Maintaining and repairing outdoor power tools requires a clear understanding of their internal structure. A well-organized illustration of the key elements can significantly aid in identifying and resolving issues with your equipment.

By exploring the breakdown of individual sections and their relationship, you gain valuable insights into the proper handling and repair of your tool. This knowledge helps ensure optimal performance and longevity, minimizing downtime during maintenance tasks.

Using a visual guide allows for easier identification of worn-out or damaged components. Whether performing routine upkeep or troubleshooting malfunctions, having a clear reference enhances the accuracy and efficiency of your work.

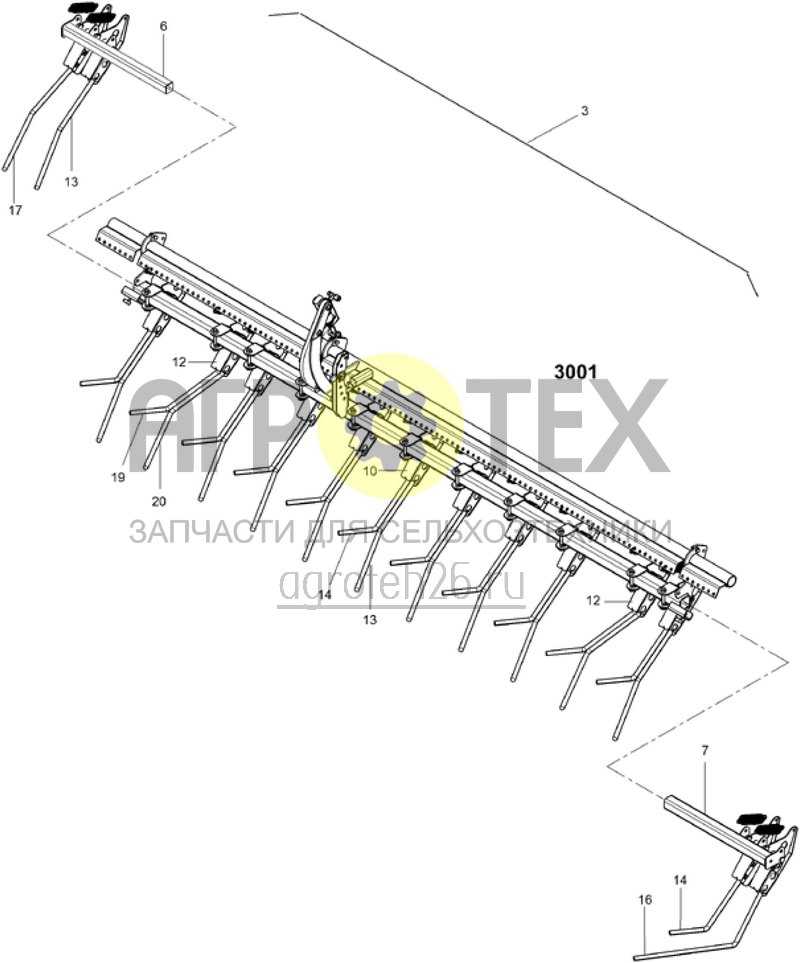

Understanding the Tool Assembly Layout

Proper knowledge of the tool’s internal configuration is essential for effective maintenance and repair. A clear representation of its individual sections provides a comprehensive view of how different components interact, ensuring smooth operation.

Each element within the assembly serves a specific function, contributing to the overall efficiency and performance. Recognizing the layout allows you to identify which parts require attention and which remain functional. It is crucial for pinpointing potential issues, whether from wear or malfunction.

Comprehending this layout equips you with the ability to tackle repairs with confidence. By understanding the placement and relationship of key elements, you can proceed with disassembly or reassembly without the risk of damaging any crucial parts. A detailed guide makes these tasks less intimidating and more manageable.

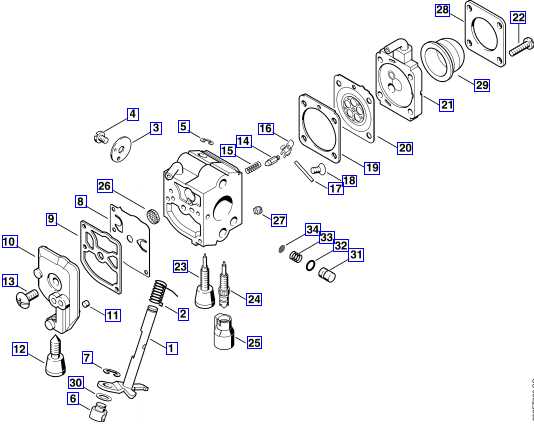

Identifying Key Components for Repairs

Understanding the crucial elements of your tool is vital for effective maintenance. Recognizing which parts are most susceptible to wear and tear enables you to prioritize repairs, ensuring your equipment continues to operate at its best.

Commonly Worn Out Elements

Certain components experience frequent stress during use, making them more prone to damage. By identifying these areas early, you can avoid larger issues down the line. Commonly affected parts often include moving elements, connectors, and areas exposed to friction or heat.

How to Spot Faulty Components

Spotting faulty parts before they cause complete failure can save time and reduce repair costs. Pay attention to signs like unusual noises, diminished performance, or visible wear. A thorough inspection allows you to pinpoint these issues before they escalate.

How to Use the Assembly Guide Effectively

Utilizing a visual reference is essential for simplifying the maintenance process. An organized illustration of your tool’s inner workings allows for quick identification of the components, making it easier to perform repairs or replacements accurately.

To use the guide efficiently, focus on the specific area you need to address. This will help you navigate through the illustration and locate the exact component. By following the sequence outlined in the reference, you can ensure that each part is reassembled correctly after servicing.

Additionally, refer to the guide regularly during disassembly or reassembly to avoid any confusion. Understanding the connection between parts and their positions will prevent mistakes and make the process smoother and more efficient.