Proper maintenance of outdoor power equipment requires a clear understanding of its individual components. Identifying and replacing parts effectively ensures the smooth operation of your device, allowing it to perform at its best for years to come. Knowing how each piece fits into the overall system can save time and reduce the risk of damage during repairs.

Accurate knowledge of the structure of your machine is essential for quick troubleshooting. When issues arise, being able to locate and identify the faulty part can significantly reduce downtime. This guide provides essential insights into identifying various elements and understanding their functions.

Maintaining outdoor machinery requires more than just simple cleaning and refueling; understanding the specific role of each piece allows for precise adjustments and replacements. By following a clear guide, you can make informed decisions, whether it’s a minor tweak or a full replacement of worn-out components.

Understanding the Echo PB-2520 Parts Diagram

Grasping the structure of your outdoor equipment is crucial for effective maintenance and repair. Every machine consists of a network of interconnected components, each playing a specific role in its operation. Having a clear understanding of how these parts interact can lead to smoother repairs and better overall performance.

Key Components and Their Functions

The first step in understanding the structure of your device is to familiarize yourself with its essential components. Each part serves a unique function that contributes to the machine’s overall efficiency. Here are some common parts you should be aware of:

- Power Unit: Responsible for generating the necessary energy to operate the device.

- Handle and Trigger Mechanism: Allows the user to control the equipment’s power and functionality.

- Fuel System: Stores and delivers fuel to the engine for smooth operation.

- Cutting Mechanism: The part that directly interacts with the material, performing the cutting or trimming task.

How to Identify and Replace Faulty Components

When a problem arises, understanding the function of each part helps you identify the source of the issue quickly. Common problems may include engine failure, malfunctioning controls, or inefficient cutting. Here’s how to approach the replacement process:

- Inspect the component thoroughly to determine if it’s worn out or damaged.

- Consult the manual for the correct part numbers and installation steps.

- Carefully remove the faulty part and replace it with a compatible component.

- Test the equipment to ensure proper functionality after replacement.

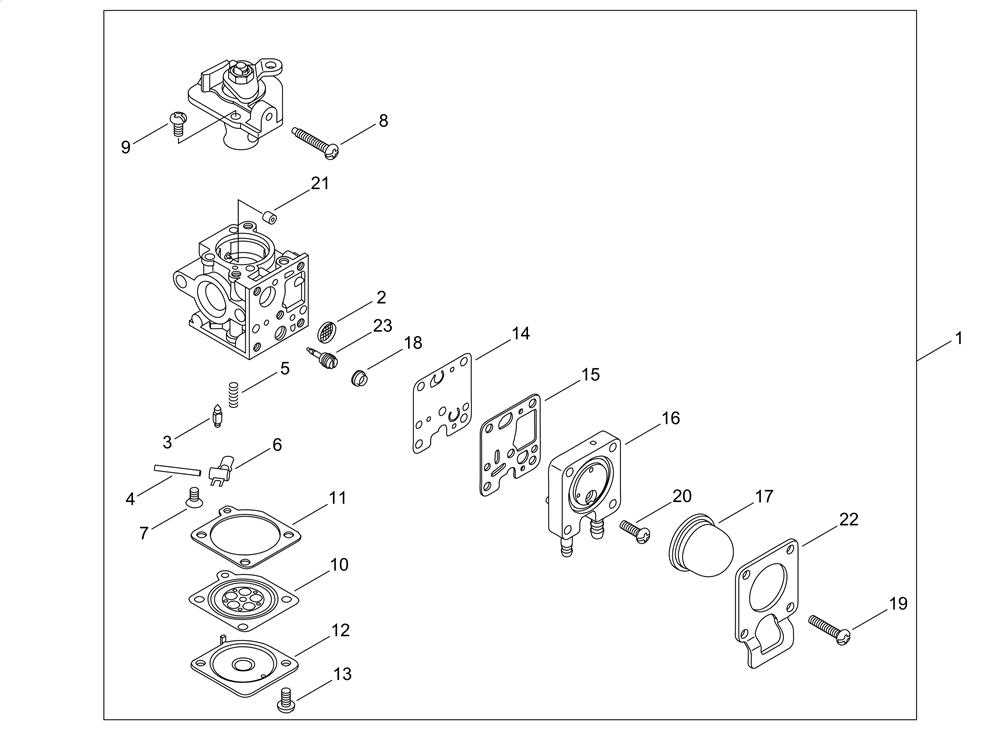

How to Identify Key Components in the Diagram

Knowing how to recognize and locate each essential element in your equipment’s schematic is vital for performing accurate repairs and maintenance. A detailed visual representation of the system can help pinpoint where each part fits and how it contributes to the machine’s overall performance. This section will guide you through the process of identifying the most crucial elements in the layout.

Understanding the Structure of the Layout

The first step in navigating the visual layout is understanding its general structure. Most schematics are organized with clear labels and sectioned-off areas. These sections often represent different parts of the machine, such as the power system, the control unit, and the cutting mechanism. Pay attention to these categories to better follow the flow of energy and movement within the device.

Common Components to Identify

Focus on the most critical parts when reviewing the layout. The following are some of the primary elements that you should be able to identify easily:

- Power Source: This part is responsible for providing energy to the machine and is usually placed prominently in the schematic.

- Control Mechanism: Often represented by buttons or levers, this component allows the user to operate the equipment.

- Movement Parts: These include any elements responsible for mechanical movement, such as gears, belts, or pulleys.

- Safety Features: Components that ensure the machine operates safely, including any safety locks or emergency stops.

Common Repairs and Replacements for Echo PB-2520

Over time, outdoor equipment may require specific repairs or part replacements due to wear and tear. Regular maintenance ensures that the machine operates smoothly and effectively. Recognizing common issues and knowing how to address them promptly can extend the lifespan of your equipment and prevent further damage.

Frequent Repairs

Some components tend to experience more stress during use, leading to frequent malfunctions. These are often the parts that need repair or replacement:

- Engine Problems: The engine may experience issues such as stalling or difficulty starting, often caused by fuel system blockages or spark plug problems.

- Fuel System Issues: If the engine is not running smoothly, it may be a sign of fuel delivery problems, such as clogged fuel filters or damaged fuel lines.

- Air Filter Maintenance: A clogged or dirty air filter can reduce engine efficiency and needs regular cleaning or replacement.

Component Replacements

When repairs are no longer sufficient, certain parts may need replacing. These are some of the most commonly replaced items:

- Cutting Mechanism: Blades or cutting lines may become dull or damaged, requiring replacement to maintain cutting performance.

- Control Mechanism: The throttle, switch, or trigger may wear out with heavy use and need to be replaced to restore proper operation.

- Handles and Grips: Over time, handles may crack or lose their grip, making them uncomfortable or unsafe to use. Replacing them can improve comfort and control.