Understanding the internal structure of your lawn equipment is essential for proper maintenance and repairs. Whether you’re a seasoned mechanic or a first-time user, familiarizing yourself with the mechanical layout ensures you can handle repairs effectively.

Exploring the machinery’s design offers insight into each component’s function, helping you identify areas that need attention. Using detailed technical illustrations aids in locating specific parts and their connections, making the process simpler.

With this knowledge, you can troubleshoot, replace worn-out components, and extend the life of your equipment. Learning how to interpret these visuals and diagrams will empower you to take control of your maintenance tasks confidently.

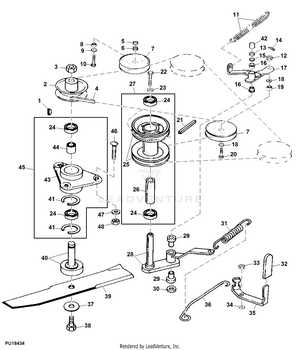

Understanding the Lawn Tractor Mechanism

The internal workings of a lawn mower play a crucial role in its efficiency and longevity. By understanding how each element operates, you gain the ability to perform better maintenance and ensure the machine runs smoothly. Recognizing the individual parts and their functions can help you pinpoint issues before they escalate into larger problems.

Each mechanical system is designed to serve a specific purpose, whether it’s powering the wheels or controlling the cutting deck. Familiarizing yourself with the layout and function of these systems is the first step in proper care and repair. When you can visualize how the pieces interact, you can troubleshoot more effectively and avoid costly mistakes.

By gaining a deeper understanding of how the equipment works, you’re better equipped to handle common issues such as belt tension, fluid levels, or engine performance. This knowledge is vital not only for repairs but also for enhancing the overall lifespan of your machine.

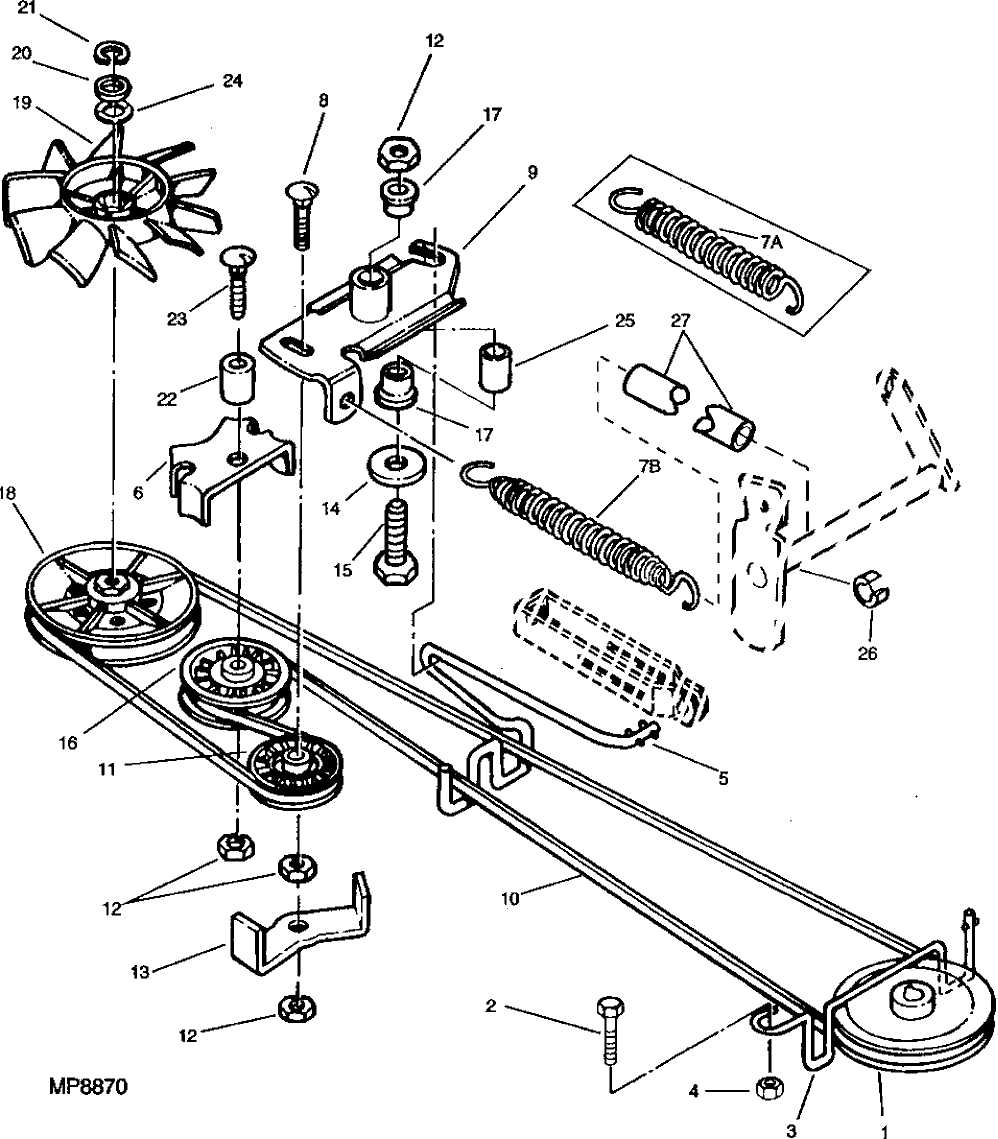

Key Components of the Hydrostatic Drive

The transmission system is essential for controlling movement and power in lawn equipment. The key to its functionality lies in the fluid-driven mechanism, which provides smooth, variable-speed operation without the need for complex gear shifting. Understanding the core elements that make up this system will help you maintain optimal performance and diagnose any issues that arise.

At the heart of the system is the hydraulic pump, which transfers power to the drive wheels. The pump is responsible for converting mechanical energy into hydraulic energy, enabling the machine to move. Another crucial component is the motor, which works in tandem with the pump to deliver the necessary force for motion.

Additionally, fluid management plays a significant role in the efficiency of the entire system. Regularly checking fluid levels and ensuring there are no leaks will prevent system failure and ensure a consistent performance over time. Proper maintenance of these core components ensures a longer lifespan for your equipment.

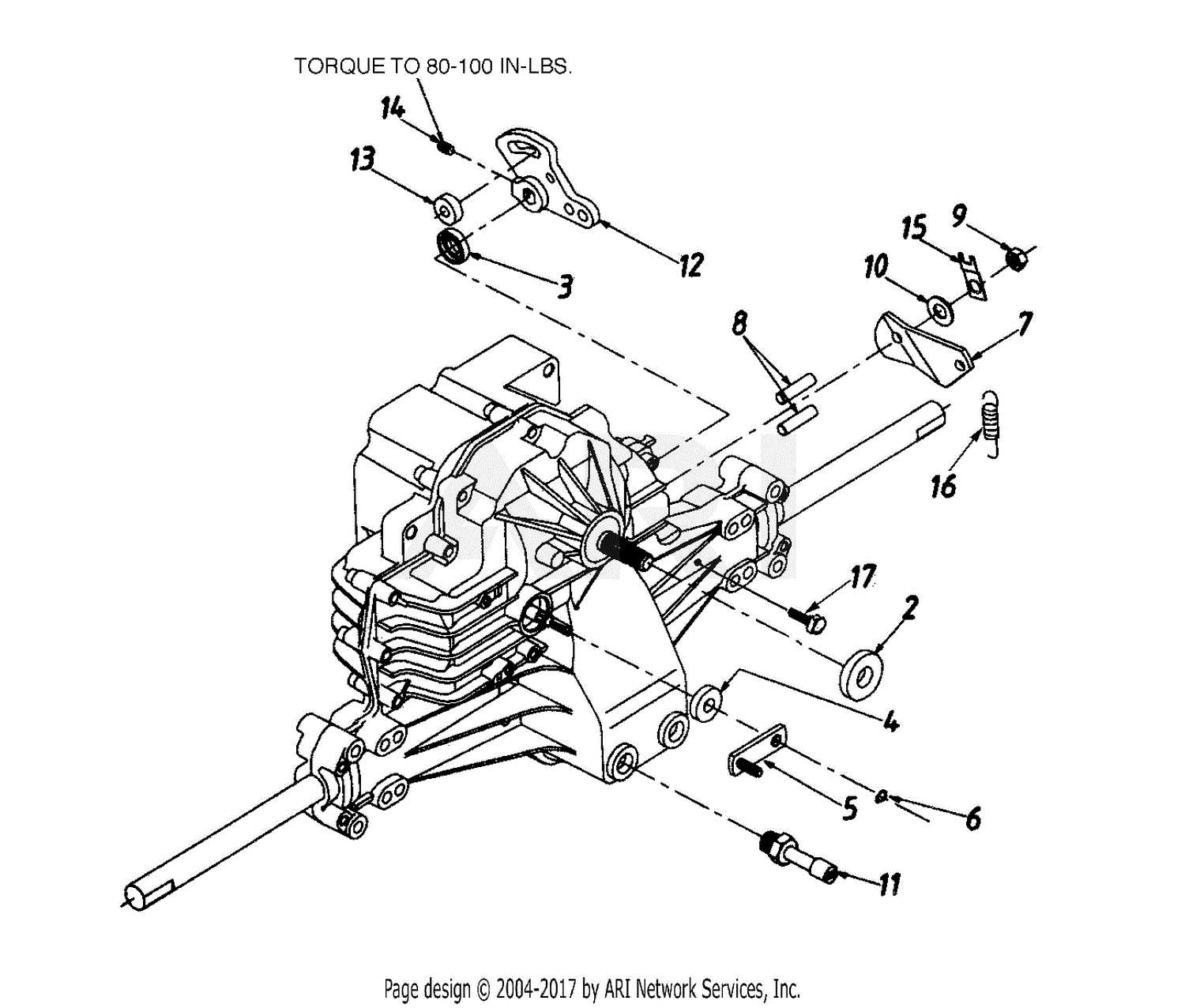

How to Use the Parts Diagram Effectively

Understanding how to read technical illustrations can greatly enhance your ability to troubleshoot and repair machinery. These visual aids offer a detailed view of the equipment’s internal components, allowing you to locate specific parts and understand their functions. Properly interpreting these images helps in identifying the right pieces when making replacements or adjustments.

Start by familiarizing yourself with the overall layout of the system. Pay attention to labels and connections, which indicate how parts interact with each other. Understanding the relationship between different components will make the repair process more intuitive, preventing mistakes and saving time.

When using technical visuals, focus on key areas like assembly instructions, part numbers, and the flow of fluids or energy through the system. These elements will guide you in both disassembling and reassembling equipment correctly, ensuring smooth operation and longevity of your machinery.