When working with small engines, understanding the layout and structure of their components is crucial for proper maintenance and repair. Every engine is made up of various parts that interact to ensure smooth operation. Familiarity with these components allows for quicker troubleshooting and efficient replacements when necessary.

Effective maintenance hinges on knowing where each component is located and how it functions. Whether you are replacing worn-out pieces or conducting routine checks, being able to identify each part easily can save time and effort.

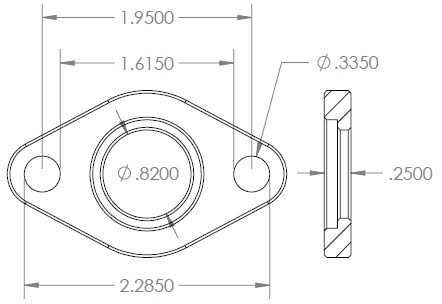

Detailed illustrations of engine parts provide clarity and act as a helpful guide during repairs. They not only show how components fit together but also highlight potential issues to look for when performing maintenance tasks. Understanding these visuals is essential for anyone looking to improve their skills in engine upkeep.

Understanding Engine Components

To maintain and repair any small engine, it’s essential to have a clear understanding of its individual components. Each element plays a specific role in the overall functioning of the engine, and knowing how they interact is key to ensuring proper performance. Without this knowledge, diagnosing issues or performing repairs can become a challenging task.

Engine assembly consists of various interconnected systems that work together to generate power. From the fuel system to the ignition and cooling mechanisms, every piece is critical. Identifying and locating each part is the first step in performing an efficient repair or upgrade.

Detailed views of engine assemblies are particularly useful when it comes to recognizing the function and positioning of each component. With these visual aids, even complex systems can be easily understood, ensuring a more straightforward approach to troubleshooting and maintenance. Knowing what to look for and where it is situated can significantly reduce time spent on repairs.

How to Read the Engine Assembly Illustration

Understanding how to interpret engine assembly illustrations is a crucial skill for anyone involved in engine maintenance. These visual guides provide a detailed view of how components fit together and interact with one another. By studying them carefully, you can identify the exact location of each part and understand its function within the overall system.

To read these illustrations effectively, focus on the labels and numbering systems. Each component will usually be identified with a specific number or code, which corresponds to a detailed list or legend. This system makes it easy to locate the part you need to examine or replace.

Additionally, pay attention to the orientation and connections between parts. The layout typically shows how different components are aligned and connected, which is especially useful for understanding the engine’s assembly and disassembly process. With practice, interpreting these visuals will become more intuitive, making repairs and maintenance more efficient.

Common Issues and Part Replacements

Engines, like all mechanical systems, are prone to wear and tear over time. Identifying common issues early can help prevent more serious damage and ensure that the engine continues to operate efficiently. Regular inspection and timely part replacement are essential for maintaining optimal performance.

Worn-Out Components

One of the most frequent issues is the wear of essential components, such as seals, gaskets, and bearings. These parts are subjected to constant stress and friction, which can lead to deterioration. Replacing these parts promptly can prevent leaks, overheating, and reduced engine efficiency.

Fuel and Air System Failures

The fuel and air delivery systems are vital for engine operation. Clogged fuel lines, air filters, or damaged carburetors can cause the engine to run poorly or fail to start altogether. Regular cleaning and replacing these components as needed will help maintain smooth operation and extend the engine’s lifespan.