Understanding the intricate system of any machinery is crucial for proper maintenance and troubleshooting. In this guide, we focus on the essential parts of a particular model, offering a clear overview of its structure and key components. With this knowledge, you can ensure longevity and optimal performance of your equipment.

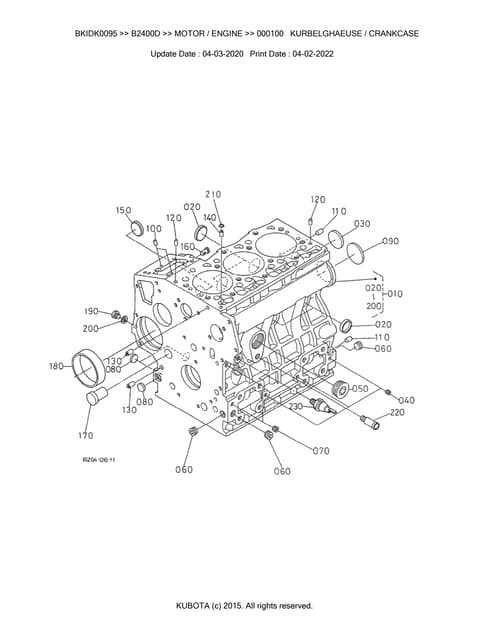

Detailed visual guides provide an easy way to pinpoint specific sections of a machine. By breaking down the main assemblies and sub-components, it becomes simpler to identify worn-out or damaged parts. This is especially valuable when it’s time for repairs or upgrades, as having a comprehensive map of each part’s function helps speed up the process.

Whether you are a professional mechanic or a dedicated hobbyist, understanding the parts of your equipment makes troubleshooting much easier. Knowing where each component is located and how they interconnect empowers you to tackle any issue confidently.

Understanding Tractor Component Layout

Each machine is a complex network of interconnected elements that work together to achieve its purpose. To maintain its performance, it’s essential to understand how these parts are arranged and how they interact. A clear layout of components allows for easier identification of functions and troubleshooting of issues, ensuring smooth operation and longevity.

At the heart of any equipment lies the engine and transmission systems, which are often the most intricate. These are supported by a series of auxiliary systems, including hydraulics, electrical connections, and control mechanisms. Understanding the placement and relationship between these units can help diagnose problems and make repairs more efficient.

When visualizing the layout of a machine, it’s important to consider both the major systems and the smaller components that contribute to overall functionality. Knowing where each part is located and how it fits into the broader framework ensures that maintenance is done accurately and timely, minimizing downtime and reducing repair costs.

How to Navigate the Components Layout Effectively

Mastering the art of interpreting a machine’s visual breakdown is crucial for successful maintenance and repair. A well-structured layout can provide invaluable insight into the relationship between various parts and systems, making it easier to locate specific elements when needed. Navigating through this visual representation can significantly reduce the time spent on troubleshooting and replacements.

Familiarizing Yourself with Major Sections

The first step in understanding a visual layout is recognizing the major sections of the machinery. Typically, these include the engine, transmission, and auxiliary systems such as hydraulics and electrical wiring. By familiarizing yourself with these key areas, you can focus on the specific subsystem relevant to the issue at hand.

Using Labels and References

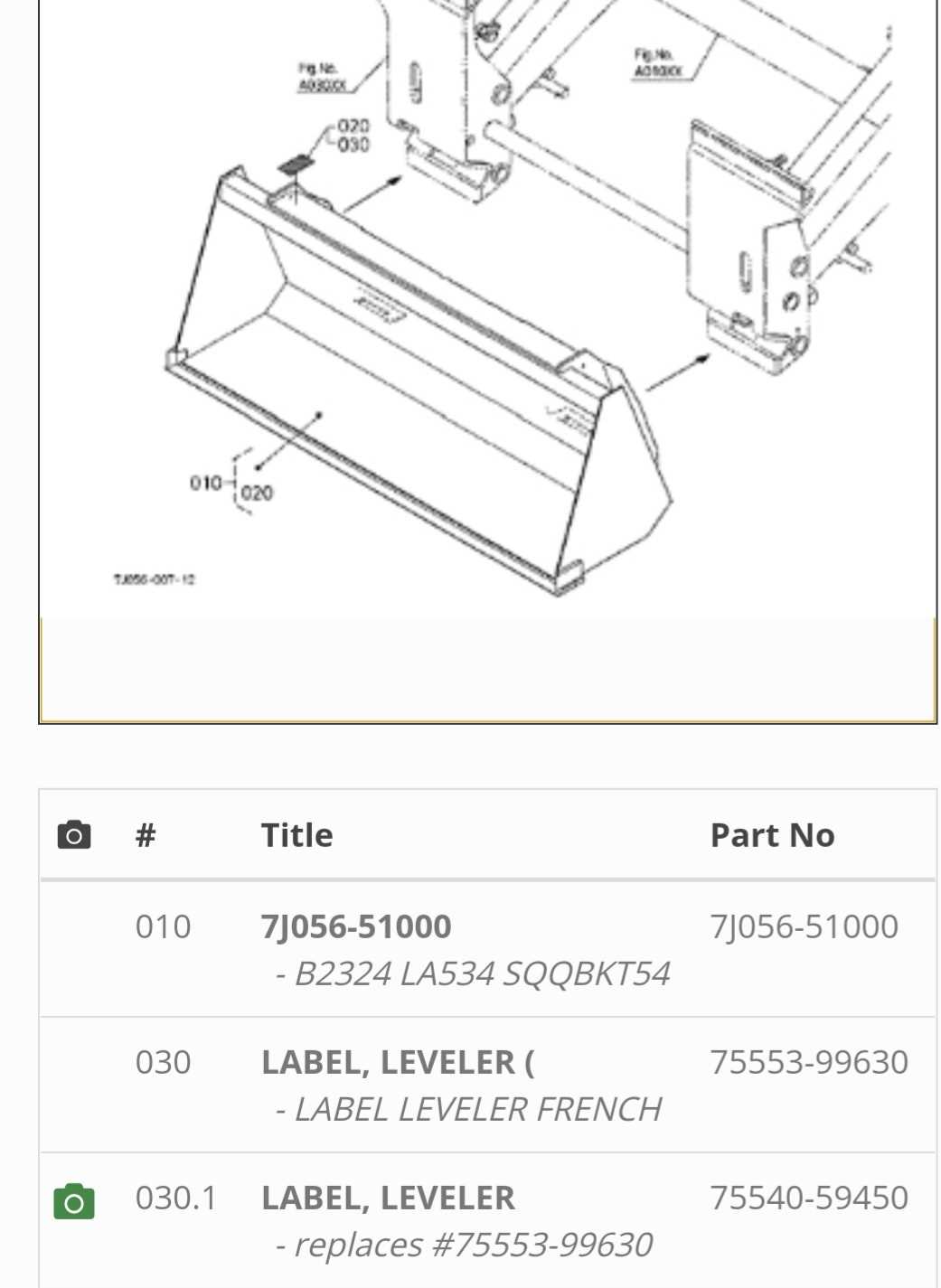

Once you’re familiar with the general layout, the next step is to focus on the labels and references accompanying the visual representation. These often contain essential details like part numbers and specific functions. Paying close attention to these annotations can help you quickly identify the exact component that requires attention or replacement, eliminating the guesswork.

With a clear understanding of how to read and interpret the layout, you can ensure more efficient maintenance and troubleshooting. This knowledge not only saves time but also improves the overall reliability and performance of the equipment.

Common Issues and Parts Identification Tips

When working with machinery, it’s not uncommon to encounter recurring issues that can affect performance. Recognizing these problems early and identifying the faulty components can help resolve them quickly and efficiently. Understanding how to diagnose common failures and pinpoint specific parts can save valuable time and reduce repair costs.

Leaks and Performance Loss are some of the most frequent issues in mechanical equipment. Hydraulic fluid or coolant leaks are often the result of worn-out seals or cracked hoses. Identifying these parts can be made easier by consulting the layout to locate specific components in the fluid delivery system. Inspecting these areas regularly can prevent major damage and ensure smooth operation.

Wear and Tear on Moving Components is another common issue, particularly in systems with high friction, such as belts, bearings, or gears. Over time, these parts can degrade and require replacement. It’s important to regularly check these components for signs of excessive wear, such as unusual noises or reduced functionality. Knowing exactly where to look and which parts to replace ensures that maintenance is done effectively.

By focusing on identifying the key components prone to damage and learning how to spot the signs of wear or malfunction, you can maintain the equipment in optimal working condition and avoid unexpected failures. Regular inspection and timely replacements are crucial for long-term reliability.