When it comes to maintaining a lawn mower, understanding the layout and function of its key control elements is crucial. These components ensure smooth operation, allowing the machine to navigate and respond to user input efficiently. Regular upkeep can prevent wear and extend the mower’s life, making it essential to familiarize oneself with the system’s structure and functionality.

Identifying and replacing faulty elements can save both time and money. Whether you are dealing with a mechanical issue or simply conducting routine checks, knowing how to interpret the configuration of these components can be a game changer. Through careful inspection, users can detect early signs of malfunction and address them before they lead to more significant problems.

Familiarity with the assembly enables faster troubleshooting, helping owners ensure the equipment performs at its best for years to come. Understanding the intricate relationships between each part allows for efficient repairs and adjustments, keeping the machine in top condition.

Understanding the Control Mechanism of Lawn Mower

The control system of a lawn mower plays a pivotal role in its performance, enabling precise movement and accurate direction changes. The functionality of this system relies on the efficient interaction between various mechanical components that guide the mower’s path. A clear understanding of how these elements work together ensures smooth operation and minimizes the risk of malfunctions during use.

Each part within the mechanism serves a unique purpose, whether it’s adjusting the angle of movement or maintaining stability. A failure in any of these components can lead to difficulty in maneuvering, affecting both the ease and quality of mowing. Regular inspection and maintenance of these crucial elements are vital to prevent premature wear and ensure the machinery operates at peak efficiency.

Knowing the structure and function of the system helps in identifying problems early on. When users are familiar with how each part contributes to overall performance, they can detect issues before they escalate, saving both time and money on repairs. Understanding the relationships between these mechanical components also aids in making informed decisions when it comes to replacements or adjustments.

Key Parts for Repair and Replacement

When it comes to maintaining or fixing a mower, identifying the right components is crucial for effective repairs. Several key elements work together to ensure smooth functionality and proper operation. Understanding which parts are most susceptible to wear and tear can help prioritize repairs and replacements, ensuring minimal downtime and optimal performance.

Common Components to Inspect

Control rods, linkages, and pivots are vital elements that often require attention. These components are responsible for transmitting motion and direction changes. Over time, they can become loose, corroded, or damaged, leading to reduced responsiveness. Regular inspection of these parts is essential to maintaining the mower’s ease of use.

When to Replace Key Elements

Worn-out belts, gears, and bushings can severely impact the efficiency of the machine. These parts endure constant stress and friction, which can cause them to deteriorate over time. Replacing these components before they fail completely can prevent more extensive damage and keep the mower operating smoothly.

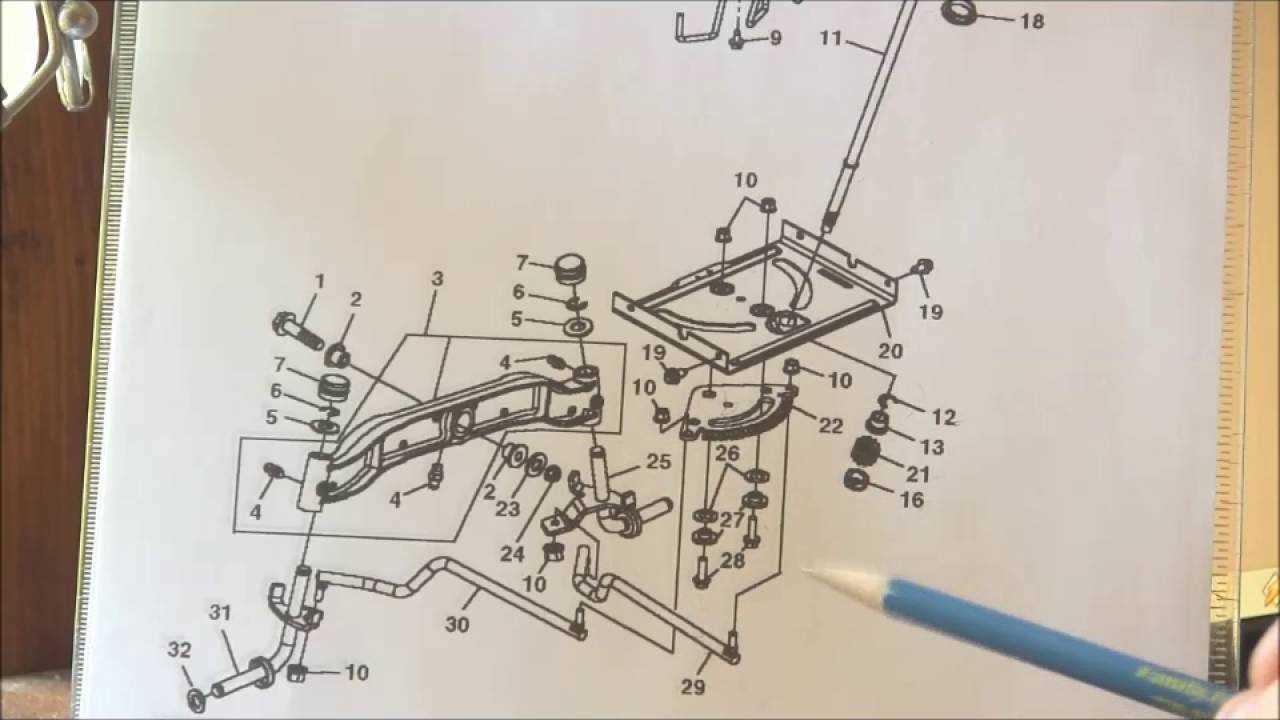

How to Interpret the Control System Layout

Understanding a machine’s control system layout is crucial for effective maintenance and repairs. These visual representations provide an overview of the components and their relationships, helping users identify key elements that affect performance. By interpreting these schematics correctly, you can pinpoint issues quickly and address them with precision.

Study the connections and flow of motion shown in the layout to grasp how different parts interact. Each line and symbol represents a connection or mechanism that plays a role in the machine’s movement. Recognizing these connections allows you to understand how adjustments to one component can impact others, ensuring a more efficient troubleshooting process.

Familiarize yourself with key symbols used in the layout. Manufacturers often use specific notations to represent different parts and functions. Knowing these symbols will help you navigate the schematic and interpret the information correctly, enabling you to make informed decisions when performing repairs or replacements.