Having a clear understanding of a machine’s internal structure is essential for efficient operation and maintenance. A well-organized system of parts allows technicians to easily locate and address any issues that may arise. When tackling repairs or upgrades, knowing how everything fits together simplifies the process and reduces errors.

Visual representations of these systems play a crucial role in enhancing this understanding. They serve as guides, allowing individuals to quickly reference specific areas and parts, ensuring the correct approach to maintenance and troubleshooting. These guides also help in identifying worn or damaged components, making the repair process smoother and more efficient.

With a detailed view of the layout, both professionals and enthusiasts can ensure that every part functions harmoniously. This helps maintain performance and prolong the lifespan of the machinery, ultimately improving its reliability over time.

Understanding Machine Components

Each mechanical system consists of multiple elements working together to ensure smooth operation. Recognizing how these components interact is crucial for identifying issues, performing upgrades, and maintaining optimal functionality. A machine’s efficiency depends on the precise alignment and coordination of all its internal structures.

Key elements within a system can include drive mechanisms, hydraulic systems, and electrical circuits, each playing a vital role. Understanding the function of each individual part helps technicians and users diagnose problems quickly, allowing for targeted solutions rather than broad assumptions. This knowledge contributes to better decision-making when it comes to repairs or replacements.

Comprehending the assembly layout also aids in preventing unnecessary disassembly. By knowing where each component is located and how it connects to others, users can avoid damaging non-relevant parts. This approach streamlines the process, saving time and effort during maintenance tasks.

How to Read the Assembly Layout

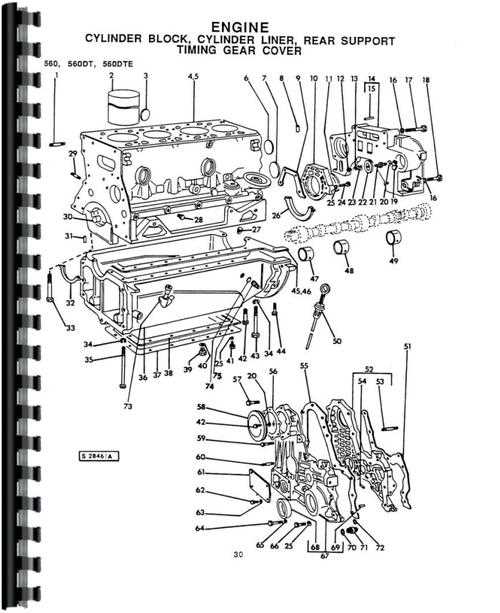

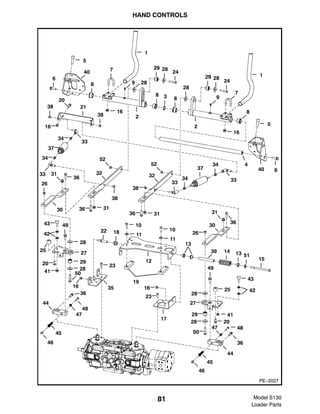

Understanding how to interpret an assembly layout is essential for effective troubleshooting and repair. These visual guides offer a detailed look at the internal components of a machine, helping you to quickly locate specific areas that may need attention. Properly reading these layouts enables users to identify the necessary parts without confusion or unnecessary steps.

Identifying Key Components

Each section of the layout is typically divided into areas that represent different mechanical functions. To begin, look for labels or symbols that correspond to specific parts or groups of components. These markers usually provide valuable information, such as the part number, function, or positioning within the overall system. Familiarizing yourself with these symbols will allow for a faster, more accurate interpretation of the guide.

Understanding Relationships Between Parts

One of the most important aspects of the layout is how components are connected to each other. Pay attention to the lines or arrows that indicate relationships between parts. These connections show how different elements work together to achieve the desired function. By focusing on these relationships, you can better understand how each part contributes to the overall operation of the machine and make more informed decisions during repairs or upgrades.

Common Issues and Solutions

Machines often face recurring problems that can affect performance or cause disruptions in operation. Recognizing these issues early on and understanding how to address them effectively is crucial for maintaining smooth functionality. Knowing the common challenges allows operators and technicians to resolve them quickly, minimizing downtime and preventing larger, more expensive repairs.

One of the most frequent issues in mechanical systems involves the hydraulic system. Low fluid levels, air in the system, or leaks can reduce efficiency and cause uneven operation. Regularly checking fluid levels and inspecting hoses and seals can help prevent these problems. If a fault is detected, replacing seals or purging air from the system will usually resolve the issue.

Another common concern is engine performance. Over time, wear and tear can lead to decreased power or unusual noises. Ensuring the engine is regularly serviced, including checking for air filter clogs, changing the oil, and inspecting spark plugs, can keep performance optimal. If issues persist, further investigation into the ignition or fuel system may be required.