When dealing with complex equipment, understanding its structure and how each element fits together is essential for efficient maintenance and troubleshooting. A visual representation of the internal parts can significantly aid in grasping the relationship between different components and their functions. By analyzing such visuals, users can quickly identify where issues may arise and how to resolve them.

For those working with machinery, recognizing the specific role of each piece and knowing its exact placement is crucial. A detailed overview helps users navigate through the system with ease, ensuring repairs and adjustments are carried out accurately. Familiarity with these details can enhance performance, prevent breakdowns, and extend the lifespan of the equipment.

In this guide, we will explore the structure of these systems and provide valuable insights into how each section contributes to the overall functionality. Whether you’re a professional or an enthusiast, having a clear understanding of these components is the first step towards mastering the device’s full potential.

Understanding MS361 Parts and Functions

To effectively use and maintain any machine, it is crucial to understand the different elements that make up its structure and their respective roles. Knowing how each component contributes to the overall system helps in identifying potential issues and performing maintenance tasks efficiently. In this section, we will break down the key components, explaining their purpose and how they interact to ensure smooth operation.

Key Elements and Their Roles

Each component plays a specific role, either contributing to power transmission, movement, or safety. Below are some of the critical parts you will encounter:

- Engine Components: These parts generate the power necessary for the machine to function. Key elements include the fuel system, spark plug, and exhaust system.

- Drive Mechanism: This system transfers power from the engine to the moving parts. It includes gears, belts, and other components that ensure proper movement.

- Safety Features: Safety components like the trigger and brake system are essential for user protection and controlling the machine’s operation.

How Components Work Together

The different parts must work in harmony for optimal performance. Here’s a basic overview of their interaction:

- The engine generates power, which is transmitted through the drive mechanism to the moving elements.

- The safety system ensures that the device operates within safe parameters, preventing accidents or damage.

- Maintenance of these parts ensures long-term functionality and reduces the likelihood of malfunction or wear.

By understanding how these elements function and connect, users can make more informed decisions regarding repairs, replacements, and overall upkeep.

How to Read the MS361 Diagram

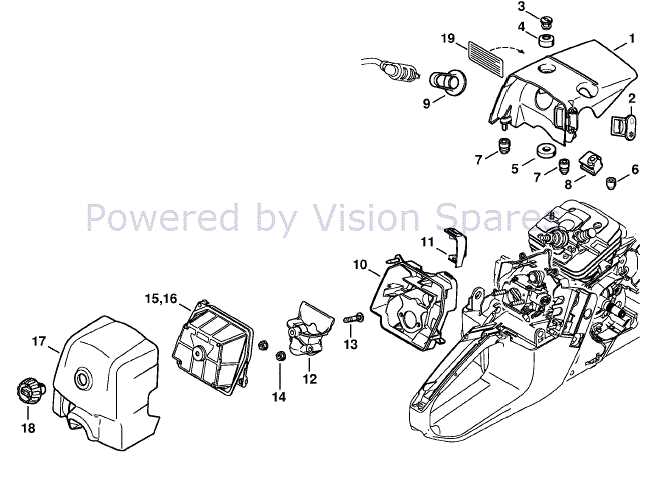

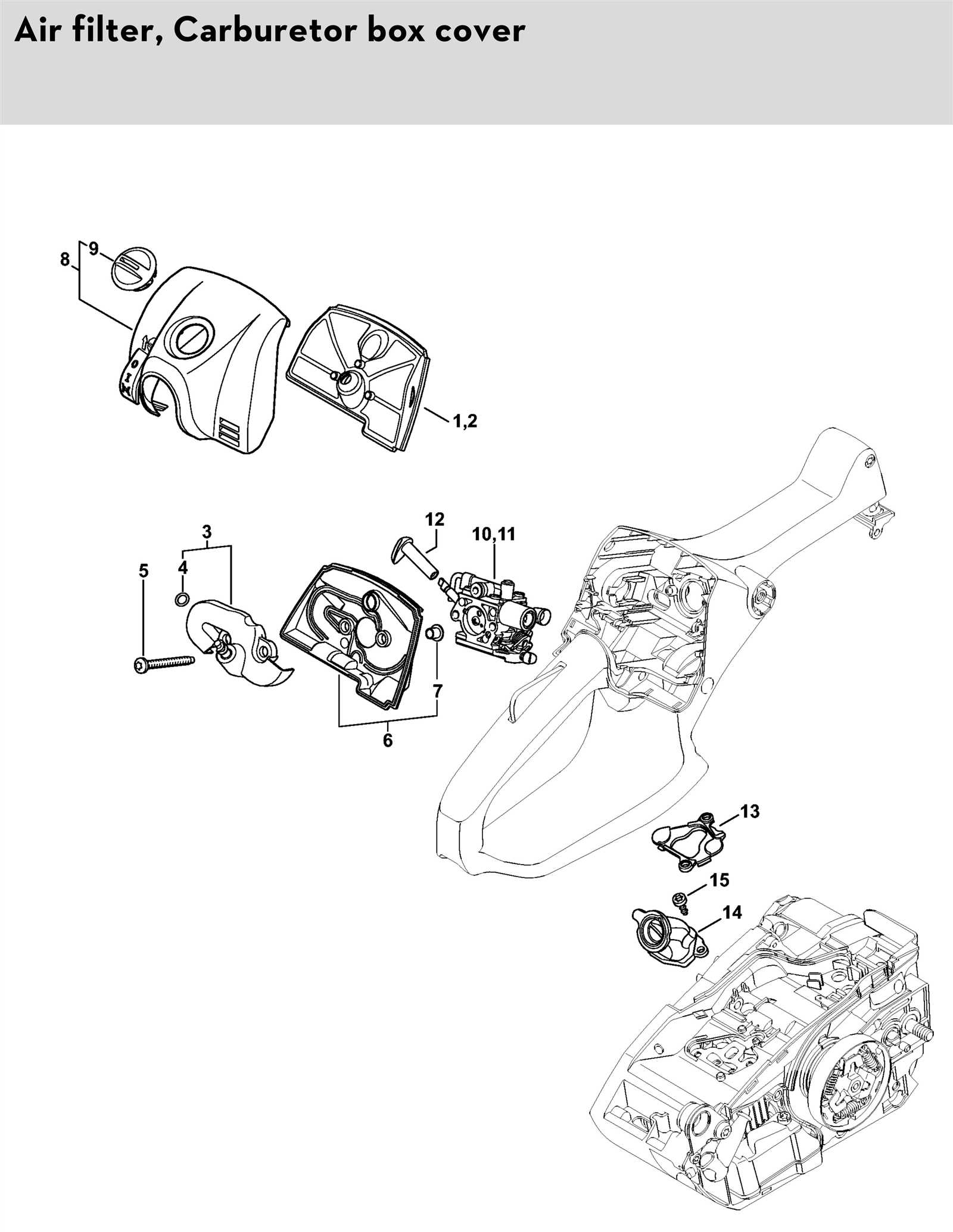

Interpreting a visual representation of a machine’s structure can significantly simplify the process of understanding its internal configuration. By analyzing these layouts, users can identify the position and function of each element, making maintenance and troubleshooting much easier. This section will guide you through the steps of reading such a visual, helping you understand how the different components fit together.

The key to reading this layout effectively is focusing on the labels and connections between elements. Each part is typically represented with a number or identifier, often corresponding to a detailed description or part list. Understanding how these components are interconnected helps users follow the flow of energy or material, aiding in the diagnosis of issues and ensuring proper assembly.

Follow the outlined sections to identify the key components and their placements, which will allow you to troubleshoot more efficiently, recognize wear or damage, and perform timely repairs.

Common Issues with MS361 Components

Like any machine, certain elements may experience wear or malfunction over time. Recognizing common issues within the system can prevent further damage and reduce downtime. This section highlights frequent problems that users may encounter and offers advice on how to address them efficiently.

One of the most common issues involves the engine not starting or losing power. This can be caused by fuel system problems, such as clogged fuel lines or a dirty filter. Another frequent problem is the improper functioning of the drive mechanism, which can lead to inconsistent movement or reduced performance. Issues with safety features, like malfunctioning triggers or brakes, can also occur, often due to wear or contamination.

By understanding these potential issues and how they affect the machine, users can perform basic checks and maintenance to ensure everything functions as it should. Timely identification of these problems helps extend the life of the equipment and maintain optimal performance.