For anyone looking to maintain or repair their firearm, understanding the layout of its components is essential. Having a clear reference to how each part fits together can save both time and effort during the repair process. A detailed visual guide is an invaluable tool, allowing users to pinpoint issues quickly and accurately.

Whether you’re a novice or an experienced enthusiast, knowing the specific roles of each component is crucial. This reference can help in identifying worn or broken parts and assist in sourcing replacements with confidence. A reliable diagram simplifies the process of reassembly and maintenance, ensuring that everything functions properly after repairs.

With a thorough understanding of the inner workings of the firearm, owners can troubleshoot problems more efficiently and avoid costly mistakes. A well-organized diagram not only shows the individual pieces but also demonstrates their interconnection, offering a holistic view of how everything works together.

Understanding Stevens Model 87D Components

Every firearm consists of various crucial elements that work together to ensure proper function. Familiarizing yourself with these components allows for more effective maintenance, troubleshooting, and repairs. Each piece, from the smallest spring to the largest receiver, plays an important role in the overall operation.

Key Elements of the Firearm

The core structure of the firearm includes several critical parts such as the trigger mechanism, the firing pin, and the safety system. These components interact to provide smooth operation when the weapon is used. Understanding how these elements fit into the overall design can help in identifying potential issues and guide you through repair procedures.

Assembly and Maintenance Considerations

Proper assembly is key to the longevity and functionality of the firearm. Knowing how each part fits into its respective place ensures that the firearm operates safely and efficiently. Regular maintenance of key components, such as cleaning and lubricating moving parts, is essential to prevent wear and tear that could lead to malfunctions.

How to Use the Parts Diagram Effectively

Using a visual reference to understand a firearm’s internal structure can make the process of repair and maintenance much easier. An accurate illustration helps users quickly identify the location and function of each individual element. By following the guide, users can efficiently locate problems and ensure all components are correctly assembled.

Identifying Components and Their Functions

The first step in using a schematic effectively is to familiarize yourself with the individual parts and their roles. Each component in the guide is usually labeled or numbered for easy identification. Understanding what each piece does within the system will help in diagnosing issues and selecting the correct replacement if needed.

Following the Assembly Process

When reassembling or troubleshooting, following the diagram in a logical order is crucial. A well-organized visual reference allows you to see how each element interacts with others, ensuring nothing is overlooked. By starting from one section and moving methodically through the rest, you can maintain accuracy and avoid unnecessary mistakes during the repair process.

Common Issues with Stevens Model 87D Parts

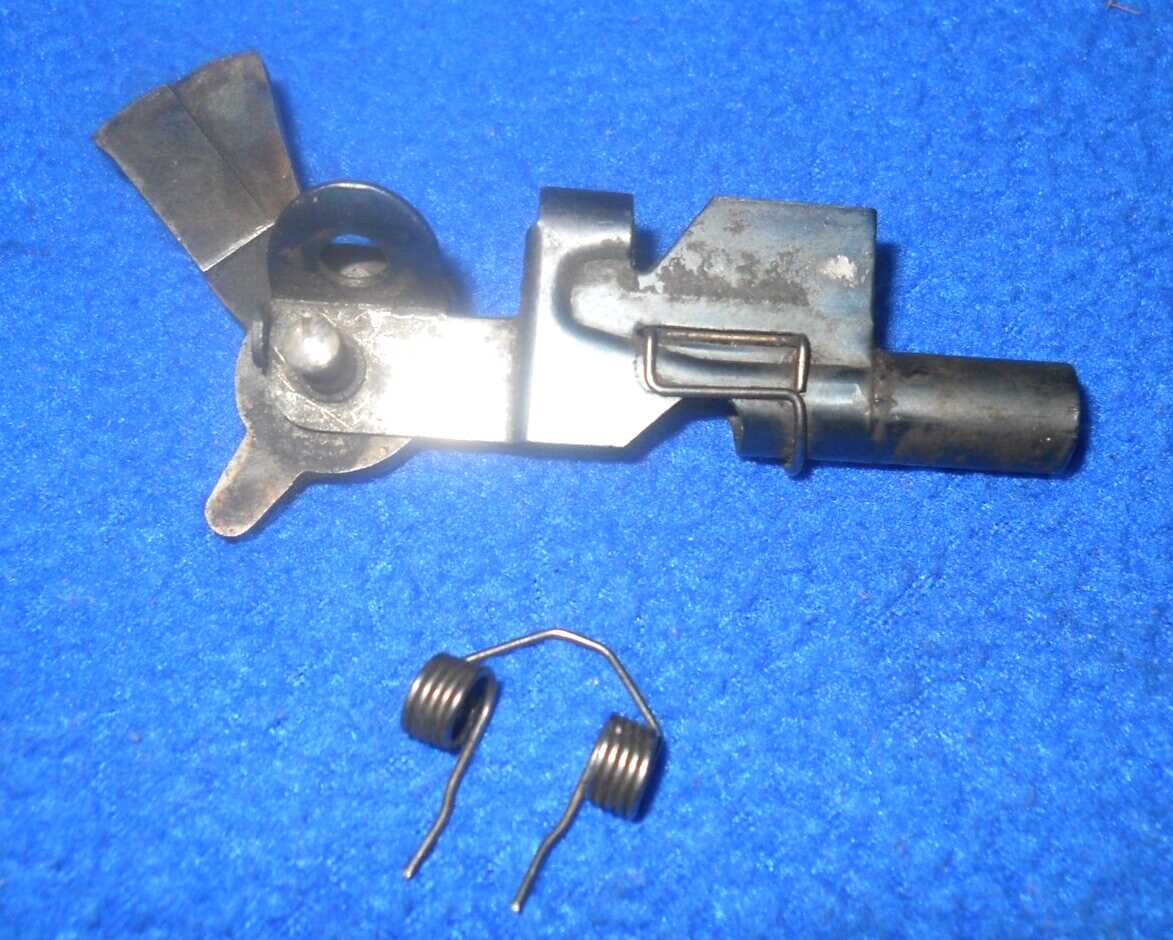

Like any mechanical system, firearms can experience a variety of issues over time due to wear and tear. Identifying these problems early is crucial for ensuring the firearm continues to function safely and effectively. Common issues often stem from misalignment, broken springs, or wear on moving parts that need attention.

Malfunctions Due to Worn Components

One of the most frequent problems occurs when key elements become worn from continuous use. This can result in failure to cycle properly, misfires, or difficulty in engaging the safety mechanism. Regular inspection of these components can help identify when they need to be replaced or serviced, preventing major malfunctions.

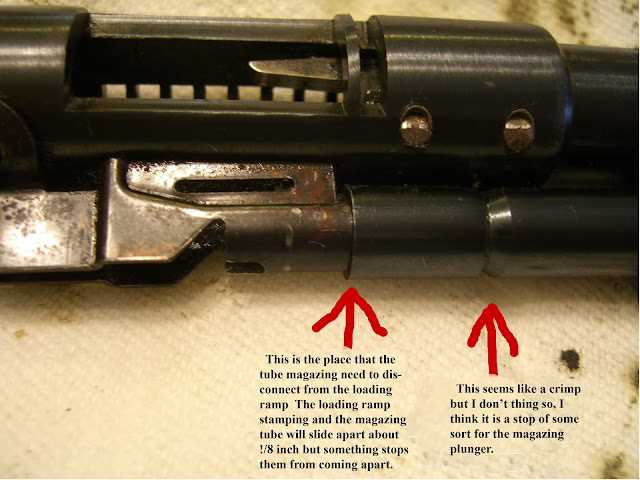

Assembly Issues and Misalignment

Improper assembly is another common issue, especially after disassembly for cleaning or repair. Incorrectly installed components can cause parts to function poorly or not interact as intended. Ensuring that each piece is placed in its correct position during reassembly is essential to avoid damage and ensure smooth operation.