Maintaining and repairing your sprayer requires a clear understanding of its individual components and how they work together. Knowing the function of each part can significantly improve the efficiency and longevity of the device. Proper knowledge of assembly and disassembly is key to ensuring smooth operation and preventing future issues.

Having access to a detailed illustration or guide can greatly aid in the process. With a clear visual representation, you can quickly identify parts that need attention or replacement. This also simplifies the troubleshooting process, allowing you to focus on specific areas that may be causing problems.

Whether you are performing regular maintenance or tackling a more complex repair, having a thorough understanding of your sprayer’s internal structure is essential. With the right knowledge, you can keep your equipment in top condition and avoid unnecessary downtime.

Understanding Paint Sprayer Components

When working with a high-performance sprayer, it’s crucial to understand the individual components that ensure its optimal operation. Each element, from the motor to the fluid delivery system, plays a significant role in achieving precise and efficient results. Familiarizing yourself with the internal structure helps with proper maintenance, troubleshooting, and repairs.

Key Components to Focus On

The motor, pump, and fluid intake systems are the heart of the sprayer. Understanding their functions can assist in diagnosing issues and replacing worn-out elements. Additionally, the nozzle and spray tip control the application of the paint, affecting the overall finish quality. Regular inspection of these components ensures the device operates smoothly, reducing the likelihood of downtime during use.

Maintaining Sprayer Efficiency

Proper maintenance involves checking for blockages, cleaning filters, and ensuring all seals and gaskets are in good condition. Replacing worn or damaged components as needed will prevent further damage and maintain the sprayer’s performance. With a well-maintained system, users can expect consistent results and longer lifespan for their equipment.

How to Read the Paint Sprayer Blueprint

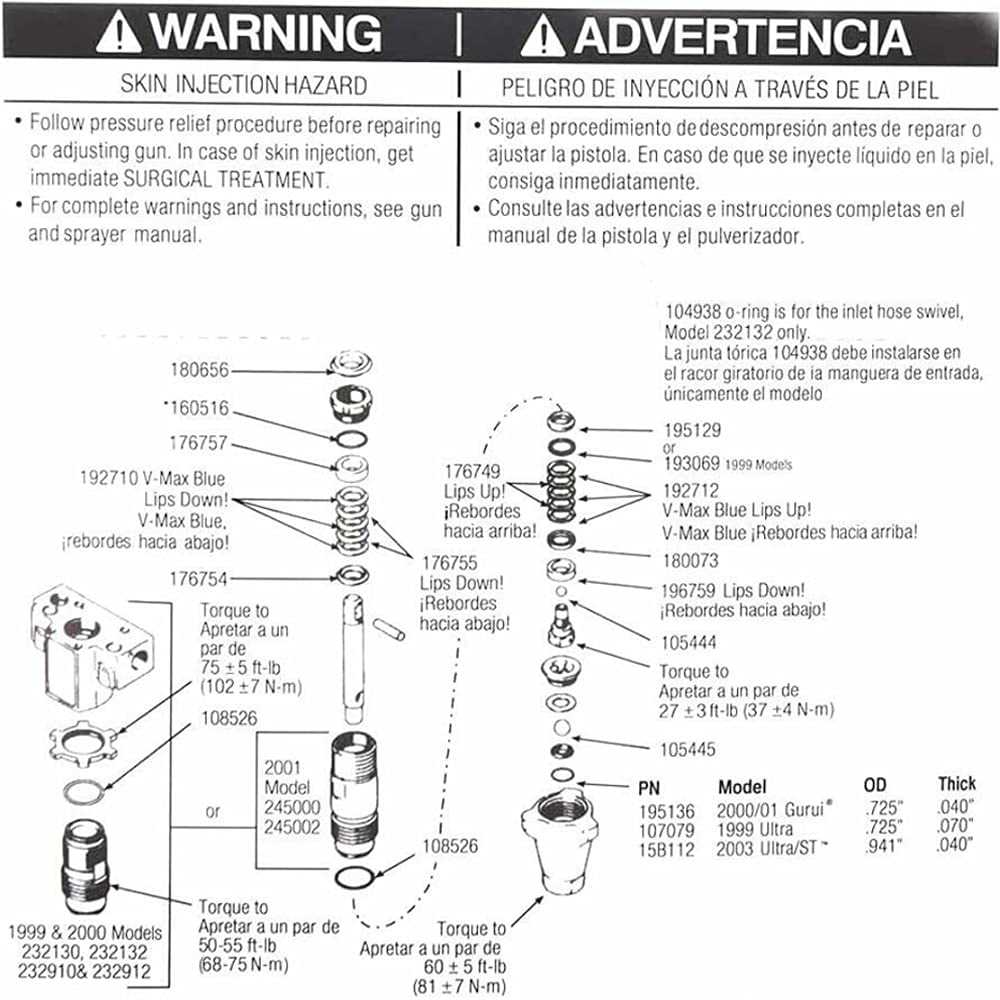

Understanding a sprayer’s schematic is essential for proper maintenance and repair. A well-designed blueprint provides a clear visual representation of the device’s internal structure, showing the positioning of each component. Learning how to interpret this information ensures efficient assembly, repair, and troubleshooting.

When looking at the schematic, pay attention to the different symbols and labels used to represent each element. These diagrams typically include lines connecting components, indicating their relationships and how they interact within the system. Each part is often numbered or labeled, helping you quickly locate it within the assembly or pinpoint specific areas for inspection.

Understanding the flow of fluid and air through the system is another key aspect of reading the blueprint. This can guide you in identifying potential issues, such as clogs or misalignments, that may be affecting the sprayer’s performance. A thorough understanding of these diagrams helps avoid common mistakes and ensures the sprayer functions as intended.

Essential Maintenance Tips for Paint Sprayer

To ensure long-lasting performance and reliable results, it’s crucial to follow a regular maintenance routine for your sprayer. Proper care not only extends the lifespan of the equipment but also prevents common issues such as clogging or inefficient spraying. A few simple steps can make a significant difference in the efficiency of the system.

Regular Cleaning and Inspection

Routine cleaning is one of the most important aspects of maintenance. After each use, make sure to clean the nozzle, pump, and fluid delivery system thoroughly. This prevents paint build-up, which can lead to blockages and reduced spray quality. Regularly inspecting seals, gaskets, and hoses also helps identify any wear or damage early, reducing the risk of more serious issues.

Lubrication and Part Replacement

Lubricating moving parts, such as the pump and motor, is essential to keep everything running smoothly. Over time, some components may wear out or degrade, especially rubber seals and gaskets. Replacing these parts promptly ensures your equipment continues to function at its best and prevents leaks or malfunctions.