Every motorized vehicle consists of various interconnected elements that work together to ensure smooth performance. Having a clear understanding of these components can help with maintenance, repairs, and upgrades. Whether you are a novice or an experienced rider, it’s crucial to familiarize yourself with the layout of the system to address issues efficiently and safely.

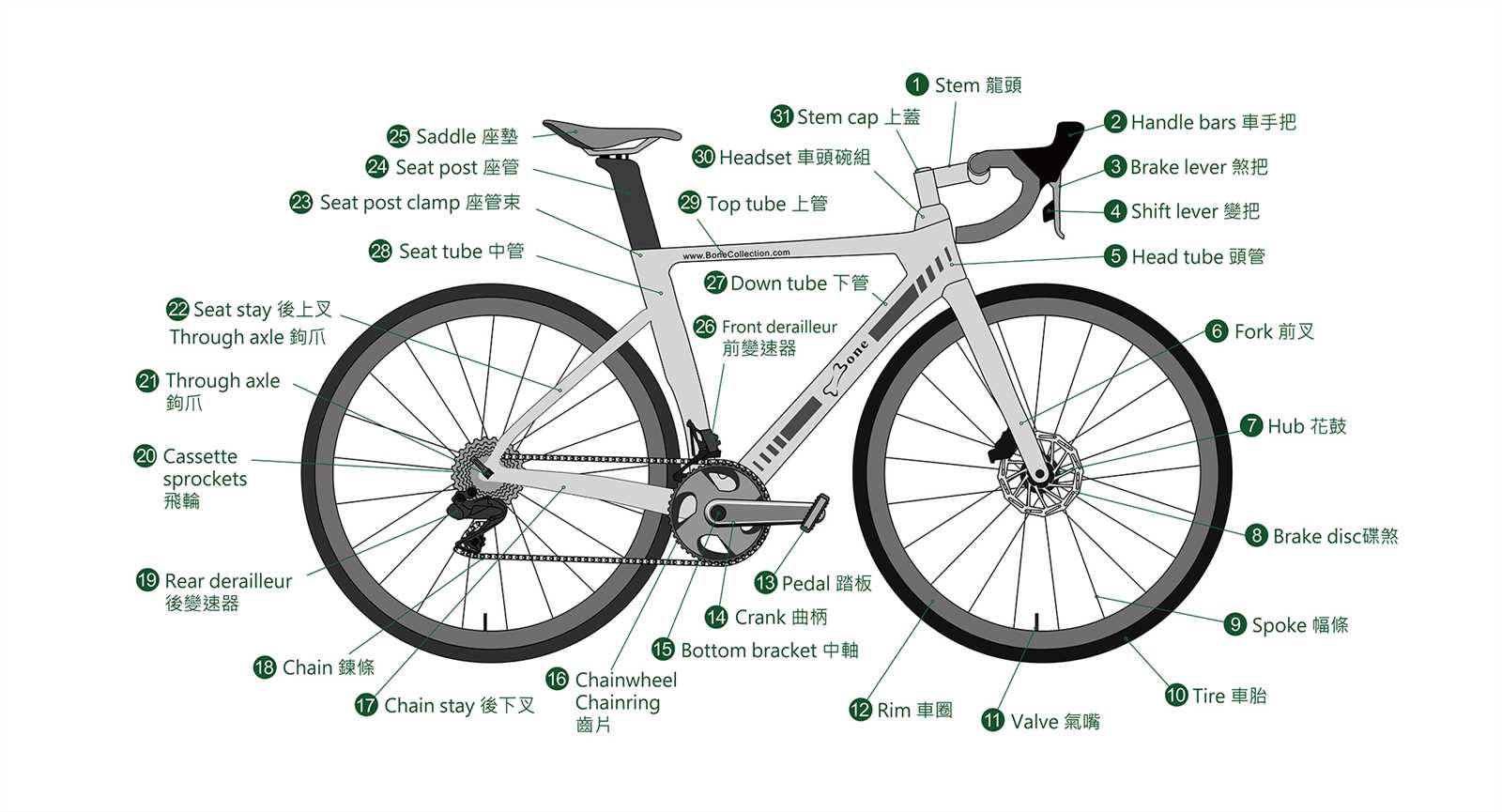

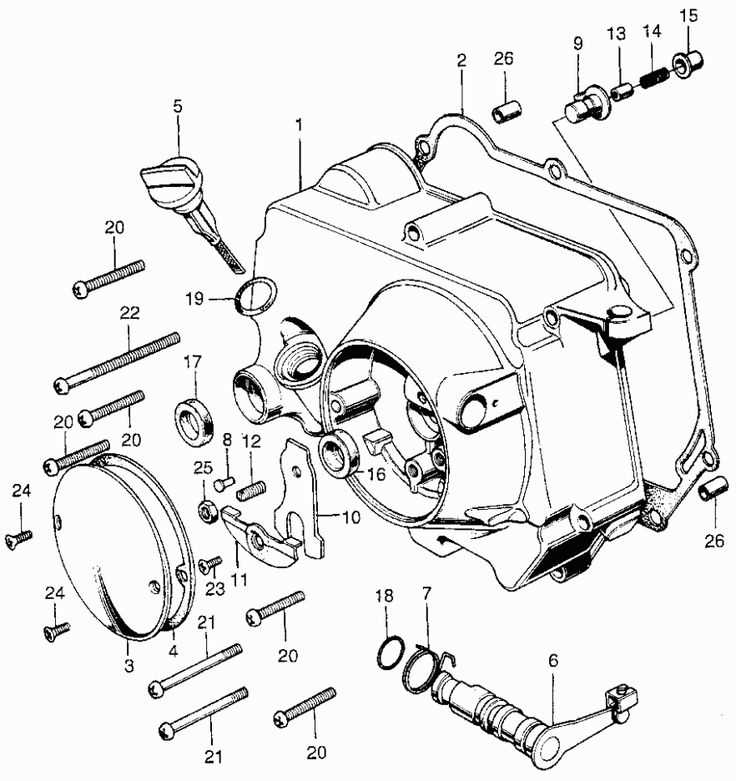

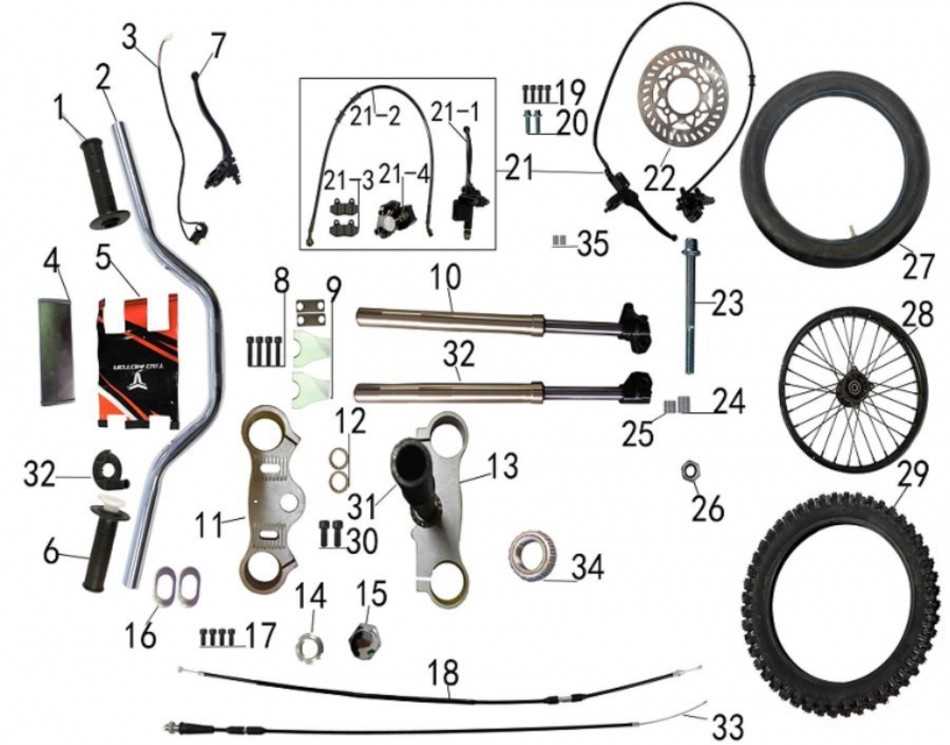

Identifying each part is the first step in diagnosing problems and performing proper maintenance. By knowing the role of each individual component, you can better assess its condition and determine the necessary actions for improvement.

Knowing the structure also empowers you to make informed decisions when modifying or replacing parts, ensuring that the vehicle operates at its highest potential. This knowledge enhances both the longevity and the performance of your machine, reducing the risk of costly mistakes.

Understanding Motorized Vehicle Component Layout

Every mechanical system relies on a well-organized structure, with each element serving a specific function to ensure optimal operation. Understanding this layout is essential for anyone looking to maintain, repair, or upgrade the system effectively. A clear grasp of how each section contributes to the overall performance can significantly improve the user’s experience and troubleshooting skills.

Key Structural Elements

The framework of a motorized machine typically includes the engine, suspension, and control systems, all of which are crucial for mobility and safety. These systems interact with one another, creating a balanced structure that allows for efficient movement and handling. Recognizing the function of each part within this larger structure helps pinpoint issues and facilitates smoother operations.

Connecting Systems for Performance

In addition to the primary components, auxiliary systems like the exhaust, fuel delivery, and electrical units play significant roles in maintaining performance. Understanding how these secondary elements fit within the larger system is essential for making informed decisions during repairs or modifications. This knowledge contributes to better diagnostics and overall vehicle upkeep.

Key Components in a Motorized Vehicle Layout

Understanding the essential elements of a mechanical system is crucial for efficient operation and maintenance. Each individual component works in harmony with others to ensure smooth performance, and knowing their functions helps in making informed decisions about repairs and upgrades. In this section, we’ll explore the key elements that form the backbone of the vehicle’s structure.

Engine and Powertrain

The engine is the heart of the system, responsible for generating power. It connects to the powertrain, which transfers energy to the wheels, enabling motion. The efficiency of the engine and powertrain is essential for maintaining speed and handling, making them critical components in any machine. Regular inspection of these systems is necessary to ensure they remain in optimal working condition.

Suspension and Handling Systems

Suspension systems are designed to absorb shocks and provide stability, ensuring smooth handling on various terrains. These components, which include shocks, forks, and linkages, are essential for controlling movement and providing rider comfort. A well-maintained suspension system significantly enhances control, especially in rough or uneven environments.

How to Use a Motorized Vehicle Component Layout

Understanding how to interpret a system layout is key to performing maintenance or repairs effectively. A well-organized schematic can guide you in identifying the exact location of each element and its relationship to others. Knowing how to read and use these layouts makes diagnosing issues and assembling parts much easier, allowing for more efficient work.

The first step is to familiarize yourself with the layout’s structure. Most schematics will clearly mark each component, often using numbers or labels for easy identification. Start by reviewing the major systems such as the engine, fuel system, and suspension, and get a sense of how they connect. Understanding these connections will give you the foundation needed for effective troubleshooting.

Once you have a general sense of the layout, use it as a reference during maintenance or repair tasks. If you need to replace a part or assess the condition of a specific component, the layout can provide clear guidance. Knowing which parts are connected and how they interact ensures that your actions are precise, minimizing the risk of errors.