When it comes to maintaining and repairing outdoor power equipment, understanding the internal components is essential. Knowing the layout of each part and how they work together can save time and effort, ensuring your machine runs smoothly for years. A detailed overview of the key elements in the system helps users identify potential issues before they become major problems.

By referring to visual representations and breakdowns of each component, operators can easily locate parts that may need replacement or adjustment. This knowledge also enhances troubleshooting skills, providing clarity on how each section functions within the larger mechanism.

Regular maintenance is crucial for extending the lifespan of your machine, and a clear understanding of its components is the first step towards efficient care. Whether you are looking to replace worn-out components or perform routine checks, this guide will give you the information needed to keep your equipment in optimal condition.

Understanding the 455 Rancher Parts

Knowing the key components of any machinery is fundamental for proper operation and maintenance. Each part plays a specific role, working together to ensure efficient performance. Whether you’re performing regular maintenance or troubleshooting, understanding the configuration and function of each element will help you take better care of your equipment.

Key Components and Their Functions

The main parts of the system include the engine, fuel system, drive mechanism, and safety features. The engine is the heart of the machine, providing the power needed for its operation. The fuel system is essential for proper combustion, while the drive mechanism ensures movement and performance. Safety features, such as brakes and switches, protect both the user and the machine from potential hazards.

How Each Element Contributes to Performance

Each individual component, from the smallest screw to the larger assemblies, contributes to the overall effectiveness of the system. For example, the ignition system is responsible for starting the engine, while the air filter keeps debris out, ensuring smooth operation. A malfunction in any of these parts can impact performance, making it crucial to understand their interconnectivity.

Regular inspection and timely replacement of worn-out elements will keep the machine in peak condition. Maintaining a thorough understanding of each part will also help you identify issues early and prevent costly repairs.

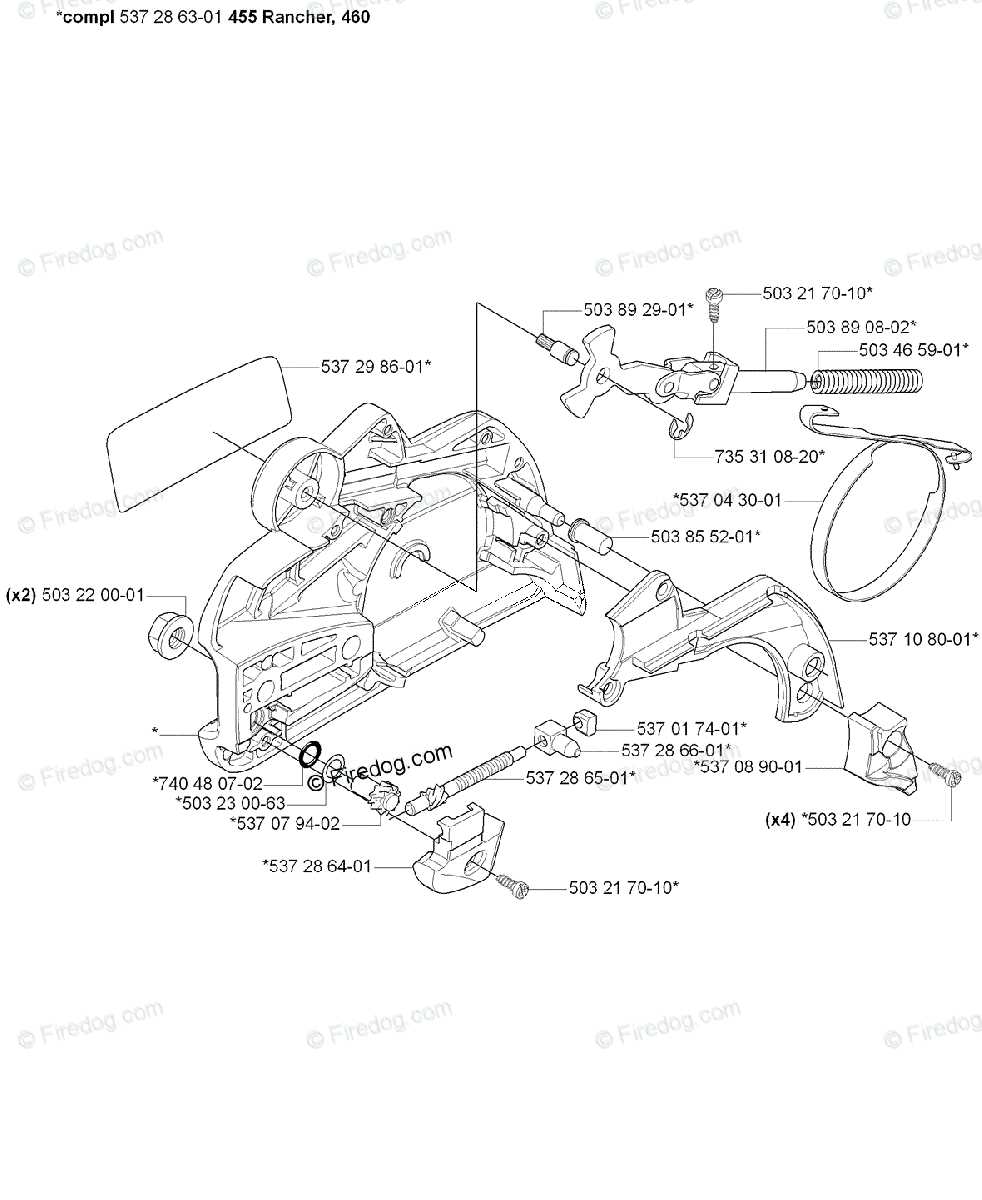

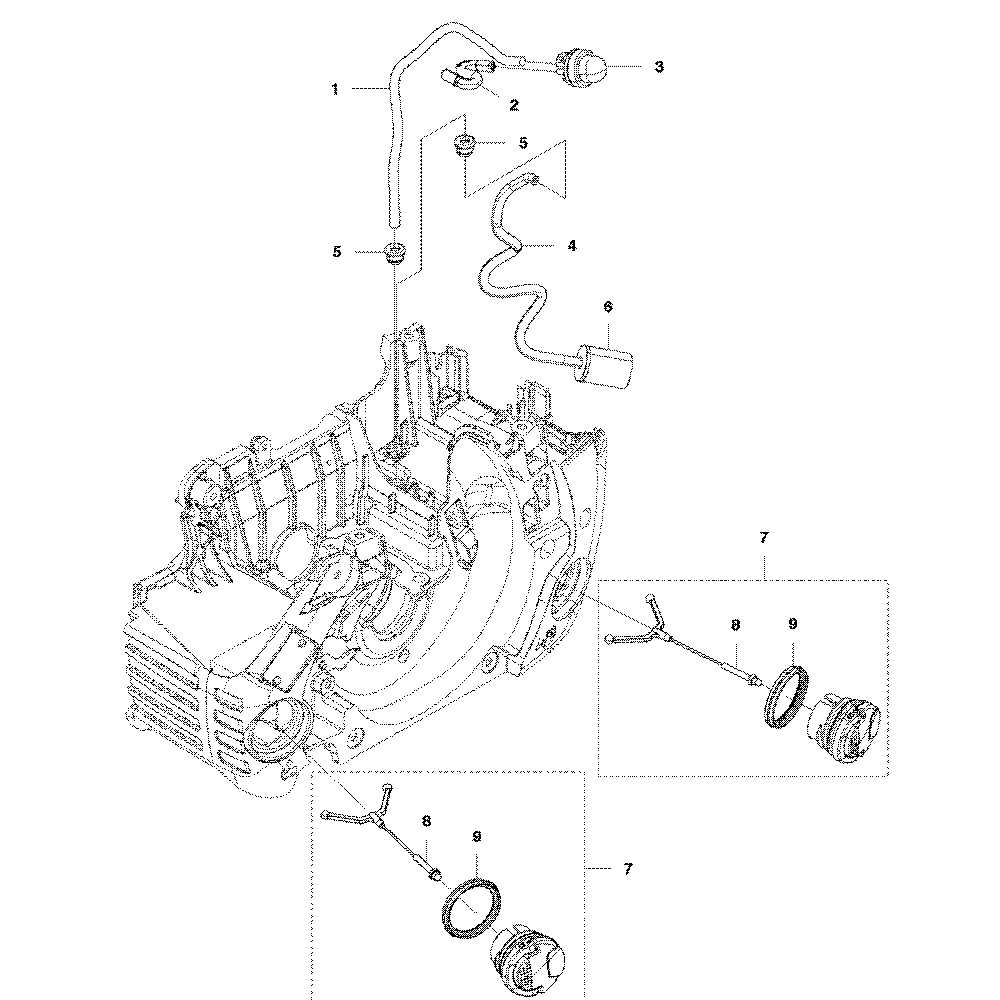

How to Read a Parts Diagram

Understanding visual representations of mechanical components is essential for effective repairs and maintenance. A detailed illustration of the internal structure helps users identify individual elements and their connections within the system. Mastering how to interpret these visuals enables you to pinpoint specific parts and understand their functions in the larger mechanism.

Identifying Each Component

When looking at an exploded view, each part is typically labeled with a number or code. These identifiers correspond to a reference list, making it easier to locate specific items in the manual or order replacements. The layout of these diagrams often shows how parts are assembled and their relationships to other elements in the machine.

Understanding Connections and Functions

Diagrams also illustrate how parts fit together and interact. Arrows, lines, and symbols are commonly used to represent connections between components, such as bolts or wiring. Familiarizing yourself with these symbols will help you understand how various elements work in unison and guide you in troubleshooting or reassembly tasks.

By regularly consulting these visuals, you can confidently identify malfunctioning parts and ensure accurate replacements, leading to more efficient maintenance and longer-lasting equipment performance.

Common 455 Rancher Parts Issues

Over time, wear and tear on mechanical systems can lead to common issues that affect the overall performance. Identifying these problems early on can prevent more serious damage and costly repairs. Understanding the most frequent concerns with the various components allows users to troubleshoot effectively and perform timely maintenance.

Fuel System and Ignition Problems

The fuel system is often a source of frustration, with clogged filters or fuel lines causing issues with starting or efficiency. Additionally, the ignition system may experience failures, such as faulty spark plugs or ignition coils, which can prevent the engine from firing properly. Regular inspection and cleaning of these components are essential for smooth operation.

Wear and Tear on Drive Mechanism

The drive mechanism, including the chain and sprockets, is another common area for problems. Overuse can lead to premature wear, which may result in decreased performance or even failure to engage. Regularly checking and replacing these parts ensures that the machine functions properly, providing the necessary power for its tasks.

Maintaining awareness of these issues and addressing them as they arise will extend the life of the equipment, ensuring consistent and reliable performance over time.