Maintaining a vehicle’s stopping system is crucial for safety and performance. Having a clear understanding of its components can make the maintenance process smoother and more effective. Whether you are a mechanic or an owner, knowing how each part functions and interacts ensures that the system works as intended.

Identifying and troubleshooting the system’s components can help prevent issues before they cause damage. Understanding the layout and functionality of each element allows for quicker repairs and optimizes the overall performance. With the right knowledge, you can ensure the vehicle’s stopping ability is always reliable.

When it comes time for replacements, recognizing the correct parts and their placement is essential for a seamless installation. Efficient identification of components not only saves time but also ensures that the correct replacements are used for optimal functionality and safety.

Understanding Key Components of Vehicle Stopping Systems

Effective maintenance of a vehicle’s stopping mechanism requires knowledge of the essential components that work together to ensure reliable performance. These elements must function seamlessly to provide safe and efficient operation. Knowing how each part contributes to the system can help in diagnosing issues and making precise repairs.

Each individual component plays a critical role, from generating the necessary force to slowing down or halting the vehicle to the mechanical interactions that make this process possible. Understanding their roles helps identify any discrepancies in performance, making troubleshooting more straightforward.

Proper familiarity with the system’s design is key for anyone responsible for its upkeep. With a clear understanding, one can confidently manage maintenance tasks, ensuring the vehicle remains in optimal condition while extending the life of the system itself.

Identifying Common Issues with Stopping System Components

Recognizing the signs of malfunction in a vehicle’s stopping system is essential for timely maintenance and repair. Over time, components can wear out or become damaged, leading to decreased performance and potential safety risks. Knowing the common issues that arise helps in quickly addressing them before they cause further complications.

Some of the most frequent problems include insufficient friction, which results in longer stopping distances, and misalignment, which can cause uneven wear and irregular performance. Detecting these issues early can prevent unnecessary damage to other related components.

Regular inspection and proper understanding of the system’s components make it easier to pinpoint when something is amiss. By staying alert to unusual behavior or irregularities, you can maintain the vehicle’s stopping ability at optimal levels.

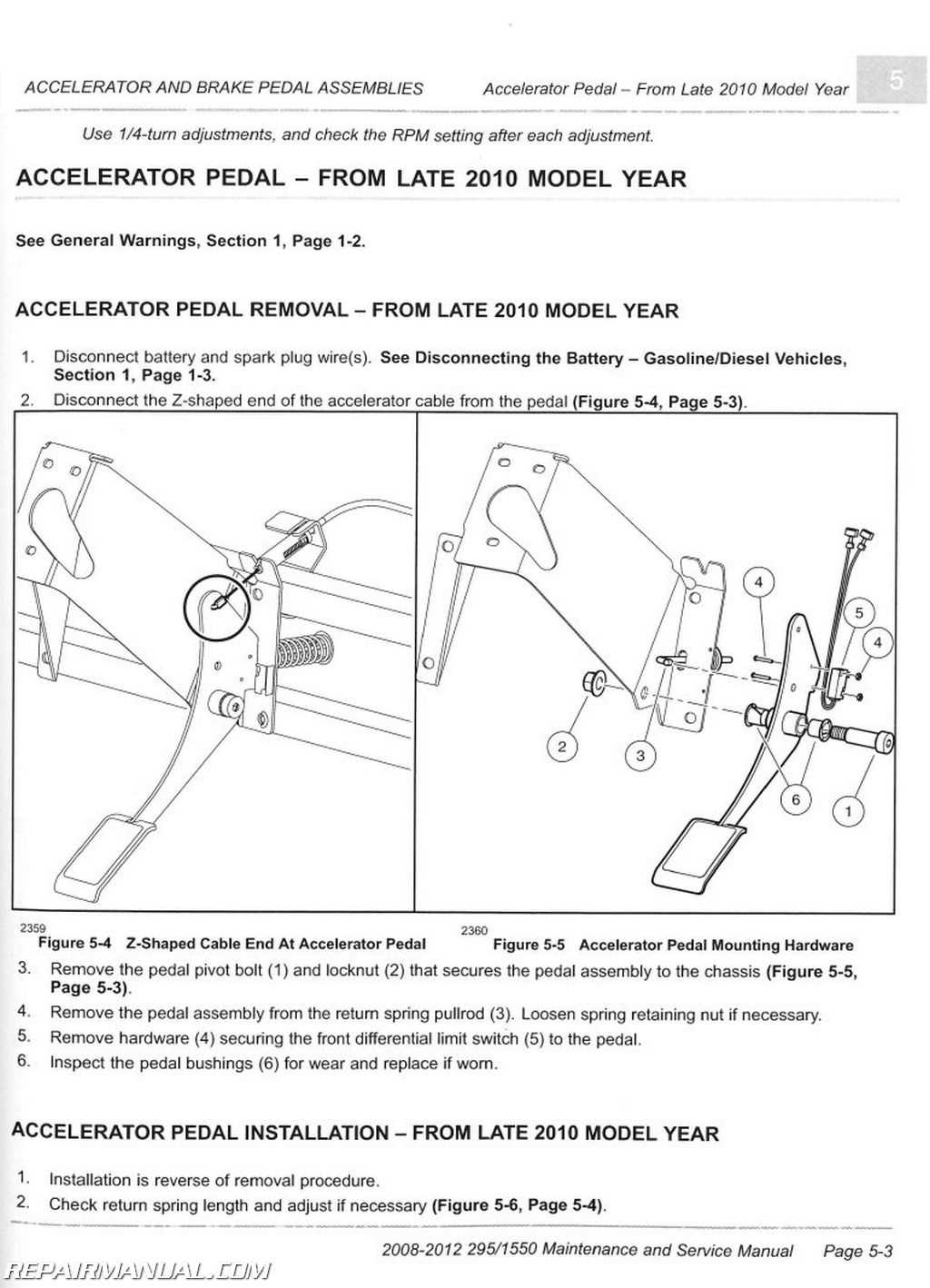

How to Replace Vehicle Stopping System Components

Replacing worn or damaged elements of the stopping mechanism is an important task that ensures the continued safety and performance of the vehicle. Proper replacement not only restores the system’s functionality but also helps prevent further damage to connected components. This process involves understanding the components involved and knowing the right steps to take for effective replacement.

First, it is essential to gather the necessary tools and replacement items, including the correct components and safety equipment. Once you have the right parts, ensure the vehicle is securely positioned and all power sources are disconnected to prevent accidents during the replacement process.

Next, carefully remove the worn components by following the system’s layout. Replace them with the new pieces, ensuring they are properly aligned and securely fastened. Finally, test the system to verify that all components are working correctly and the vehicle is functioning as intended.