A reliable lawn tractor requires precise mechanical components that ensure smooth handling and efficient operation. Whether you’re using your machine for basic yard care or heavy-duty tasks, knowing how each element functions is essential to maintaining its overall performance.

For optimal use, it is crucial to understand the different components involved in controlling your vehicle. Regular inspection and maintenance will help prevent wear and tear, extend the lifespan, and keep the machine in excellent working condition.

Familiarizing yourself with the key components allows you to troubleshoot any issues quickly and carry out repairs when necessary. In this guide, we’ll cover the essential features that contribute to effective control and maneuverability of your lawn equipment.

Understanding the Lawn Tractor Control System

A well-functioning control system is vital for the safe operation and maneuverability of your lawn equipment. The smooth movement of the vehicle relies on a series of interconnected elements that work together to provide responsive handling and precision. Ensuring these components are in top condition is key to maintaining the machine’s overall performance.

Key Elements of the Control Mechanism

The primary mechanism responsible for guiding the machine consists of various interconnected pieces, each playing a role in ensuring that the operator has complete command over the direction of the vehicle. These elements must be properly aligned and maintained to prevent issues such as drifting or unresponsive turns. Regular checks and timely replacements can prevent costly repairs and downtime.

Impact of Proper Maintenance

Proper care of the system ensures smoother operation and longer-lasting functionality. Over time, wear and tear may affect the performance, leading to difficulties in controlling the machine. By performing routine maintenance and addressing minor issues promptly, the risk of more significant problems can be minimized, helping you to get the most out of your equipment.

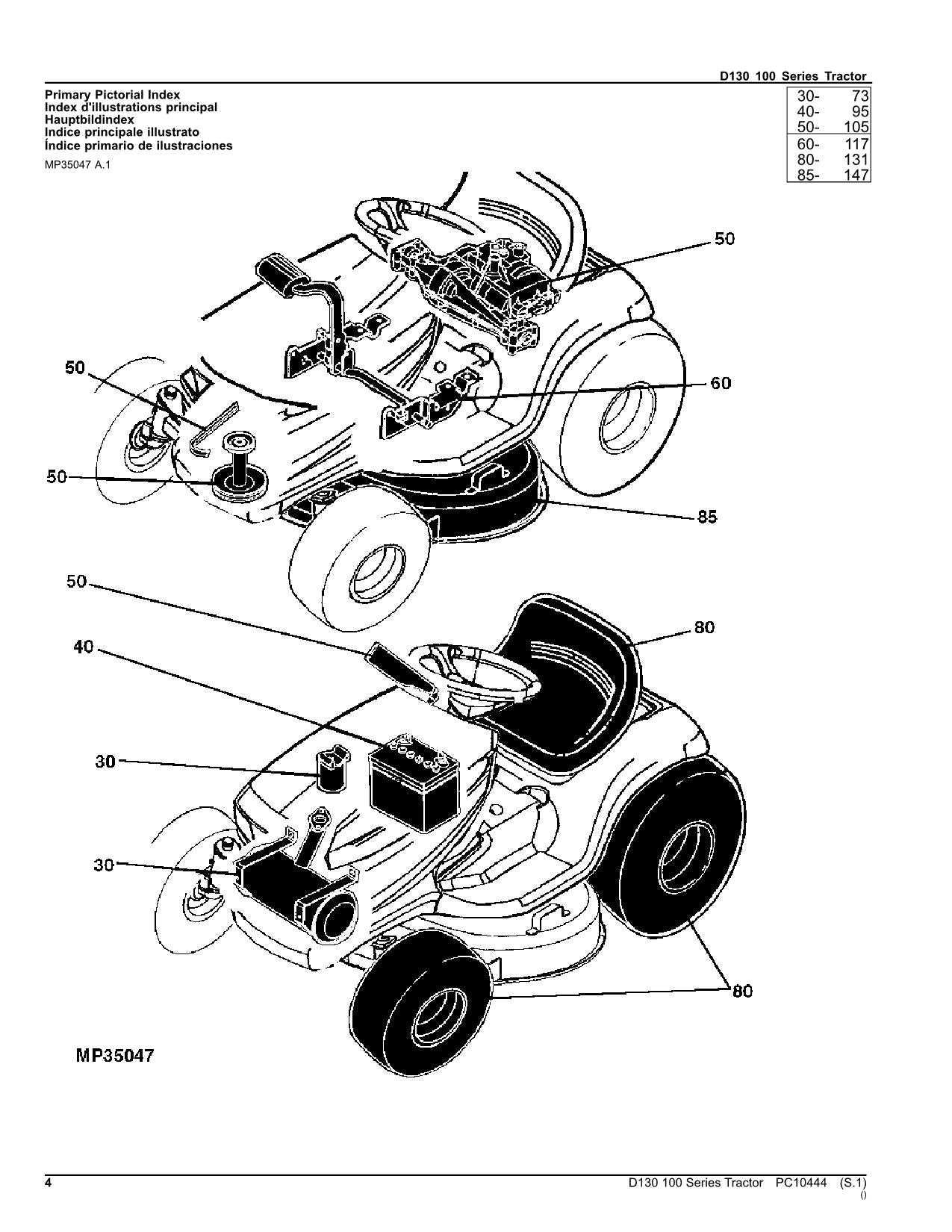

Key Components in the Control Assembly

Understanding the essential components involved in maneuvering your lawn machine is crucial for effective operation. Each part plays a specific role in providing the operator with the necessary control to guide the equipment with ease and precision. When all the elements function properly, the vehicle moves smoothly and responds promptly to user input.

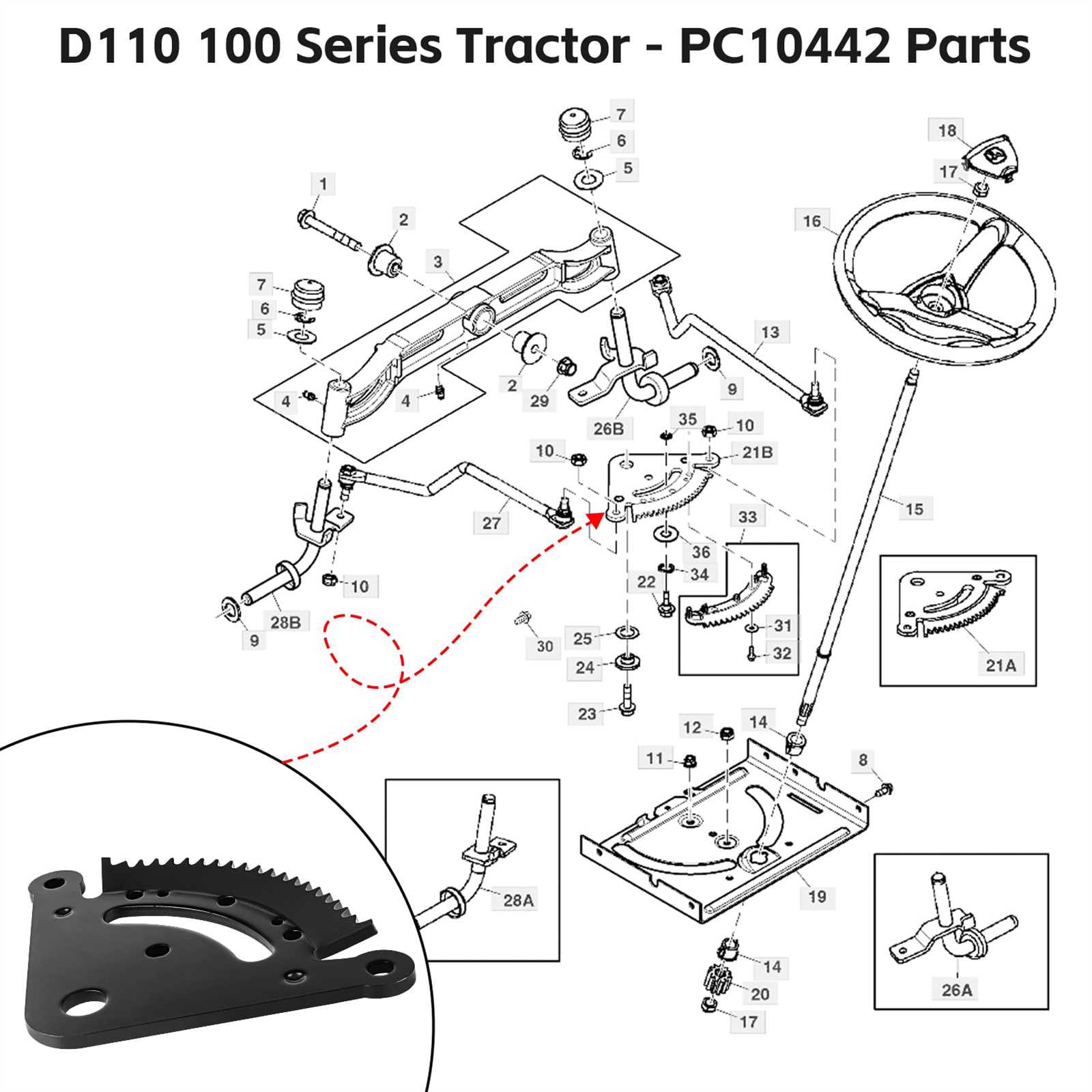

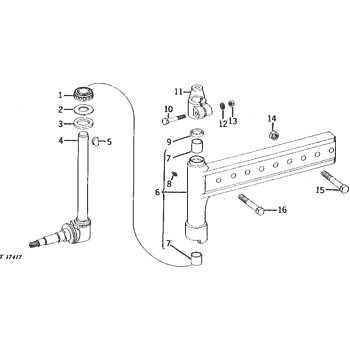

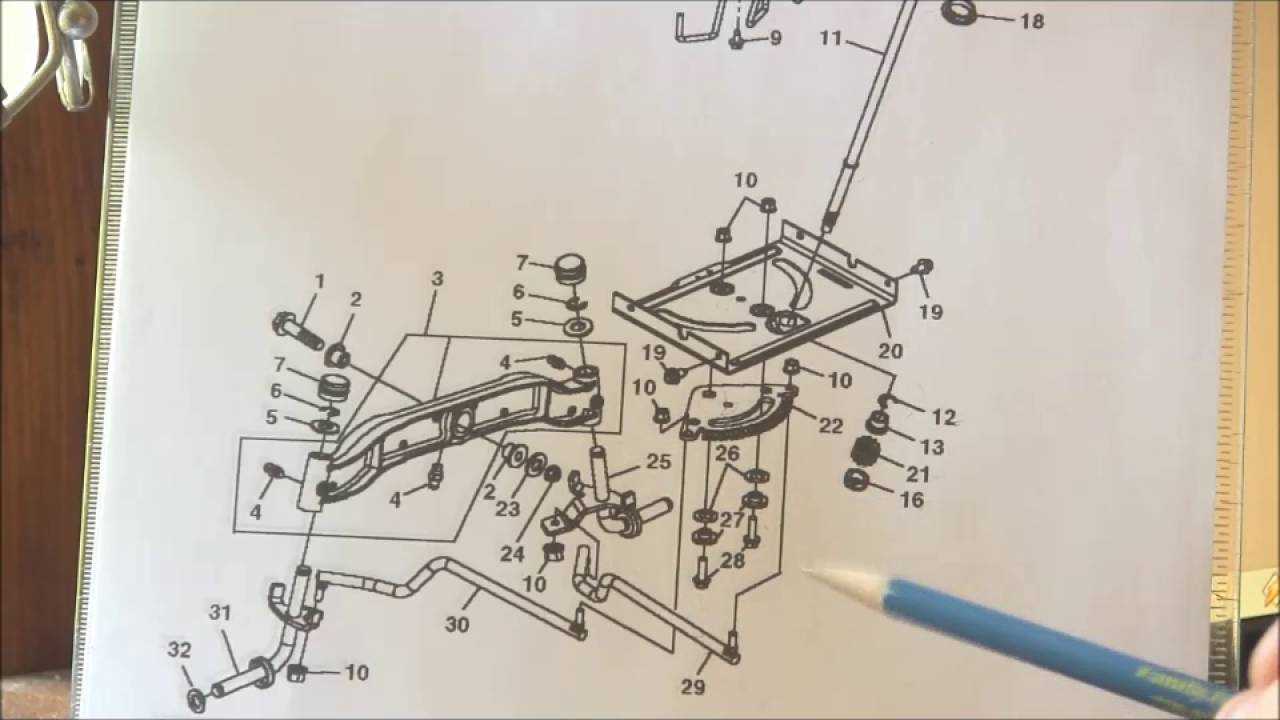

Crucial Mechanisms for Directional Control

The core mechanisms responsible for maintaining accurate direction consist of various elements such as rods, linkages, and pivot points. These pieces work together to translate the operator’s actions into movement. Ensuring these components are intact and correctly aligned is vital to avoid sluggish or unpredictable handling.

Importance of Regular Inspections

Regular checks of the individual components can help identify potential issues before they become severe. Wear and tear can take a toll on parts like the control column or connection joints. Timely replacement or lubrication can prolong the life of these elements and keep your machine running at its best.

How to Maintain Your Control Components

Proper maintenance is essential to keep your lawn machine running smoothly and to ensure long-lasting performance. The key to efficient operation lies in the condition of the components that control movement. Regular care can prevent wear, improve response time, and enhance overall reliability.

To maintain these crucial mechanisms, follow these steps:

- Inspect for wear: Regularly check all linkages, rods, and connections for signs of damage or looseness.

- Lubricate moving parts: Apply grease or oil to prevent friction, which can lead to premature wear.

- Check alignment: Ensure all components are properly aligned to avoid uneven operation or handling difficulties.

- Replace damaged parts: If any components are cracked or worn out, replace them promptly to prevent further damage.

- Tighten connections: Ensure bolts and fasteners are secure to avoid any instability in the system.

By following these simple steps, you can extend the lifespan of your control components and maintain optimal performance throughout the year.