Maintaining your carpet cleaning machine requires a basic understanding of its internal mechanisms. When something goes wrong, having access to a detailed visual guide of its elements can make repairs and maintenance much easier. This can save you time and effort when troubleshooting or replacing worn-out parts.

Each model comes with specific features that require attention over time. Identifying the right components and knowing how they fit together is crucial for keeping the equipment in optimal working condition. In this section, we’ll explore how to navigate and understand the crucial parts of your cleaner.

Efficient maintenance ensures that your device operates smoothly, preventing unnecessary breakdowns. Whether you’re dealing with a malfunction or simply need to replace a worn piece, a clear understanding of your machine’s layout will make the process straightforward.

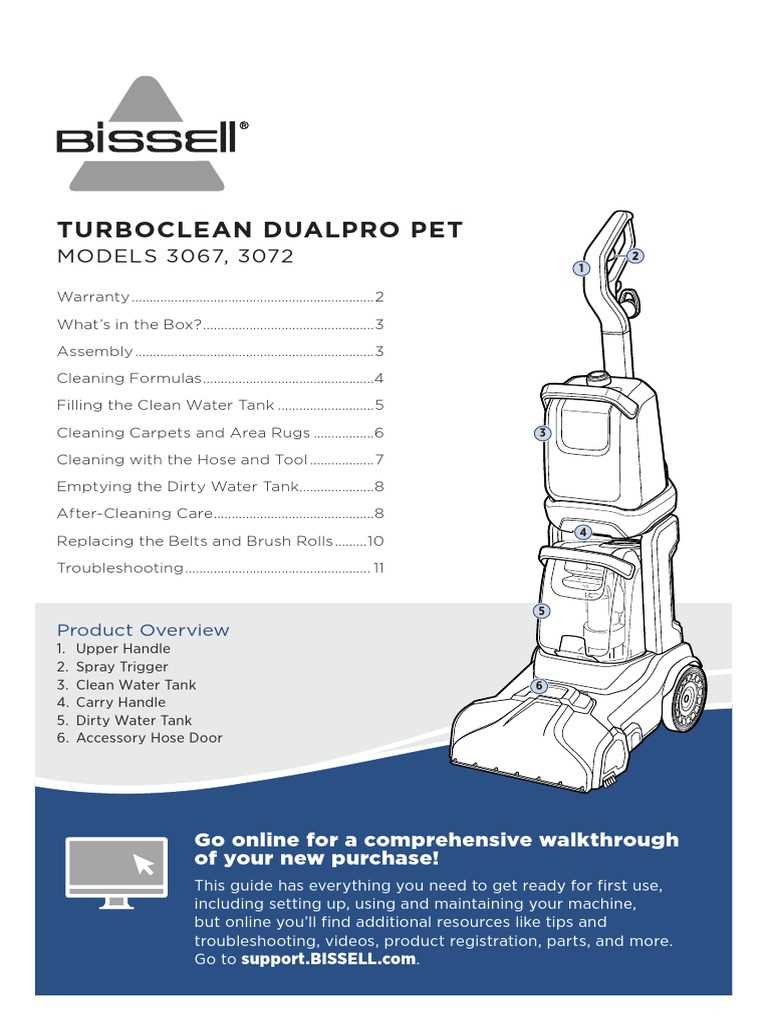

Understanding Carpet Cleaner Components

Every carpet cleaning machine consists of various essential elements that contribute to its effective functioning. From the motor to the cleaning brushes, each part plays a significant role in ensuring the device performs optimally. Familiarizing yourself with these components can simplify maintenance, help in troubleshooting, and ensure the longevity of the equipment.

Key Elements of the Cleaning System

The primary function of a carpet cleaner is to scrub and extract dirt from deep within fibers. This is achieved through a combination of rotating brushes, suction mechanisms, and water delivery systems. Understanding how these systems interact can give you a better idea of where potential issues may arise, and how to address them efficiently.

Maintenance and Replacement Tips

Over time, some components may wear out or become clogged with debris. Regular maintenance such as cleaning the brushes, replacing worn seals, or clearing any blockages in the suction channels will help maintain peak performance. Knowing how to replace certain elements and when to act will ensure your equipment remains reliable and effective for the long term.

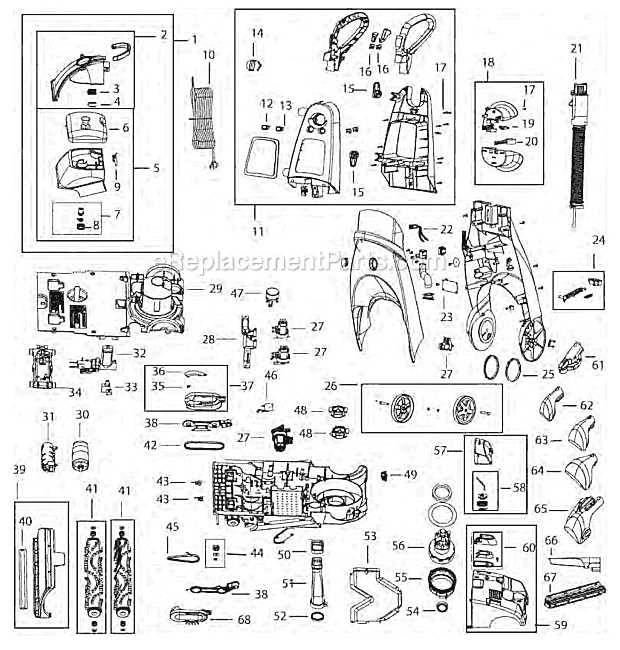

How to Read the Parts Diagram

Understanding the layout of your cleaning device can greatly simplify any repair or maintenance process. A visual reference, showing the arrangement of key components, allows you to quickly identify each part and its function. Learning how to interpret this guide is essential for diagnosing problems and replacing damaged items accurately.

These visual aids typically include labels or numbers corresponding to individual components. By matching these with the accompanying list or manual, you can easily locate the part you need to inspect or replace. Whether you’re looking for a specific element or trying to understand the entire setup, knowing how to read this reference is crucial for efficient upkeep.

Common Issues and Replacement Parts

Over time, any cleaning equipment may face wear and tear, which can affect its performance. Recognizing the most frequent issues and knowing which components require replacement can help maintain the machine’s efficiency. Understanding these common problems allows for quicker resolutions and ensures that the device continues to operate effectively.

Frequent Malfunctions

Some of the most common issues include loss of suction, malfunctioning brushes, and clogged hoses. These problems are often caused by debris buildup, worn seals, or damaged components that hinder the device’s ability to clean efficiently. Identifying these signs early can prevent more serious damage and restore your machine’s performance.

Replacing Worn Components

When components become worn out or damaged, replacing them promptly is essential to avoid further complications. For example, seals, belts, or cleaning rollers may need to be swapped out to ensure the machine continues to function optimally. Having access to a comprehensive guide of components helps you quickly find the correct replacement parts and maintain your cleaner’s longevity.