When working with complex machinery, having a clear understanding of its internal structure is essential. Identifying the various elements that contribute to the overall functionality helps ensure smoother operation and maintenance. A comprehensive overview of the system’s components allows operators to recognize how each part interacts and performs its specific role.

Accurate identification of these components is vital for troubleshooting and repairs. Knowing where each element is located and how it fits into the overall design facilitates quicker fixes and reduces downtime. Whether you’re a technician or a machine operator, understanding these parts can significantly improve efficiency and safety in the workplace.

By familiarizing yourself with this breakdown, you can easily pinpoint potential issues and maintain peak performance. A structured view of the system’s composition gives you the tools to ensure everything runs as expected, extending the longevity of the equipment and optimizing its capabilities.

Understanding the Machine Layout

Familiarity with the internal arrangement of any piece of heavy equipment is crucial for both operation and maintenance. By recognizing the configuration of key components, you can better comprehend how each part supports the overall functionality of the system. A well-organized structure enables smoother interactions between different units, ensuring that the machine works efficiently and effectively.

Each section of the machine has a specific purpose, and understanding how these areas are laid out can help with troubleshooting and repairs. The components are strategically positioned to maximize accessibility while maintaining a compact design. Recognizing the layout helps in identifying possible weak points or areas that may require attention.

Having a clear understanding of the overall layout also allows for faster identification of necessary maintenance tasks, as you can pinpoint problem areas with ease. This knowledge can also assist in regular upkeep, making sure that all parts are functioning as intended. A solid grasp of the machine’s structure is key to ensuring optimal performance and preventing unnecessary delays in the field.

Key Components of Machine

Understanding the essential elements of any machinery is vital for efficient operation. Each component serves a specific role in ensuring the machine runs smoothly. These fundamental parts work together to create a cohesive system, where each unit’s function complements the others for optimal performance.

The main components of the system are designed to handle various tasks, from power transmission to stability control. Below are some of the critical elements found in the structure:

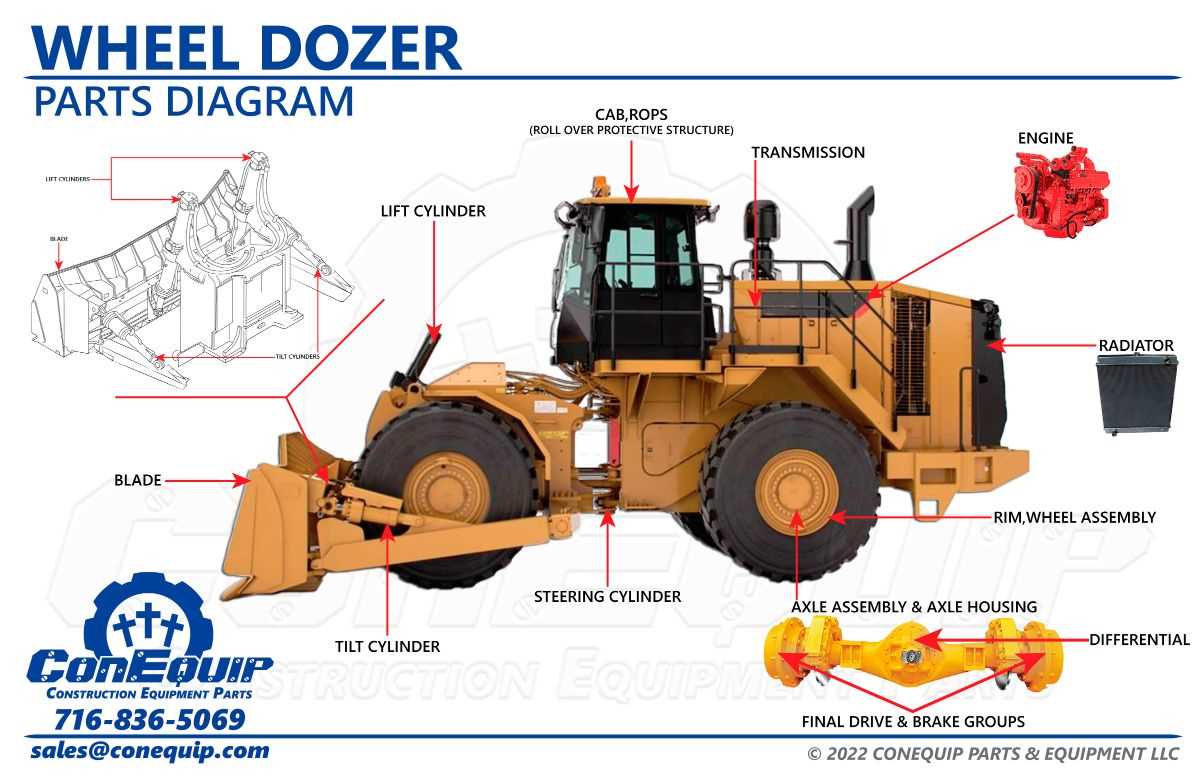

- Engine: Provides the necessary power to drive all mechanical functions, ensuring the machine operates effectively.

- Hydraulic System: Responsible for powering essential functions such as lifting and tilting, offering the versatility required for various tasks.

- Transmission: Transfers the power generated by the engine to the wheels or tracks, enabling movement and speed control.

- Undercarriage: Provides stability and support to the entire machine, ensuring balance on uneven surfaces.

- Cooling System: Maintains optimal operating temperatures to prevent overheating, keeping the engine and other critical systems functioning properly.

Each of these components plays a vital role in the machine’s overall performance, and understanding their specific functions is essential for both maintenance and troubleshooting. By knowing how these elements interact, operators can ensure that the equipment is always in good working condition.

How to Use the Components Layout

Understanding how to navigate the layout of machine elements can significantly enhance the efficiency of maintenance and repairs. A detailed visual representation of the internal structure serves as a guide to identifying each unit and understanding its relationship with other components. By using this layout effectively, operators and technicians can quickly pinpoint areas that may need attention.

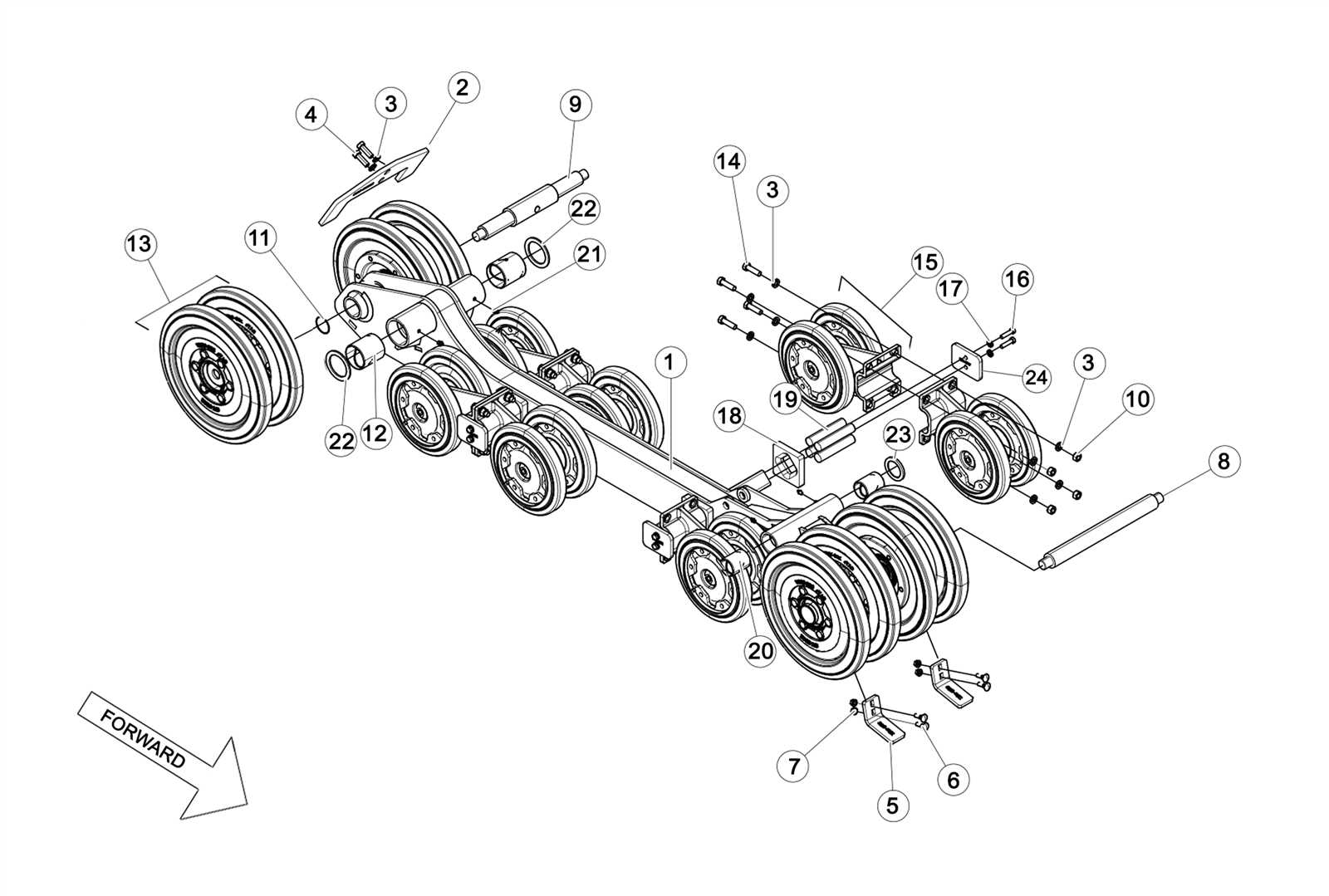

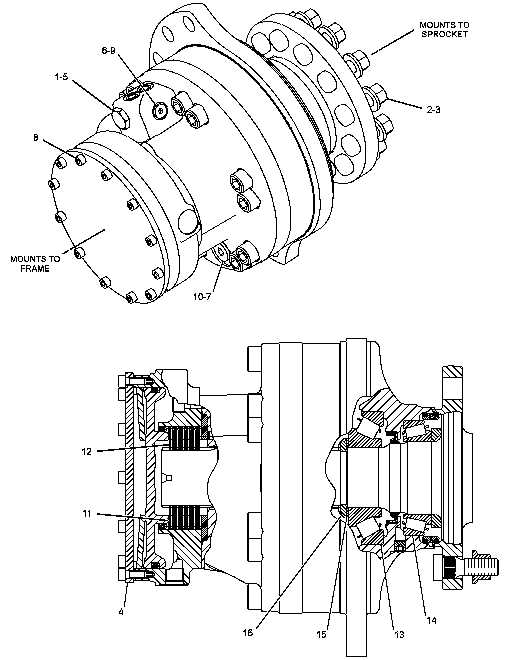

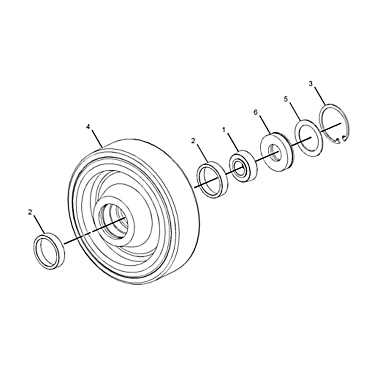

Identify Key Sections

The first step in using the visual layout is identifying the major sections of the machine. Each group of components typically serves a specific function, such as power distribution or mechanical support. By locating these areas on the diagram, you can focus on the relevant units when performing inspections or repairs.

Locate and Reference Specific Components

Once the major sections are identified, you can use the diagram to find individual components. These visual aids often include labels or numbers that correspond to specific parts, allowing for easy reference. When troubleshooting an issue or performing routine maintenance, this step helps to quickly locate the part in question and understand its function within the overall system.