For efficient maintenance and repairs, it’s essential to understand the layout and functionality of each element in your tool. Proper identification and handling of individual parts ensure optimal performance and longevity of the machine. Familiarity with the internal mechanisms allows for quicker troubleshooting and accurate replacements when necessary.

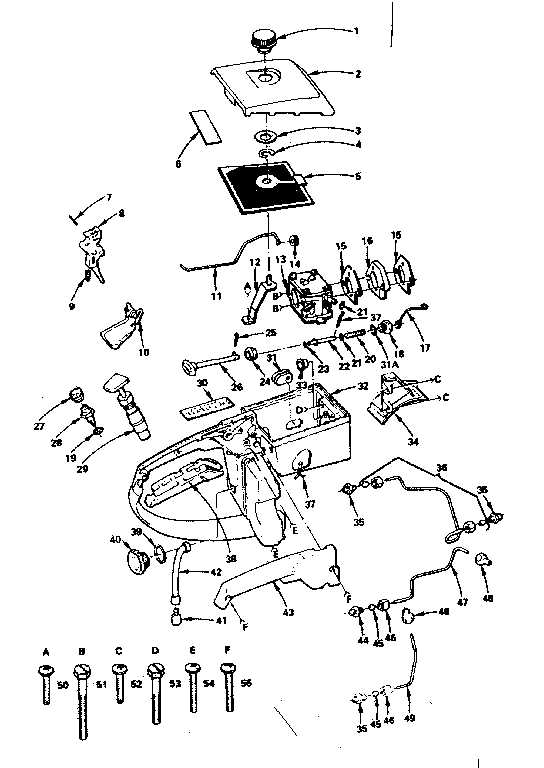

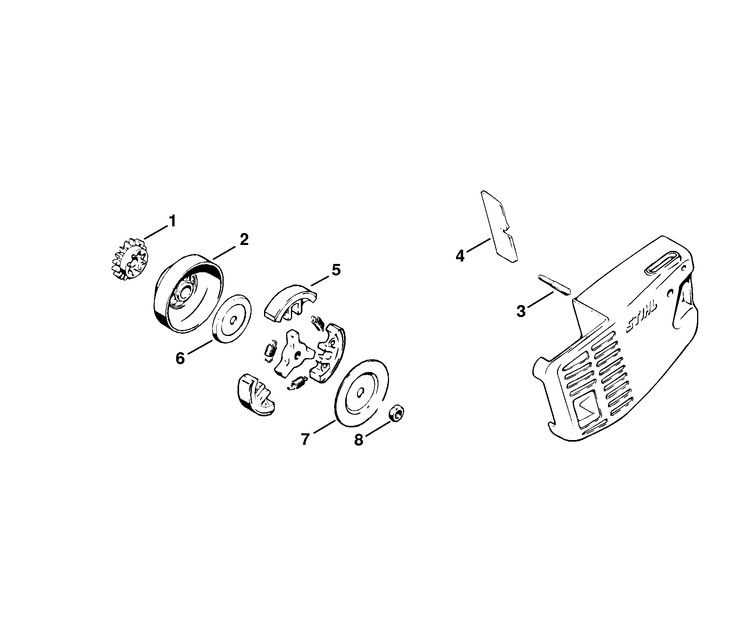

Detailed schematics provide a visual guide to help you easily identify each part and its placement. By referring to these illustrations, you can confidently assess wear and tear, ensuring you replace or repair only what is needed. Whether you’re a seasoned professional or a beginner, having a clear understanding of the components enhances your ability to manage repairs and upkeep.

Investing time in learning about the various sections of your equipment is a valuable step toward maintaining its efficiency and extending its service life.

Stihl 041 Parts Overview

Understanding the different components of your machine is crucial for maintaining its efficiency and durability. Each section plays a specific role in ensuring smooth operation, and knowing their functions helps with troubleshooting and repairs. The overall structure is designed to keep the system working at its best, and recognizing how each element contributes to this balance is key for proper upkeep.

Core Elements of the Mechanism

The core elements of the machine include the engine housing, power transmission system, and the control units. These essential components work together to convert fuel into motion, providing the necessary energy for operation. Regular inspection of these parts ensures that your device remains reliable and performs optimally under various conditions.

Auxiliary Components and Accessories

In addition to the primary elements, several auxiliary parts help with functionality and convenience. These include filters, levers, and fasteners that are designed to enhance safety and efficiency. Understanding the role of these accessories allows for easier identification and timely replacement when signs of wear appear.

Identifying Key Components of Stihl 041

Proper identification of the main sections in your tool is crucial for effective maintenance and repair. Knowing each part’s role helps ensure smooth performance and prevents unnecessary damage. Clear understanding of these elements allows you to address specific issues quickly, saving both time and resources.

Engine and Power System

The engine and its power system are the heart of the tool, converting energy to mechanical motion. Components like the ignition system, fuel delivery, and exhaust system work together to produce consistent power. Regularly checking these elements for any signs of wear or malfunction can prevent more significant issues down the line.

Control Mechanisms and Safety Features

Control mechanisms, including switches, levers, and safety features, ensure safe and reliable operation. These parts allow users to operate the tool efficiently while minimizing risks. Keeping these components in good condition guarantees both performance and safety during use.

How to Replace Stihl 041 Parts

Replacing worn or damaged components is essential to maintaining the functionality of your equipment. Knowing the proper steps and having the correct tools ensures that each part is replaced correctly, avoiding further damage and ensuring peak performance. This process can be done efficiently with some basic knowledge and preparation.

Preparation and Safety

Before beginning any replacement, it’s vital to ensure the tool is powered off and disconnected from any power sources. Make sure to wear appropriate safety gear to prevent accidents. Having the right replacement components on hand and organizing your workspace will help streamline the process.

Step-by-Step Replacement Process

Start by carefully removing the damaged part using the correct tools. For example, screws or fasteners may need to be unscrewed to access internal components. Once the part is removed, replace it with a new one and secure it properly. Be sure to follow the manufacturer’s guidelines for each specific component to avoid errors during installation.