When it comes to keeping your machinery in optimal condition, having a clear understanding of its inner workings is essential. Whether you are troubleshooting or performing routine maintenance, knowing where each component fits and functions makes all the difference in the repair process.

Accessing detailed visuals and schematics for your equipment allows you to identify each individual element, from the smallest screws to the larger assemblies. This knowledge empowers you to address issues more efficiently, reducing downtime and ensuring long-lasting performance.

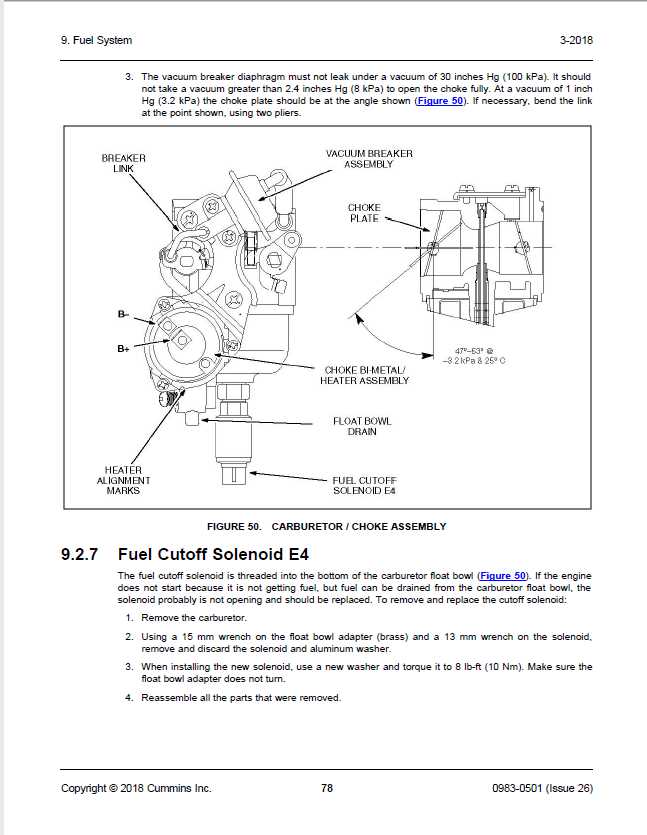

Detailed illustrations serve as a valuable tool for identifying connections, assessing potential damage, and replacing worn-out elements. By familiarizing yourself with the layout of each section, you can save time and avoid unnecessary steps during maintenance tasks.

In this section, you will find practical resources to enhance your understanding of your machine’s structure. From pinpointing problem areas to replacing essential components, these guides will ensure that you can maintain your equipment with confidence.

Understanding Onan 5500 Generator Components

To effectively manage and maintain your equipment, it’s crucial to have a comprehensive understanding of its key elements. Each individual component plays a unique role in the overall operation, and recognizing how they interact helps in diagnosing issues and performing repairs more efficiently.

When working with mechanical devices, it’s important to start with the main assemblies that drive the system’s function. These core components are responsible for power generation, fuel management, and overall system stability. Understanding their roles ensures you can troubleshoot with precision and make informed decisions when performing upkeep or replacements.

Key Functional Elements

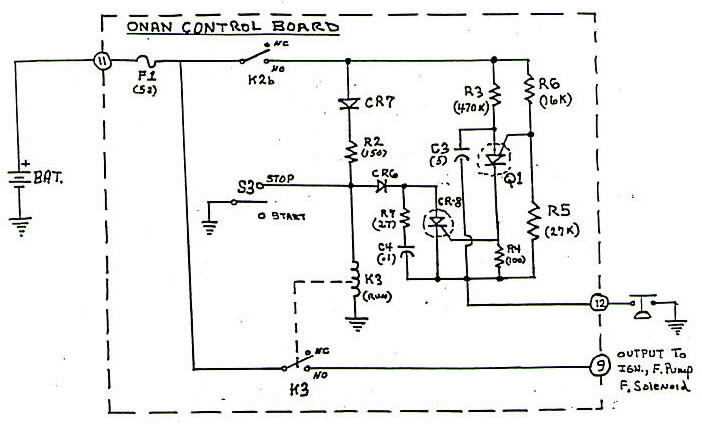

The essential assemblies that make up the entire unit include the power-producing mechanisms, the control systems, and the safety features. The power-generating elements convert energy into usable output, while the control systems regulate the machine’s operations based on feedback from sensors. Safety components are designed to protect both the equipment and the operator from potential damage or hazards during use.

Interconnecting Systems

Various systems work in unison to support efficient functioning. These systems are interconnected through wiring, fuel lines, and sensors that provide data to adjust the unit’s behavior in real time. Understanding how these systems communicate helps identify weak points where failure may occur, allowing for quicker response times during maintenance and preventing future issues.

How to Identify Key Generator Parts

Identifying the critical components of your machine is essential for efficient operation and maintenance. By understanding the layout and functions of each individual element, you can more effectively troubleshoot issues and ensure proper performance. This knowledge is also vital when ordering replacements or upgrading certain sections of the system.

To identify the key elements, start by familiarizing yourself with the main sections of the equipment. These usually include power-producing components, control units, and support mechanisms. Once you recognize the location and purpose of each part, it becomes easier to diagnose problems or locate areas that need attention.

Pay close attention to any labels, color codes, or manufacturer markings that may help in identification. These markings often indicate the type of part, its specifications, and its place within the overall structure. Additionally, referring to the service manual can provide precise details on each component’s function and location.

Common Issues and Repair Solutions

Every piece of machinery faces its fair share of issues over time. Understanding common problems and knowing how to address them ensures that you can restore optimal function quickly. From electrical failures to mechanical breakdowns, identifying and solving issues early can help avoid costly repairs and unnecessary downtime.

One frequent issue is inconsistent power output, which may be caused by fuel system blockages or faulty connections. Ensuring that fuel is flowing properly and that all electrical contacts are secure can often resolve this problem. Regular inspections and cleanings of these systems are key to preventing these interruptions.

Another common issue involves overheating, often due to inadequate ventilation or a malfunctioning cooling system. Checking the airflow and ensuring that the cooling system components, such as fans and heat exchangers, are functioning correctly can significantly improve performance and prevent damage.

Finally, wear and tear on components like belts and seals can lead to mechanical failures. Regularly replacing these parts and ensuring proper alignment can extend the life of the machine and keep it running smoothly for years.