Proper maintenance and understanding of your equipment’s inner workings are essential for its long-lasting performance. Having a clear overview of the various components and their functions can greatly enhance your ability to perform repairs or replacements when needed.

Identifying the right parts and knowing how they fit together is crucial for ensuring the smooth operation of your chainsaw. Understanding the structure of the tool not only helps with routine upkeep but also with troubleshooting any issues that may arise during usage.

In this guide, we will walk you through the key elements of a typical chainsaw and how they interact. We will also provide insights into how to address common problems and ensure optimal functioning through effective repairs and part replacements.

Understanding the Chainsaw Components

Every tool is composed of several crucial elements that work in tandem to ensure efficient operation. When you take the time to learn about each component’s role, you can better maintain and troubleshoot your equipment. The complexity of these components is what makes the tool effective, and understanding them can prevent unnecessary repairs and extend the tool’s lifespan.

Key Components and Their Functions

At the heart of the chainsaw, you’ll find a set of interrelated mechanisms that power the machine. Each part, from the engine to the cutting system, plays a specific role in making the tool functional. Understanding how these components interact ensures you can recognize when something is wrong and act quickly to resolve the issue.

Maintenance and Troubleshooting Tips

Regular maintenance is the key to keeping your tool in top condition. Knowing which components need the most attention and what signs to look for when something goes wrong can save you time and money. Whether it’s replacing worn-out parts or fine-tuning the system, understanding the setup allows for efficient upkeep and repairs.

How to Read the Assembly Breakdown

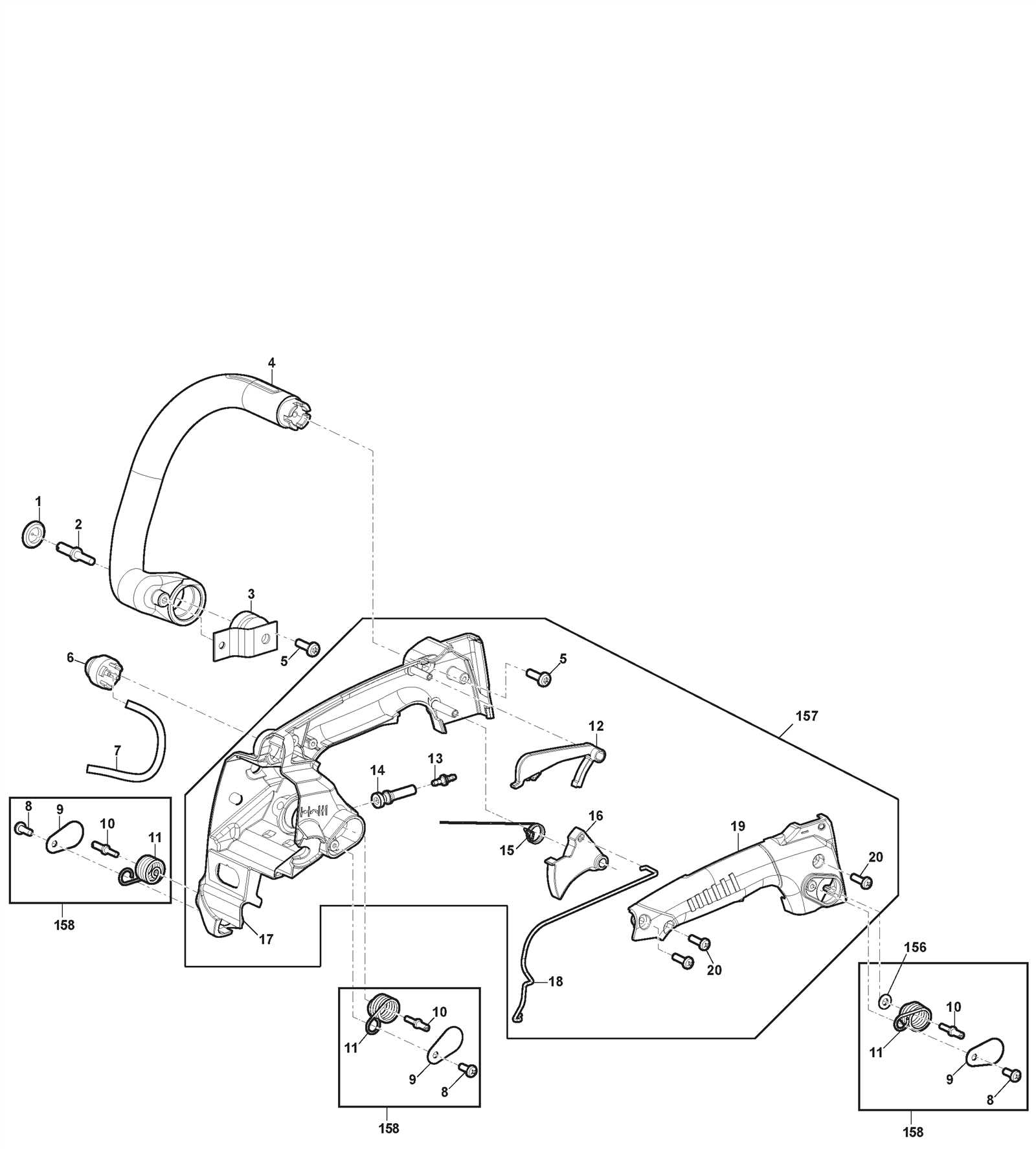

Understanding the breakdown of a tool’s assembly is essential for effective maintenance and repair. Visual representations of the components allow you to see the relationships between each part and how they come together to form a functioning unit. By familiarizing yourself with these images, you can more easily identify which part needs attention or replacement.

Each part is typically labeled with a number or code that corresponds to a list, making it easy to reference specific components. Pay close attention to the layout, as it will highlight how parts fit together, their orientation, and their position within the whole system. This detailed view helps you visualize what is inside the machine and prepares you for any necessary fixes.

Common Issues and Replacement Parts

Over time, tools can experience wear and tear, leading to a variety of common issues that may affect their performance. Understanding these typical problems helps you address them promptly, ensuring the tool remains functional and efficient. Recognizing the need for replacements is key to maintaining the overall integrity of your equipment.

Frequent issues include problems with the ignition system, fuel lines, and the cutting mechanism. These components are often subjected to heavy use and can degrade over time. For example, a worn-out spark plug or a clogged fuel filter can prevent the tool from starting or operating efficiently.

Replacement components should be chosen carefully based on quality and compatibility. It is important to select the right parts to restore the tool to its optimal condition. Keeping a set of commonly needed replacements, such as filters, spark plugs, and drive belts, can reduce downtime and extend the life of your tool.