When working with welding equipment, knowing the different elements and their functions is crucial for both effective use and maintenance. Identifying individual components allows for easier troubleshooting and ensures optimal performance over time. A comprehensive guide to understanding the key pieces of a welder can help both professionals and beginners alike maintain their tools and make informed repair decisions.

Proper knowledge of your equipment’s inner workings can prevent unnecessary damage and costly repairs. By familiarizing yourself with each piece and how they interact, you can ensure smooth operation and extend the lifespan of your tool. This guide will provide a breakdown of the main components, highlighting their roles and offering tips for upkeep and replacements.

By understanding the layout and construction of your welder, you’ll be equipped to handle maintenance tasks with confidence. Whether you are performing routine checks or facing an issue, knowing how each part contributes to the overall function can save time and effort.

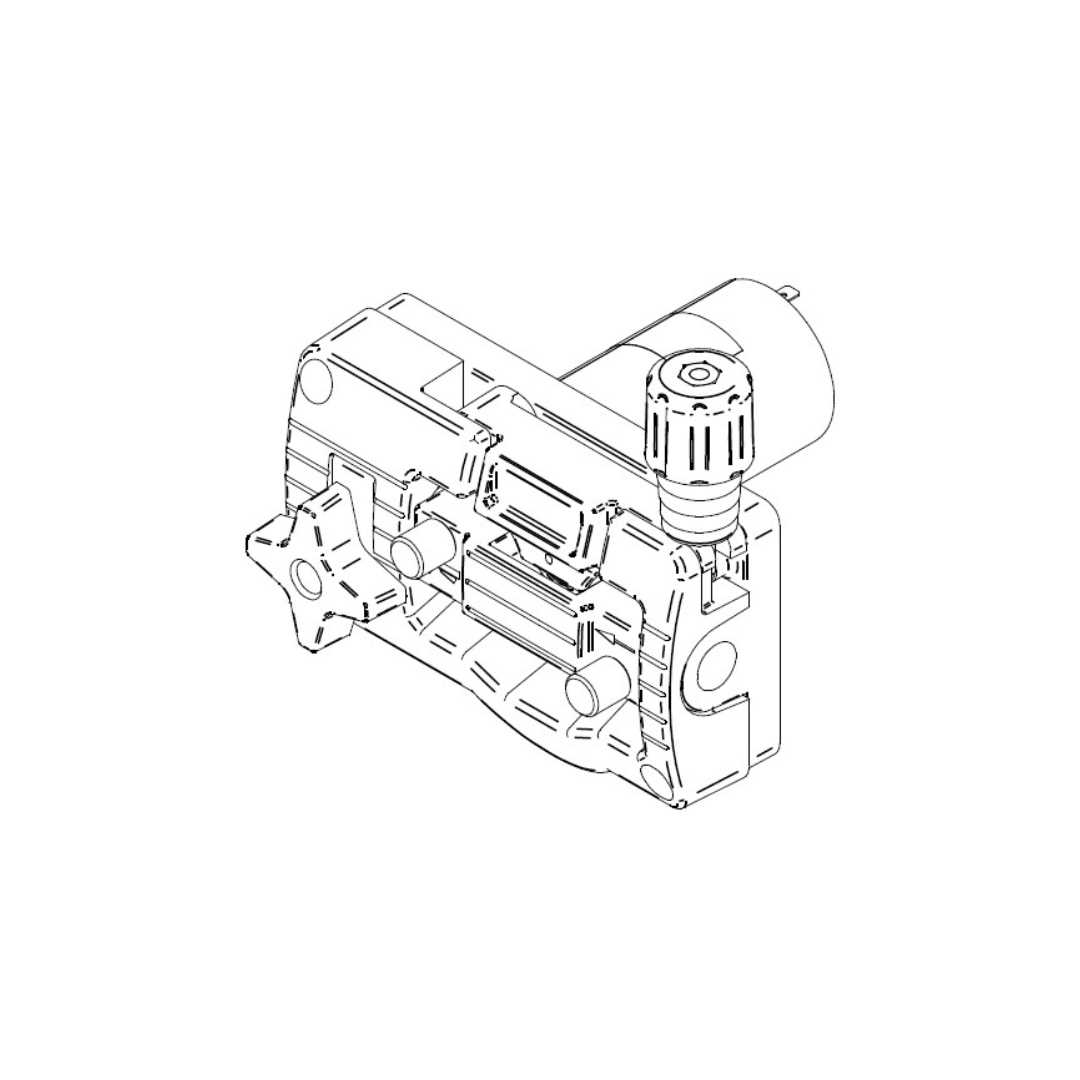

Understanding the Lincoln 210 MP Parts

Every welding machine consists of various key components, each playing an essential role in its overall functionality. Whether you are using the equipment for professional or hobbyist purposes, a clear understanding of how these pieces work together will help you maintain the device effectively. From the power source to the control mechanisms, knowing how each section contributes to the welding process is crucial for optimal performance.

Each element serves a distinct purpose, from ensuring consistent power delivery to managing heat and maintaining the stability of the arc. Regular maintenance and periodic checks can prevent common failures that may arise from wear and tear. Having the right knowledge allows users to quickly identify malfunctioning parts, leading to faster repairs and reducing downtime.

By grasping how each individual piece functions, you gain a deeper insight into troubleshooting and efficient maintenance practices. This understanding helps ensure that your welding tool remains in top condition, ready to perform at its best whenever needed.

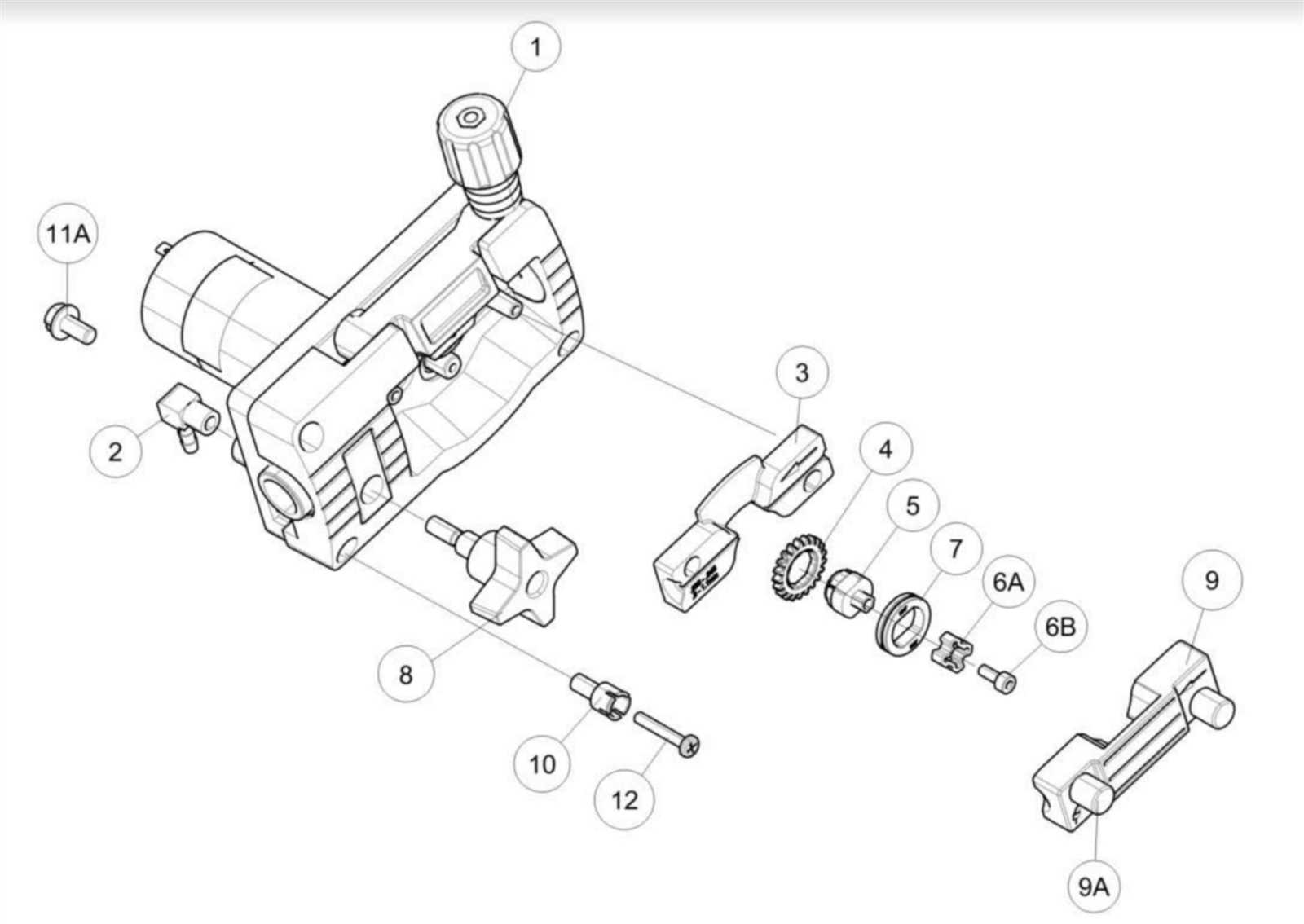

How to Read a Parts Diagram

Understanding a schematic or visual representation of a device’s components is essential for effective maintenance and repair. These illustrations provide clear details about the various elements within the equipment, showing how they are arranged and interconnected. Learning to read these guides can simplify troubleshooting, enabling users to quickly pinpoint issues and take appropriate action.

Identify the Key Elements

Before diving into repairs, it’s important to recognize the symbols and labels used in the schematic. Each section will typically have labels corresponding to individual components, helping you understand their function. Some diagrams will include a numbered list or reference guide that links the visual elements to their respective parts, making it easier to locate and identify each one in your machine.

Understand the Flow of the System

In addition to identifying individual components, it’s crucial to understand how they interact within the system. A diagram will often display how energy flows through the device or how different parts work together to complete a task. Recognizing the connections between components can guide you in diagnosing problems and assembling or disassembling the device correctly.

Common Issues and Replacement Parts

As with any piece of machinery, regular use can lead to wear and tear, causing certain components to fail or lose efficiency. Understanding the most common issues that arise in welding equipment is essential for prompt repairs and minimizing downtime. Identifying these problems early on can help ensure the longevity of the machine and maintain its performance.

Some frequent malfunctions include overheating, inconsistent power supply, or issues with the control settings. Over time, certain components may wear out or become damaged, requiring replacement to restore the tool’s full functionality. By knowing which parts are most likely to need attention, you can be proactive in replacing them before they cause more serious problems.

Commonly replaced components include the power cables, cooling fans, and internal connectors. Regular inspection and proper maintenance can help extend the lifespan of these parts, preventing frequent breakdowns and costly repairs. Having a reliable set of replacements on hand ensures that you can keep your equipment in top working condition at all times.