In any cutting machine, the efficiency and accuracy depend largely on the individual elements that work together. These elements, often intricate in design, each serve a distinct role in ensuring smooth operation. Recognizing how they interconnect can significantly improve the user’s understanding and handling of the equipment.

Each component is vital to the overall performance, contributing to both the power and precision of the system. Whether it’s the flow of energy or the transfer of force, the right combination of elements ensures that tasks are completed effectively. This section will guide you through the main parts of the system and their functions, allowing for a deeper understanding of their roles.

Familiarizing yourself with these crucial components is not only useful for troubleshooting but also for routine maintenance and upgrades. As you explore their functions, it becomes clear how each part influences the outcome of every operation, making it essential for optimal performance.

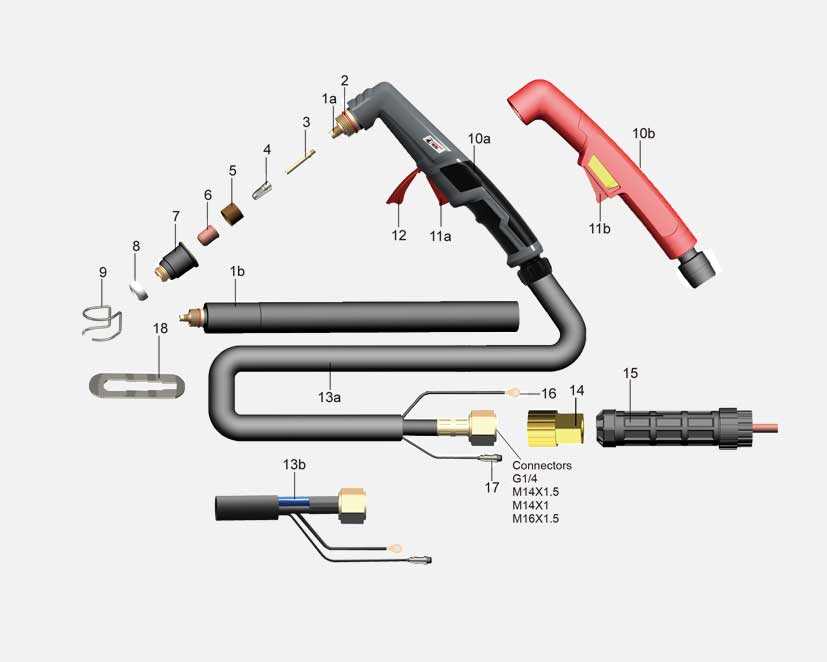

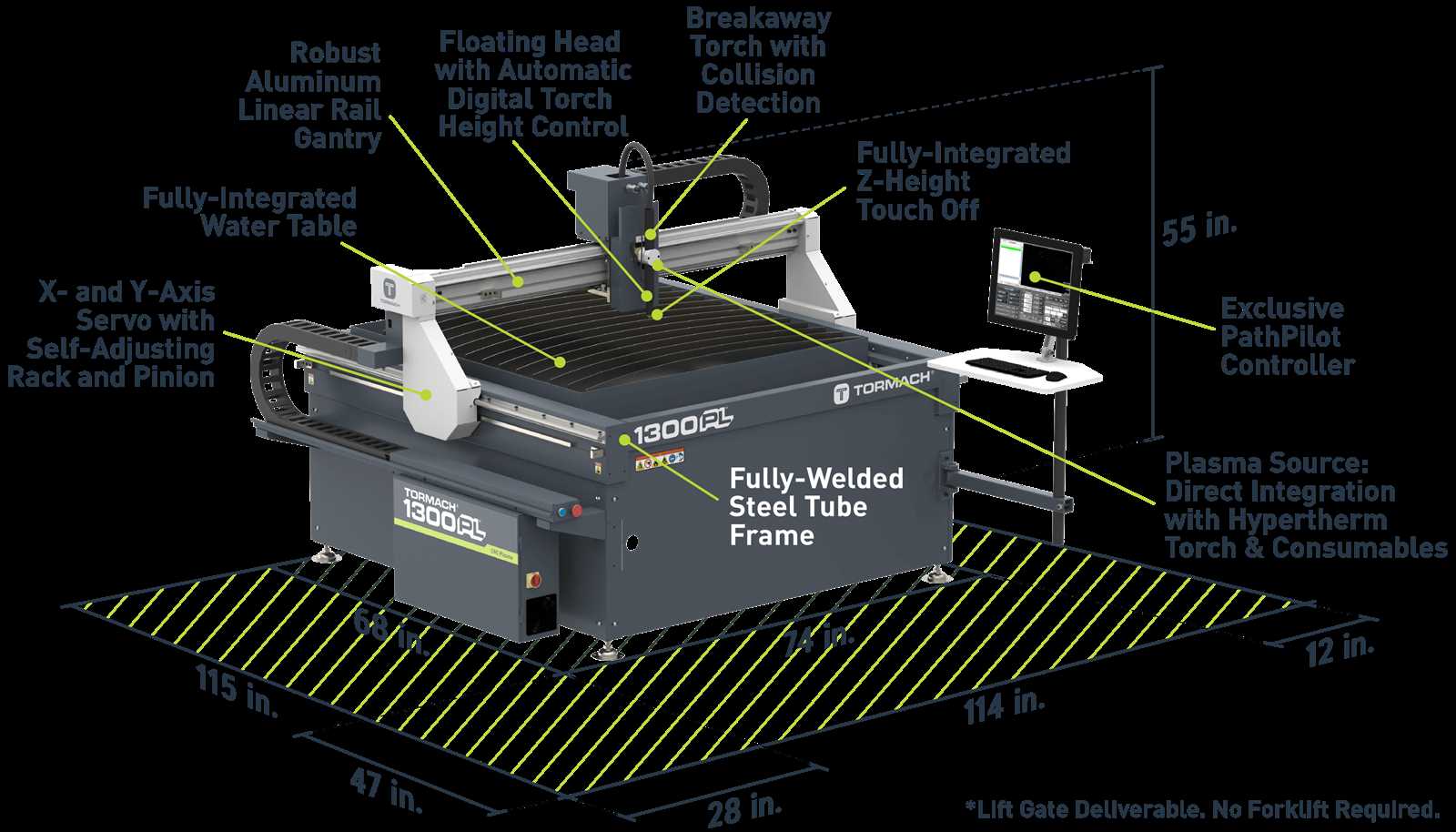

Understanding Plasma Cutter Components

The efficiency of any cutting system relies heavily on the individual elements that make up its structure. These components, working in harmony, enable the machine to operate at its best, allowing for precise cuts and optimal functionality. By gaining a deeper understanding of these components, users can enhance their performance and troubleshoot problems more effectively.

Core Elements of the System

At the heart of the operation lies the power source, which provides the necessary energy to initiate the cutting process. Alongside it, the delivery system directs the flow of energy and materials, ensuring a stable and consistent performance. Other essential elements, such as control mechanisms, regulate the power and speed, giving the operator full command over the operation.

Supporting Mechanisms

Supporting parts, including the cooling and filtration systems, play a crucial role in maintaining the longevity and efficiency of the equipment. These mechanisms ensure that the system runs smoothly, preventing overheating and blockages, which could otherwise disrupt the cutting process. Their proper functioning is key to avoiding breakdowns and ensuring that the equipment performs as expected over time.

Key Parts and Their Functions

Every machine consists of crucial components that each serve a specific role in its overall performance. Understanding how these key elements function individually and together allows users to maximize efficiency, troubleshoot issues, and maintain the equipment for prolonged use. This section explores some of the most important elements that contribute to the smooth operation of the system.

Energy Source and Regulation

The primary energy source is vital for powering the system, supplying the necessary force for cutting. The regulator then ensures that the energy is consistently delivered in the correct amounts. This coordination of energy flow is essential for maintaining stable performance and achieving precise results.

Material Flow and Direction

Equally important is the system that directs the flow of materials, ensuring that they are properly positioned and controlled throughout the cutting process. This includes mechanisms that guide the flow of gases and transfer heat efficiently. The smooth movement of materials is key to both speed and accuracy during operation.

How to Identify Plasma Cutter Issues

Identifying issues with the machine early on can prevent more serious malfunctions and ensure smooth operation. Recognizing common signs of trouble allows users to troubleshoot efficiently and maintain optimal performance. This section outlines some of the most frequent problems and how to spot them quickly.

Common Symptoms of Malfunctions

- Inconsistent Cuts: If the machine struggles to make even, smooth cuts, it could be due to issues with energy flow or the material movement system.

- Overheating: An overheated system may indicate a problem with the cooling mechanism or prolonged operation without breaks.

- Erratic Power Supply: Flickering or uneven energy could suggest a fault in the regulator or power source.

How to Troubleshoot Effectively

- Check Connections: Ensure all connections are secure, especially between power and control elements.

- Inspect Cooling System: Verify that the cooling system is functioning properly to avoid overheating.

- Examine Material Flow: Ensure that materials are being fed properly and without obstruction.