Understanding the structure and individual components of an engine is crucial for efficient performance and longevity. When working with small engine models, knowing how each part interacts ensures smoother operations and helps troubleshoot issues quickly.

In this guide, we will explore the various elements that make up the engine system, focusing on key components essential for its function. Whether you’re performing routine maintenance or addressing specific repairs, this information will aid in identifying and understanding each part’s role.

Maintenance is key to keeping engines in optimal condition. By regularly checking and replacing components, you can prevent costly repairs and extend the engine’s life. Understanding the internal layout and function of each element allows for informed decision-making during service or upgrades.

Engine Overview

The engine is a vital part of many outdoor and industrial machines, driving their power and functionality. With its robust design and reliable performance, this engine model stands out for its durability and versatility. Understanding its essential features helps users maintain its peak efficiency and ensure a longer service life.

Key Features

This engine is known for its solid construction and impressive power output. Its compact size makes it ideal for various applications, while its high-efficiency system allows for excellent fuel economy. The design ensures that users can operate it with ease while minimizing the need for frequent repairs or parts replacement.

Functionality and Efficiency

Equipped with advanced technology, the engine optimizes performance in demanding conditions. From heavy-duty tasks to more routine operations, it is designed to provide consistent results with minimal maintenance. Understanding the engine’s core components and how they work together ensures that users can troubleshoot effectively and maintain its reliability over time.

Understanding Key Components of the Engine

Every engine consists of a variety of interconnected components that work together to deliver power and ensure smooth operation. A solid understanding of these essential parts allows for proper maintenance and troubleshooting, ultimately extending the engine’s lifespan and improving its efficiency.

Core Components

Among the critical elements of an engine are those that contribute to its performance and functionality. These include:

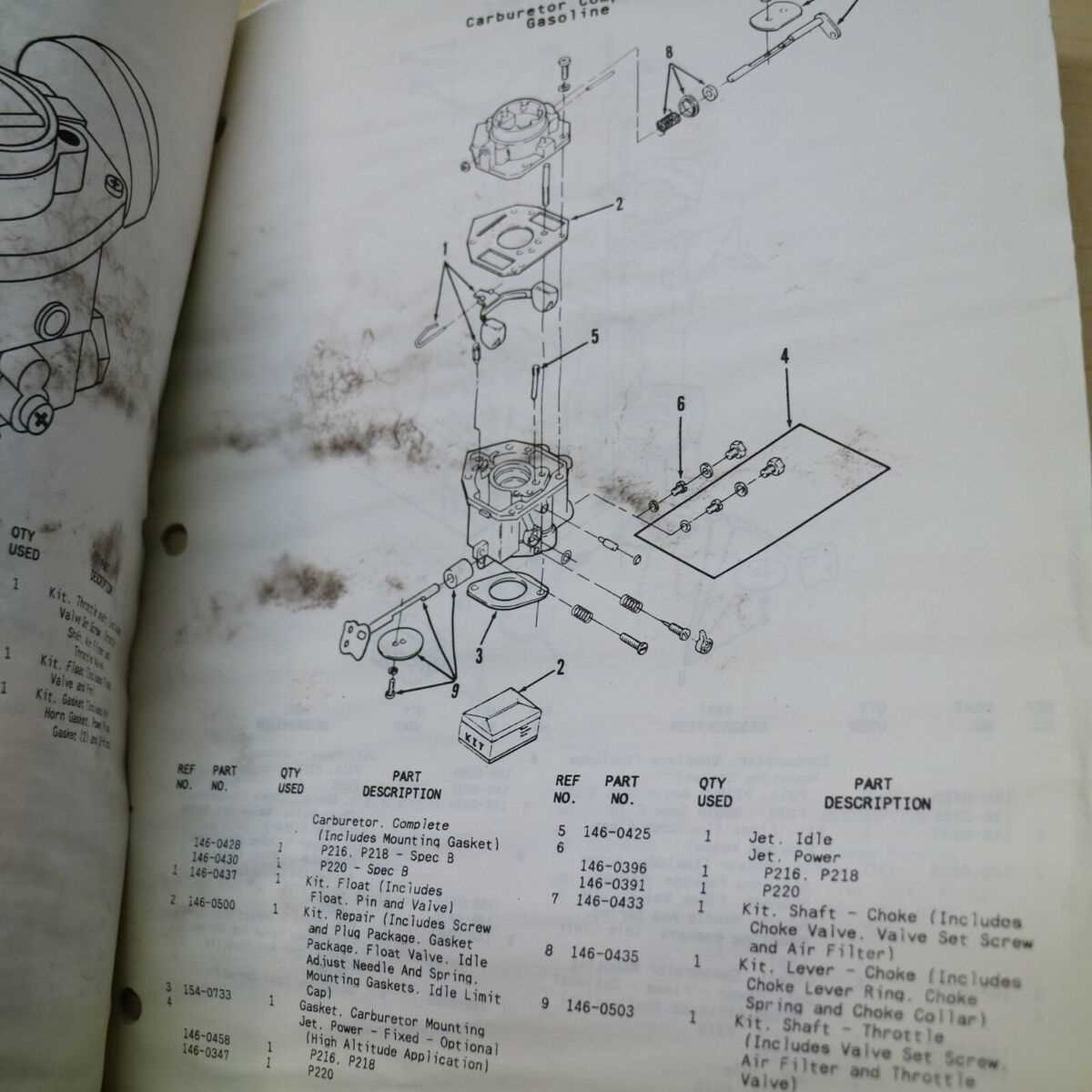

- Fuel System: Responsible for delivering the fuel to the engine for combustion.

- Ignition System: Ensures the engine starts and operates by igniting the fuel mixture.

- Cooling System: Keeps the engine from overheating during operation, ensuring consistent performance.

- Lubrication System: Reduces friction between moving parts, helping to prevent wear and tear.

Additional Critical Parts

Other important components include:

- Crankshaft: Converts the linear motion of the pistons into rotational motion to drive the machinery.

- Timing Belt: Ensures the synchronized operation of the valves and pistons.

- Air Filter: Keeps contaminants out of the engine, maintaining clean airflow for combustion.

Each of these parts plays a vital role in maintaining the efficiency and longevity of the engine, and understanding them is crucial for successful maintenance and operation.

Maintenance Tips for Engine Components

Proper upkeep of engine components is essential for maintaining efficiency and preventing costly repairs. Regular maintenance ensures that all parts function as intended, prolonging the engine’s lifespan and reducing the likelihood of unexpected breakdowns.

One of the most important practices is regular inspection of the key elements. Checking for wear and tear, fluid levels, and potential blockages can help identify small issues before they escalate. Routine cleaning is also crucial, particularly for the air filter, cooling system, and fuel lines.

It is also important to replace components at the right time. Parts such as spark plugs, filters, and belts can degrade over time and need replacing to maintain optimal performance. Using high-quality replacement parts ensures that the engine continues to operate smoothly.

Finally, lubrication is key to reducing friction between moving parts, preventing overheating and excessive wear. Ensuring the engine is properly lubricated and changing the oil regularly is a critical step in keeping the engine in top condition.