When it comes to maintaining and repairing lawn care equipment, having a clear understanding of its internal elements is essential. Knowing the specific components and their functions helps ensure that your tools operate efficiently and last longer. Proper identification of each part is key to addressing any issues that may arise during use.

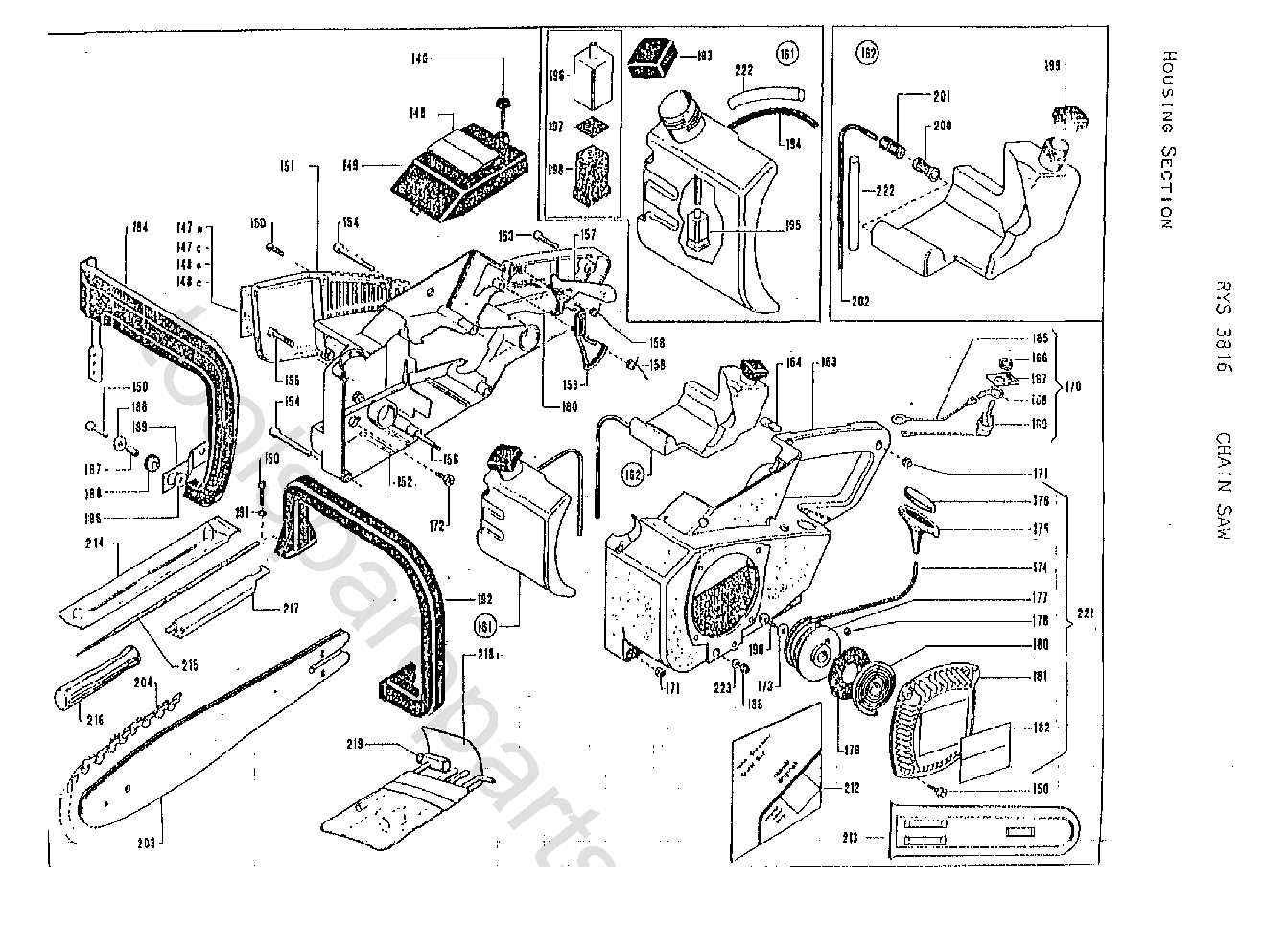

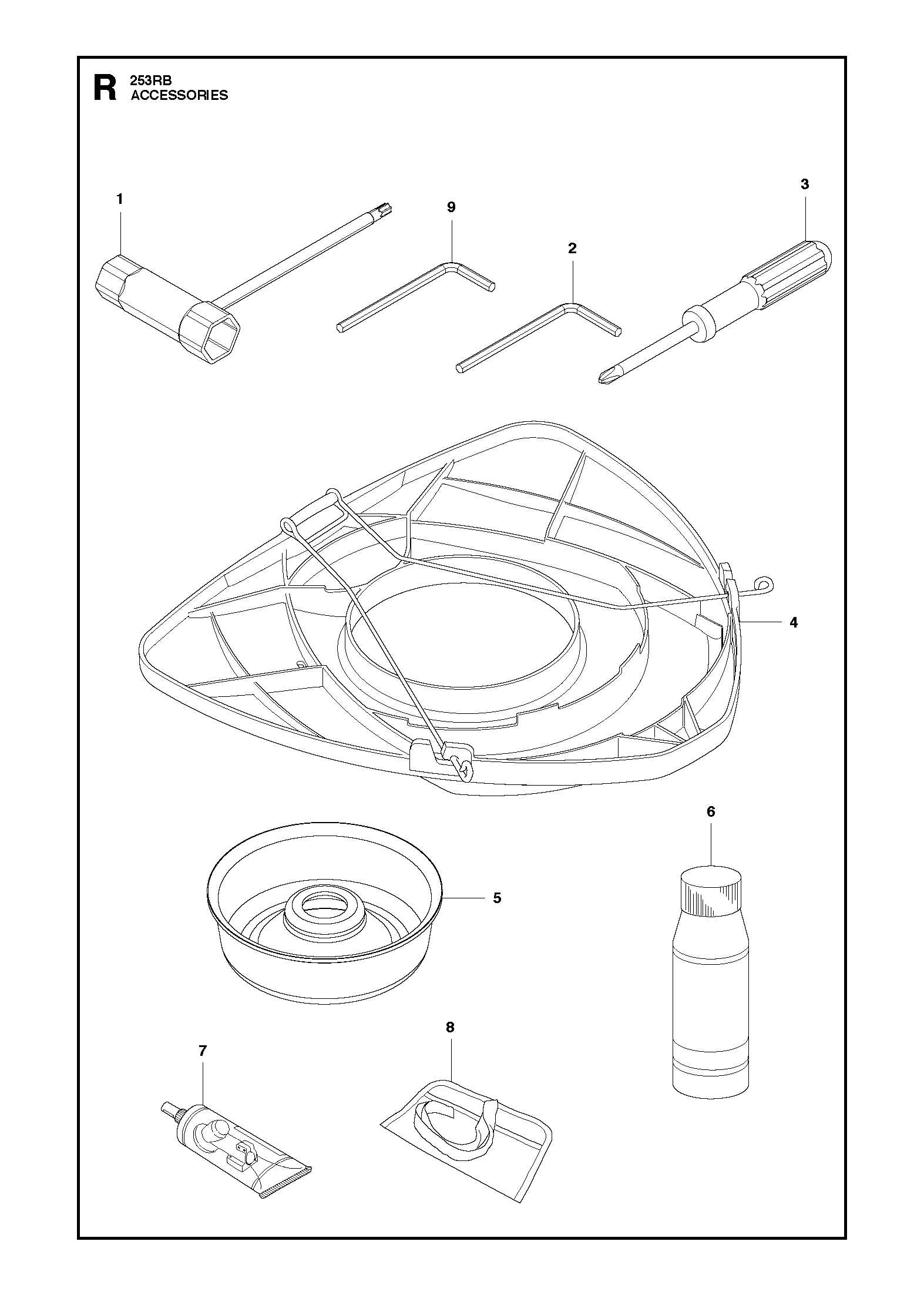

Visual guides play a critical role in simplifying the identification process. They provide a detailed view of the various components, helping users distinguish between similar parts. Whether you’re troubleshooting a problem or performing routine maintenance, understanding where each piece fits in the overall structure is crucial for effective repairs.

In this guide, we will explore the various essential components of your equipment. We will look at how to spot common issues and how to address them by recognizing individual parts and their interactions. This knowledge empowers users to make informed decisions, saving both time and money during repairs.

Understanding Stihl RB 200 Components

Effective operation of any piece of equipment relies heavily on the proper functioning of its individual components. Every tool consists of various elements that work together to perform its intended tasks. Identifying and understanding these components is essential for proper care, maintenance, and troubleshooting.

The engine, motor, and mechanical features all play specific roles in the overall performance. Each part is designed to interact seamlessly with others, ensuring the smooth functioning of the entire machine. Knowing how these components fit into the larger assembly helps in diagnosing potential issues and preventing unnecessary wear.

In this section, we will delve into the core elements that make up the system. By breaking down each piece and its function, we aim to offer clarity on how to properly maintain your equipment. Understanding these components will not only simplify the repair process but also contribute to better overall performance and longevity of the machine.

How to Identify Stihl RB 200 Parts

Identifying individual components in any machinery is a crucial step when it comes to repairs or replacements. Each part has its unique role and contributes to the overall function of the equipment. Recognizing the correct piece and understanding its placement can save time and ensure proper maintenance.

Visual aids such as clear illustrations or images can help in this process. They allow users to match the component with its specific location in the machinery. By referring to these resources, one can easily distinguish between parts that may appear similar in design but differ in function or connection.

It is also important to understand the interaction between components. Knowing how one part affects another will not only help in identifying it but also in troubleshooting any potential issues. Once you can recognize each individual part and its purpose, you will be better equipped to perform maintenance or repairs on your equipment efficiently.

Common Stihl RB 200 Repair Issues

Even the most durable equipment can experience issues over time, and knowing what to look for is essential for effective repairs. Identifying common problems early can prevent more serious damage and help maintain optimal performance. Understanding typical issues will also make the repair process smoother and more manageable.

Here are some of the most frequent problems that users may encounter:

- Fuel Supply Problems: Difficulty in starting or inconsistent operation can be caused by issues with the fuel system, such as clogged filters or lines.

- Air Filter Blockages: A dirty or clogged air filter can lead to poor engine performance, requiring cleaning or replacement to restore proper airflow.

- Motor Overheating: Excessive heat buildup may occur due to insufficient lubrication or cooling, leading to potential engine damage if not addressed.

- Wear and Tear on Belts: The belts can deteriorate over time, causing slipping or failure, which impacts the efficiency of the equipment.

- Faulty Electrical Connections: Loose or damaged wiring can result in intermittent operation or failure to start.

By staying vigilant and addressing these issues promptly, you can ensure that your equipment remains in good working condition for an extended period. Regular maintenance and quick fixes will help avoid major repairs and keep the machine running smoothly.