Understanding the inner workings of an engine is essential for effective upkeep and repair. Knowing where each individual element fits and how they contribute to the overall performance ensures that you can handle any challenges that arise.

The detailed layout of engine components provides a clear overview of the system. This map allows anyone working with the machine to identify specific pieces quickly, enabling faster fixes and minimizing downtime.

Familiarity with the various sections of the assembly is crucial for both routine maintenance and addressing any malfunctions. By understanding how the parts are arranged and connected, you’ll be able to make informed decisions during repairs and upgrades.

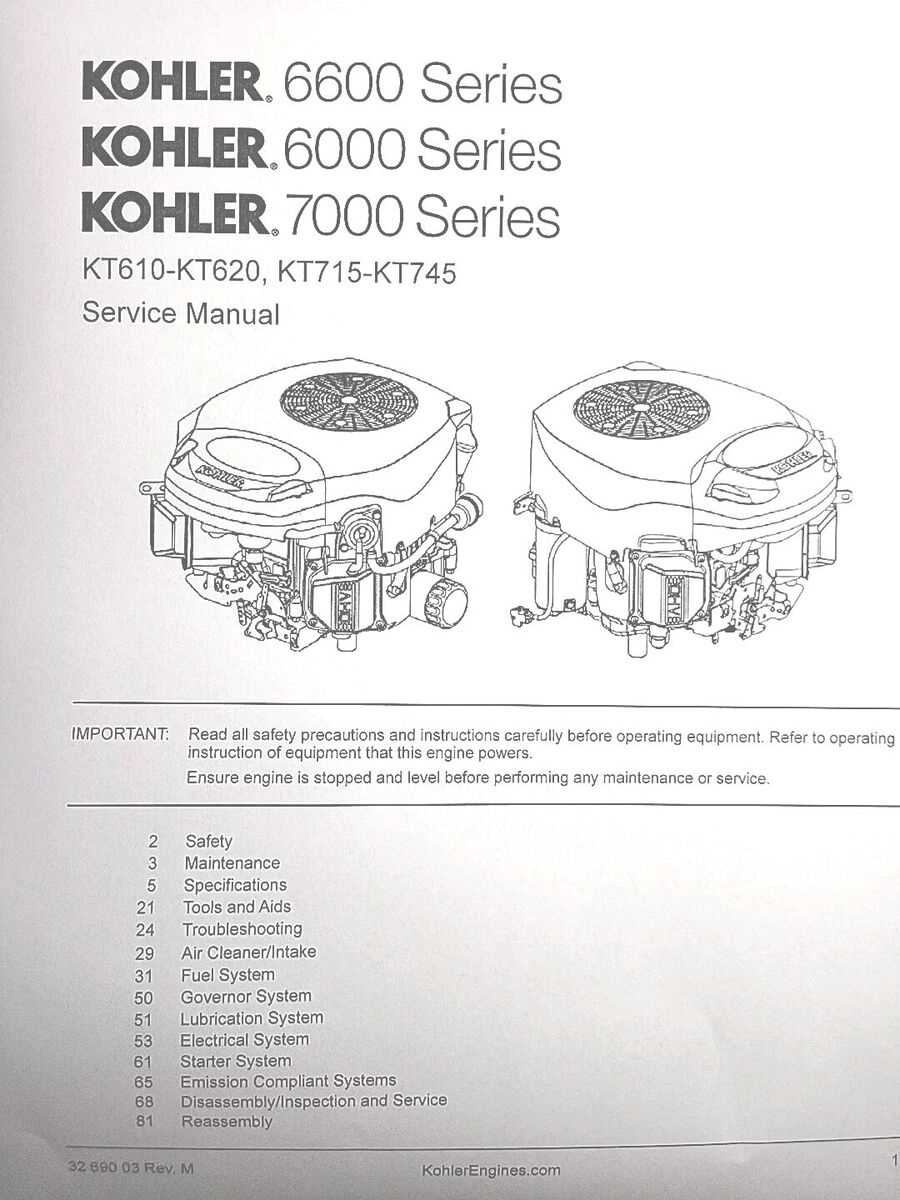

Kohler KT745 Engine Breakdown

Understanding the structure of a small engine is essential for anyone involved in its maintenance or repair. Each component serves a specific role in ensuring the overall system functions smoothly. By familiarizing yourself with the layout, you can tackle both routine servicing and unexpected issues with confidence.

The engine consists of several key sections, including the fuel system, ignition, and mechanical parts, all working together to produce power. By analyzing the breakdown of these sections, you can pinpoint potential areas that may need attention or replacement over time.

With a clear understanding of how each section is connected and how the parts interact, the process of troubleshooting becomes more straightforward. This approach allows for efficient repairs and optimal performance, reducing the risk of unnecessary downtime.

Understanding Key Components of KT745

In order to effectively maintain or repair a machine, it’s crucial to understand its key elements and how they function together. Each part plays a vital role in keeping the system running efficiently, and a thorough understanding of these components ensures that any issues can be addressed with ease.

Mechanical System Overview

The mechanical system is the backbone of the engine, responsible for converting energy into motion. Key elements in this section include the crankshaft, pistons, and connecting rods. These components work in unison to produce the necessary force for operation, making their condition critical for the machine’s performance.

Fuel and Ignition Systems

Equally important are the fuel and ignition systems, which control the combustion process. The fuel system regulates the flow of fuel, while the ignition system ensures the spark needed for ignition is delivered at the right moment. Proper maintenance of these systems is essential for smooth and efficient engine operation.

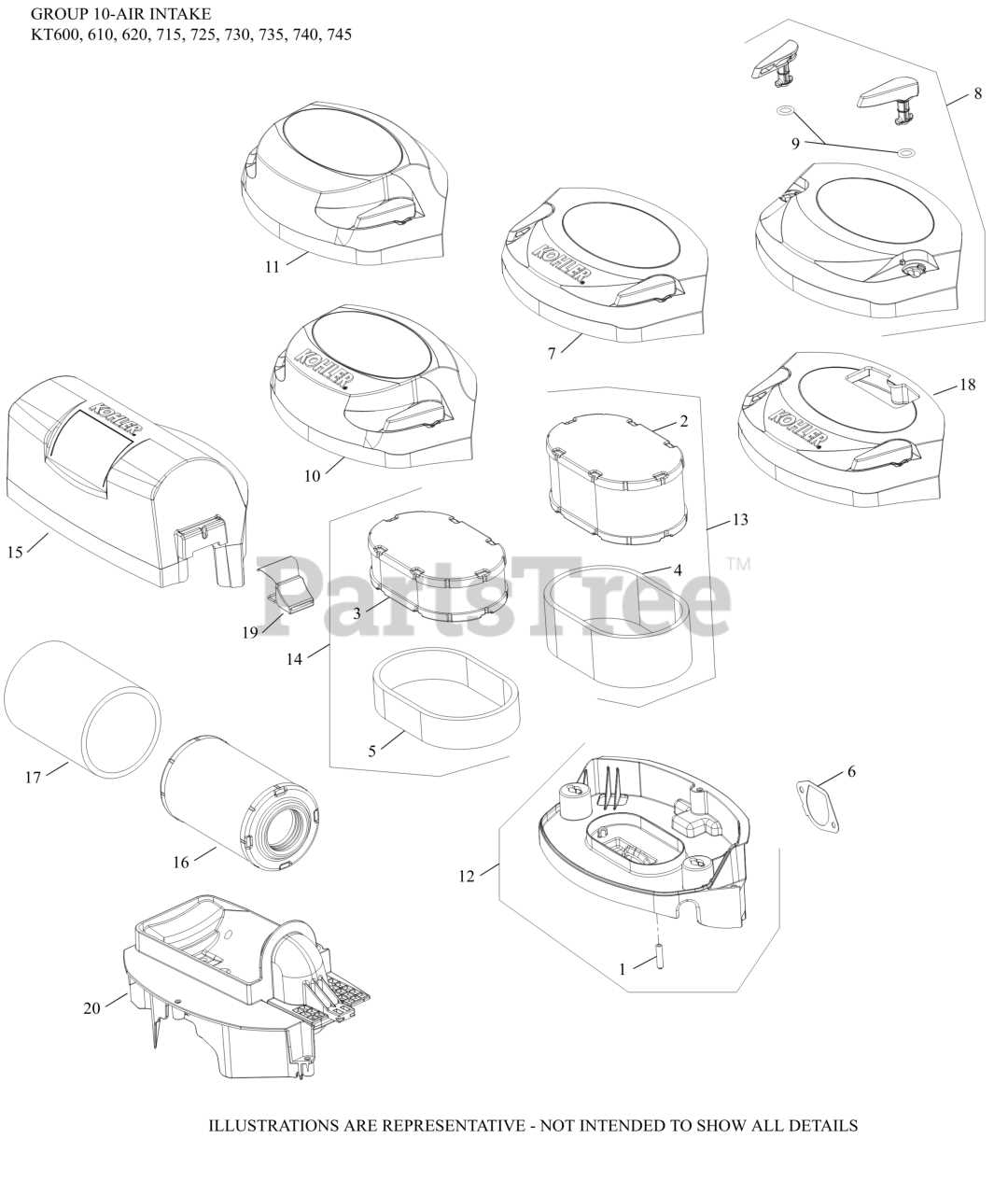

How to Use the Parts Diagram

To effectively navigate through a breakdown of components, it’s essential to understand how to interpret the visual guide that illustrates the assembly. This tool provides a clear representation of how different elements are arranged, allowing for easy identification of each part and its role within the system.

By referencing the guide, you can quickly pinpoint the specific part you need to address or replace. The diagram will often include numbers or labels, which help you correlate the part with its description or specifications in the manual. This makes troubleshooting and repair more efficient, reducing the time spent searching for a particular component.

For optimal use, always ensure you’re working with the correct version of the guide that corresponds to the exact model of the machine. This ensures accuracy and helps avoid confusion when comparing parts and their configurations.