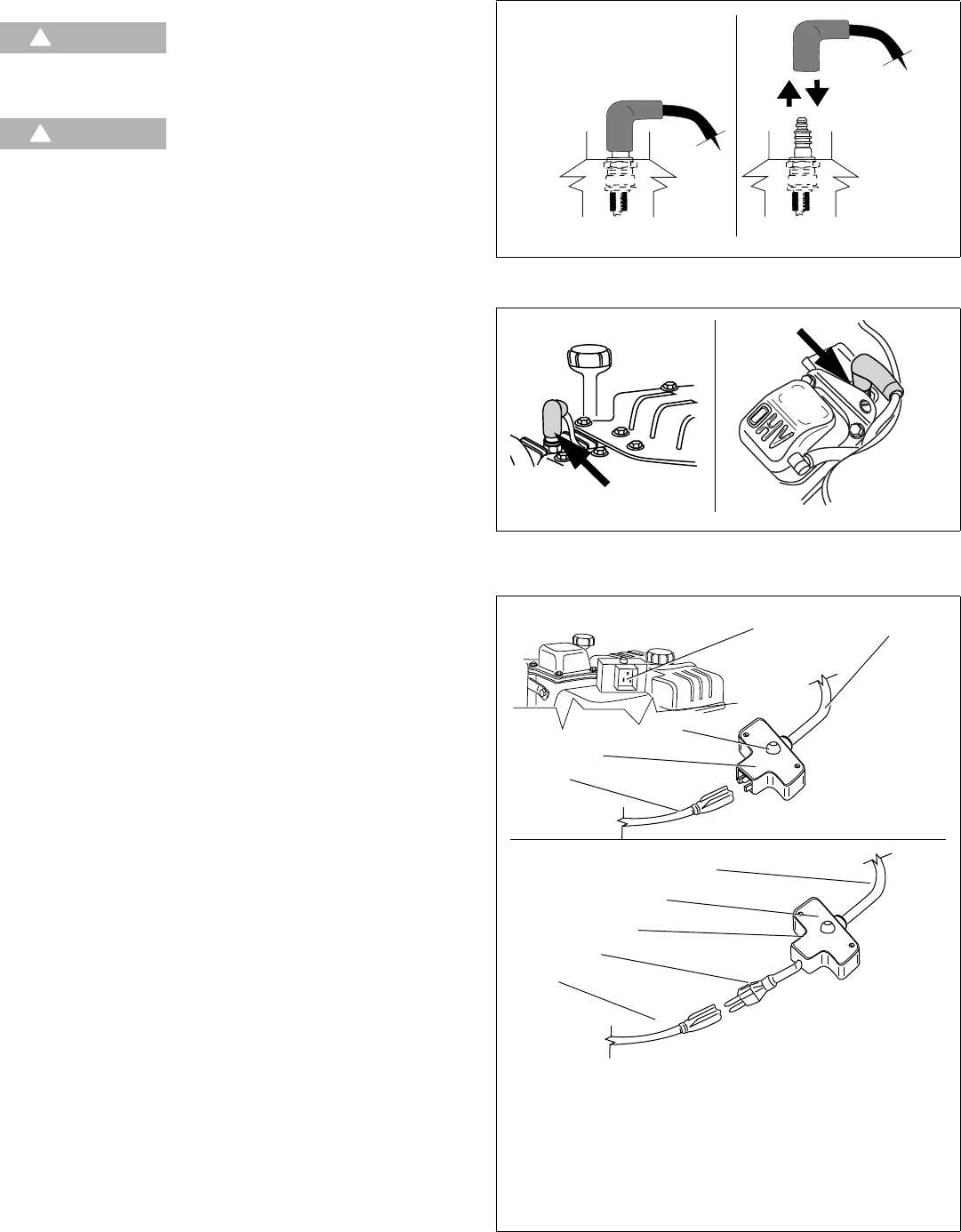

Identifying Key Parts in the Diagram

To effectively repair or maintain an engine, it’s crucial to understand the layout and structure of its components. A well-organized visual reference allows you to quickly locate key elements, ensuring that any worn or damaged parts can be replaced efficiently. By identifying the primary components, you can focus on the specific areas that need attention, streamlining the repair process.

Each section of the engine serves a unique function, and recognizing these elements is essential. With the right reference, you can easily pinpoint the following important components:

- Carburetor: Responsible for mixing air and fuel before it enters the combustion chamber.

- Cylinder Head: Houses the valves and helps control the intake and exhaust cycles.

- Crankshaft: Converts the linear motion of the piston into rotational motion, powering the engine.

- Flywheel: Maintains the engine’s momentum and stabilizes the rotational speed during operation.

- Valves: Control the intake of air/fuel mixture and exhaust gases from the engine’s cylinders.

Understanding where each of these components is located and how they interact within the engine can greatly improve the efficiency of your maintenance efforts. A clear diagram or reference guide makes it easier to identify any part that needs attention and ensures that repairs are done properly and in a timely manner.

How to Use the Parts Diagram Effectively

Utilizing a visual guide for engine components is a powerful tool for troubleshooting, repairs, and maintenance. By having a clear and detailed reference, you can pinpoint issues more quickly, ensuring that you replace only the necessary components. Understanding how to read and interpret this guide will save you time and reduce the risk of errors during the repair process.

To make the most out of this reference, follow these steps:

- Familiarize Yourself with the Layout: Take some time to review the entire reference so you can get a sense of where each component is located and how they interact.

- Identify Key Components: Focus on the main elements that need attention. Whether it’s a worn-out part or an area showing signs of wear, knowing the correct name and location of each piece is critical.

- Follow the Flow: Understand how systems work together, such as fuel flow, airflow, and exhaust systems. This can help in diagnosing issues more efficiently.

- Cross-reference with Manuals: When in doubt, check the engine’s manual for additional specifications and part numbers to ensure compatibility with your reference.

- Use for Disassembly and Reassembly: A diagram is also incredibly helpful when taking apart the engine. It can guide you through the correct sequence for reassembling the components after a repair.

By following these steps, you can streamline the repair process, avoid unnecessary confusion, and complete the work with greater confidence and accuracy.