Every mechanical tool consists of a variety of essential components that work in harmony to deliver optimal performance. Recognizing and understanding these individual pieces is crucial for both repair and maintenance. Knowing the layout and functionality of each part helps ensure that the device continues to operate effectively over time.

Proper maintenance begins with a clear understanding of how each element fits together and contributes to the overall functionality. Whether you’re troubleshooting an issue or performing routine servicing, having access to a detailed breakdown can make a significant difference in achieving a successful outcome.

Efficiency and longevity depend on recognizing the role of each part and following the right steps for care. With a comprehensive guide, you can avoid common mistakes and improve the tool’s overall lifespan, ensuring it stays in top working condition for years to come.

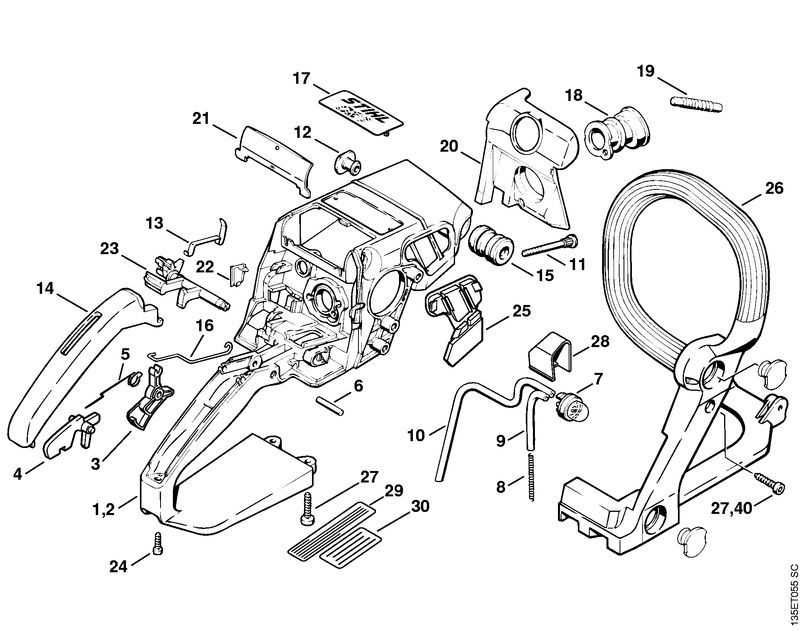

Understanding the Components of STIHL 025

Every tool designed for heavy-duty tasks relies on a combination of specialized elements that ensure smooth operation. Each component has its unique role, and when they work together, they contribute to the overall efficiency and reliability of the machine. Knowing how each piece functions allows users to troubleshoot problems effectively and perform maintenance tasks with precision.

Key Functional Elements

One of the most critical aspects of tool maintenance is understanding the purpose of each individual part. The core components are designed to handle specific functions such as power transmission, safety, and operational controls. Identifying and inspecting these pieces can help identify potential issues that may affect the performance of the entire unit.

Common Wear and Tear

Like any mechanical device, certain parts are more prone to wear over time. Moving elements and those exposed to high stress or heat tend to degrade faster. Regular checks and replacements of these components are essential for preventing malfunctions and extending the tool’s life. Familiarity with these common points of failure ensures users can act promptly when necessary.

Step-by-Step Guide to STIHL 025 Assembly

Assembling a complex tool requires careful attention to detail and a structured approach to ensure all components are correctly aligned and secured. By following a methodical process, you can ensure that each part is properly placed, contributing to the overall functionality and safety of the device. This guide will walk you through the necessary steps to put everything together efficiently and correctly.

Start by organizing all the components and making sure you have all the necessary tools at hand. Carefully examine each part to ensure there are no defects or damage before assembly begins. Begin with the larger structural components and work your way to the smaller, more intricate pieces. This approach minimizes errors and makes the entire process more manageable.

After assembling the main body, move on to attaching the operational elements. Pay close attention to the alignment and fitting of the parts to avoid unnecessary strain or malfunction. Tighten all screws and bolts securely, but avoid over-tightening, which could lead to part damage.

Finally, once the assembly is complete, conduct a thorough inspection to ensure everything is in place and functioning as expected. A quick test of the tool can help identify any issues early, allowing you to address them before the first use.

How to Maintain Your STIHL 025 Efficiently

Proper maintenance is essential to keeping your tool running smoothly and extending its lifespan. Regular care prevents minor issues from turning into major problems, ensuring that it performs at its best over time. Following a consistent maintenance routine can help you avoid costly repairs and improve the overall efficiency of the device.

Start by cleaning the tool after every use. Dust, debris, and moisture can cause wear and reduce performance, so it’s important to wipe down surfaces and remove any buildup. Regularly check the moving components, such as gears and levers, to ensure they are free of obstructions and properly lubricated.

Another crucial maintenance step is inspecting the operational elements for signs of wear. Parts that undergo heavy use, like those involved in power transmission, may need replacement over time. Keeping track of the condition of these pieces and replacing them when necessary will keep the tool in optimal working condition.

Lastly, always store the equipment in a dry, cool place to prevent corrosion and damage from environmental factors. By following these simple yet effective steps, you can ensure that your tool remains reliable and performs at its peak for years to come.