For any efficient water circulation system, knowing the individual components that keep everything running smoothly is essential. The operation of these systems depends on a well-coordinated interaction of various elements working together. Each part has a specific function that ensures the entire system performs optimally.

Whether you’re maintaining an outdoor water feature or a large filtration setup, it’s important to understand how each element contributes to the overall efficiency. This knowledge helps in troubleshooting, maintenance, and selecting the right components when replacement is needed.

Identifying and comprehending the roles of each component ensures long-lasting performance and minimizes potential issues. In this guide, we will explore the essential elements that make up a functional system, highlighting their roles and how they contribute to the overall functionality.

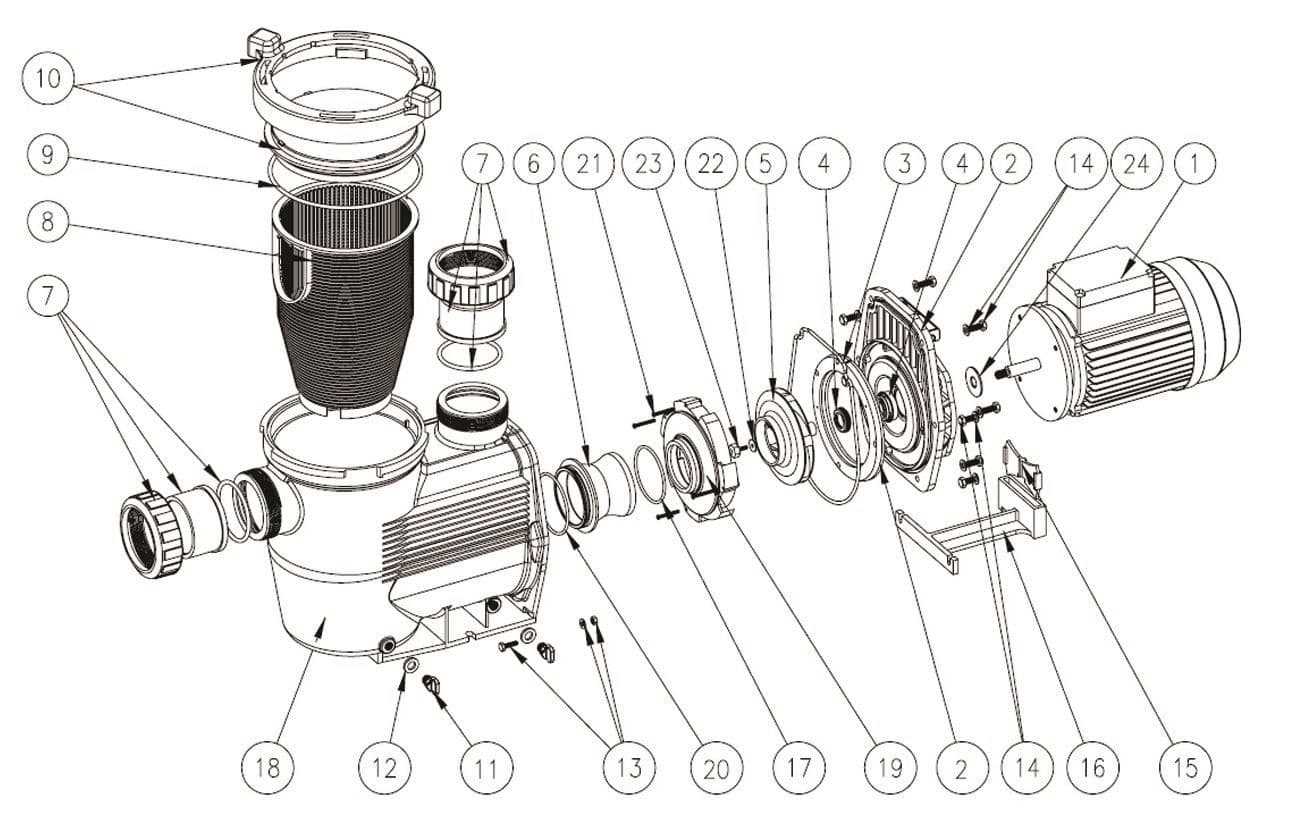

Key Water Circulation System Components Explained

Understanding the core elements of any water circulation system is crucial for maintaining its efficiency. Every system relies on a combination of components, each contributing to smooth and uninterrupted operation. The proper functioning of these parts ensures the system remains effective, minimizing disruptions and maximizing performance.

Essential Elements for Effective Operation

Below are the primary components that play a vital role in keeping the system running smoothly:

- Motor – Provides the power needed to operate various elements and maintain the flow.

- Impeller – Moves water throughout the system, creating the necessary pressure for circulation.

- Strainer – Filters debris and ensures clean water is passed through the system.

- Filter – Removes impurities from the water, ensuring that the flow remains clean and efficient.

- Volute – Houses the components that direct the water flow, helping to maintain pressure and manage distribution.

How These Components Work Together

These elements are not standalone; they interact with each other to ensure optimal performance. The motor powers the impeller, which moves the water and sends it through the strainer and filter. As the water circulates, it passes through various channels designed to ensure even distribution and proper flow. Each part must be maintained to avoid performance degradation or malfunction.

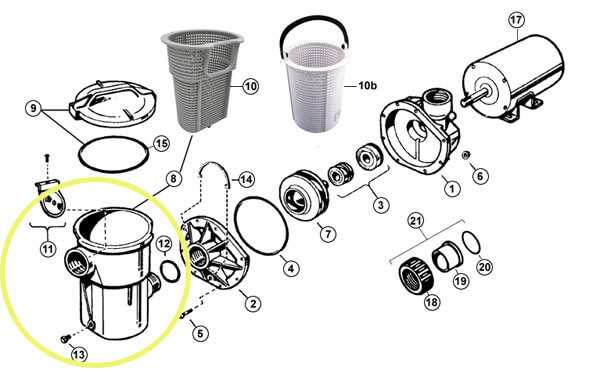

Understanding the Function of Each Part

Each component within a water circulation system serves a specific purpose, working in harmony to maintain continuous flow and filtration. The efficiency of the entire system relies on the proper functioning of every individual element. Understanding the role of each part allows for effective troubleshooting, maintenance, and overall system optimization.

Key Roles in the System

The main elements responsible for ensuring a reliable and smooth operation include:

- Motor – Provides the energy required to drive the entire system, powering all components.

- Impeller – Moves the water through the system, ensuring circulation and maintaining flow pressure.

- Strainer – Traps larger debris and particles, preventing clogging and ensuring cleaner water enters the system.

- Filter – Removes fine impurities, ensuring the water remains clean and clear as it circulates.

- Volute – Directs the water flow, maintaining pressure and ensuring smooth water movement through the system.

How the Parts Interact

These components work together seamlessly. The motor powers the impeller, which pushes water through the strainer and filter. The flow is then directed through the volute, ensuring consistent pressure and distribution. The proper functioning of each element is crucial to maintain an efficient and effective system that meets all operational requirements.

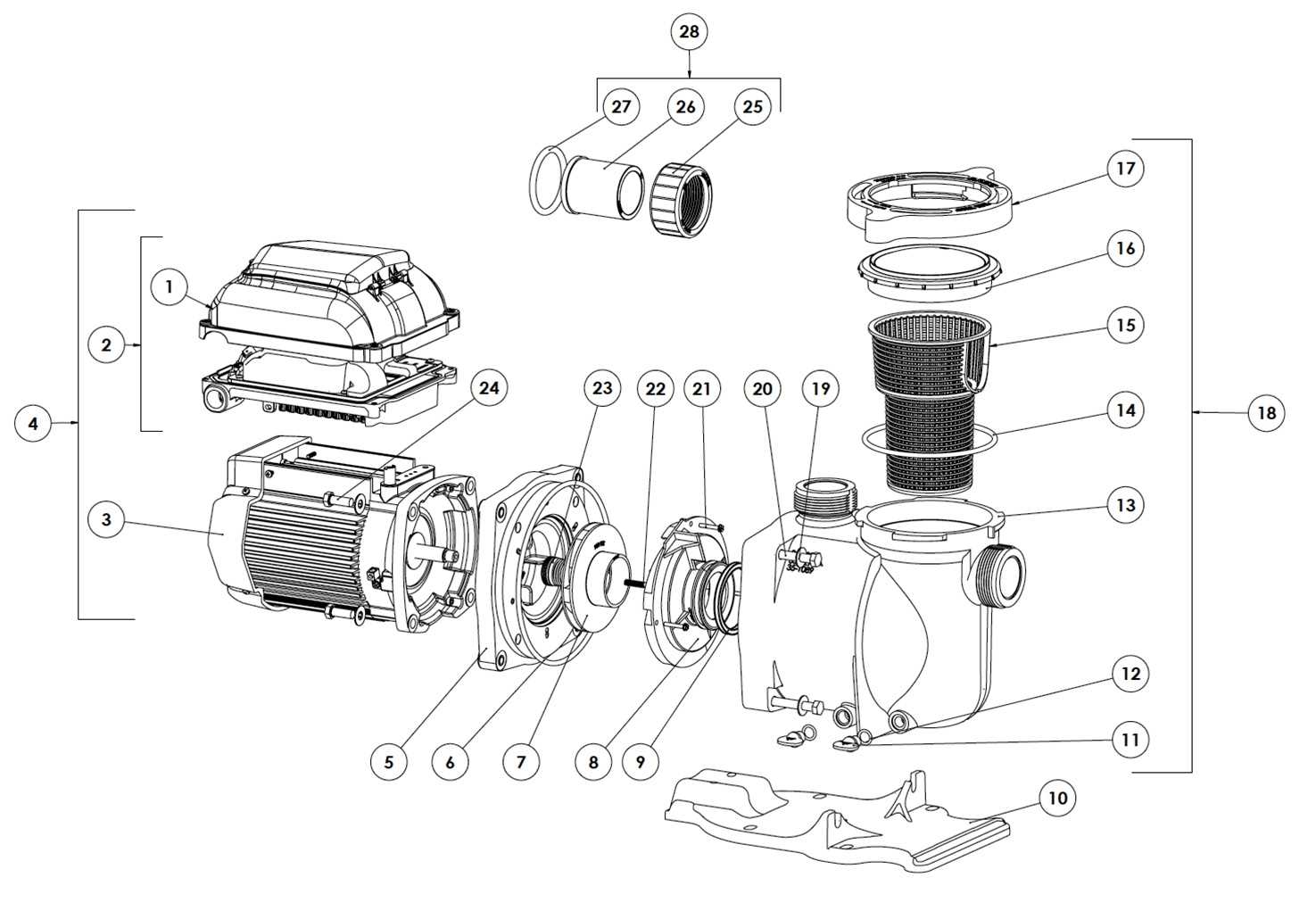

How Water Circulation Systems Operate Efficiently

The efficiency of a water circulation system depends on how well its components work together. Proper coordination between each element ensures that water flows continuously without disruption, while maintaining the desired filtration and circulation rates. A well-maintained system can significantly reduce energy consumption and improve overall functionality.

In order to achieve efficient operation, the motor must drive the system components at the right speed, while the water flow is carefully managed through the various channels and filters. Each element must be in good condition to avoid unnecessary strain and maintain peak performance.

Key Factors for Efficient Operation

| Component | Function | Efficiency Impact |

|---|---|---|

| Motor | Provides power to all components | A well-maintained motor ensures consistent operation without energy waste. |

| Impeller | Moves water through the system | Optimized impeller performance reduces energy consumption while maintaining strong water flow. |

| Strainer | Prevents debris from entering the system | A clean strainer improves water flow and protects other components from damage. |

| Filter | Removes impurities from the water | Regular cleaning ensures that water stays clean without straining the system. |

| Volute | Guides water flow and maintains pressure | Proper alignment ensures smooth water movement and avoids pressure drops. |

Maintaining balance and monitoring each part’s efficiency are key to preventing system breakdowns and ensuring long-lasting performance. Regular inspection and upkeep can significantly extend the life of the system while reducing overall energy costs.

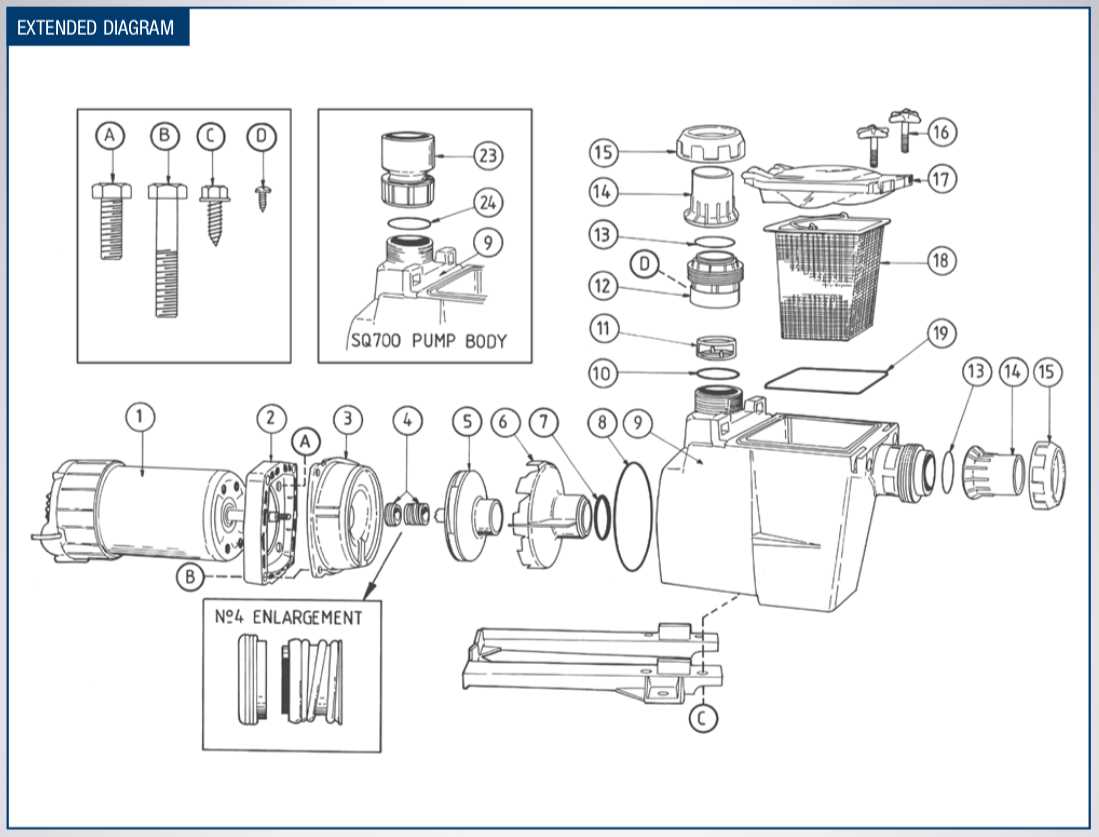

The Role of Every Element in the System

Each element within a water circulation mechanism plays a unique and vital role to ensure the entire system operates effectively. These components must work in harmony to maintain a continuous flow, remove impurities, and ensure the proper pressure is sustained throughout the process. A malfunction in any one of these elements can result in decreased performance or system failure.

Essential Functions of Key Components

Here is an overview of the critical functions performed by the primary elements:

- Motor – Serves as the driving force, providing the energy needed to operate the entire system.

- Impeller – Facilitates the movement of water, creating the necessary flow and pressure for circulation.

- Strainer – Captures larger debris, preventing clogs and ensuring the system remains free of obstructions.

- Filter – Purifies the water by removing fine contaminants, keeping it clean and clear.

- Volute – Directs the water flow, maintaining pressure and ensuring an even distribution throughout the system.

Coordinated Action for Optimal Performance

For the system to function smoothly, all these parts must work together without interference. The motor powers the impeller, pushing water through the strainer and filter. Once the water is filtered, the volute ensures that it moves in the right direction, maintaining the necessary pressure. Proper maintenance of each element guarantees that the system remains efficient and free from unnecessary wear and tear.

Identifying Common System Issues

Understanding the common issues that can arise in water circulation systems is essential for quick diagnosis and effective resolution. Many problems are related to inefficiencies or malfunctions in the system’s components. Identifying these issues early can prevent costly repairs and downtime, ensuring the system runs smoothly for longer periods.

While some issues are easy to spot, others may require a more detailed examination. Common signs of trouble include irregular flow, unusual noises, or water quality problems. By understanding the root causes of these issues, it becomes easier to pinpoint which component may need attention.

Common Problems and Their Causes

- Weak Flow – Often caused by clogs in the strainer or filter, or a malfunctioning motor.

- Excessive Noise – Can be due to an impeller imbalance or worn bearings in the motor.

- Low Pressure – A drop in pressure may result from a blocked filter or issues with the volute.

- Water Contamination – This could be due to a malfunctioning filter that is not effectively removing impurities.

- Overheating – Occurs when the motor is overworked or lacks proper ventilation.

Troubleshooting Tips

Regular maintenance checks can help prevent many of these issues. Ensure all components are clean and functioning as intended. If you notice any irregularities, such as unusual noises or poor flow, inspect the system for blockages or wear. In some cases, professional servicing may be required to address more complex problems.