Every mechanical device relies on a set of essential components to operate smoothly. Knowing how these elements fit together and function is critical for proper maintenance and troubleshooting. Whether you’re a novice or an experienced user, understanding the internal workings can enhance the overall performance of your equipment.

In this section, we will explore the intricate layout of various key elements within the system. By analyzing how each piece contributes to the machine’s functionality, you can better assess any potential issues and make informed decisions about repairs or upgrades.

Having a clear understanding of these fundamental parts allows for quicker identification of problems and ensures that each component performs optimally. From simple wear-and-tear issues to more complex failures, recognizing the role of each element is crucial for efficient management.

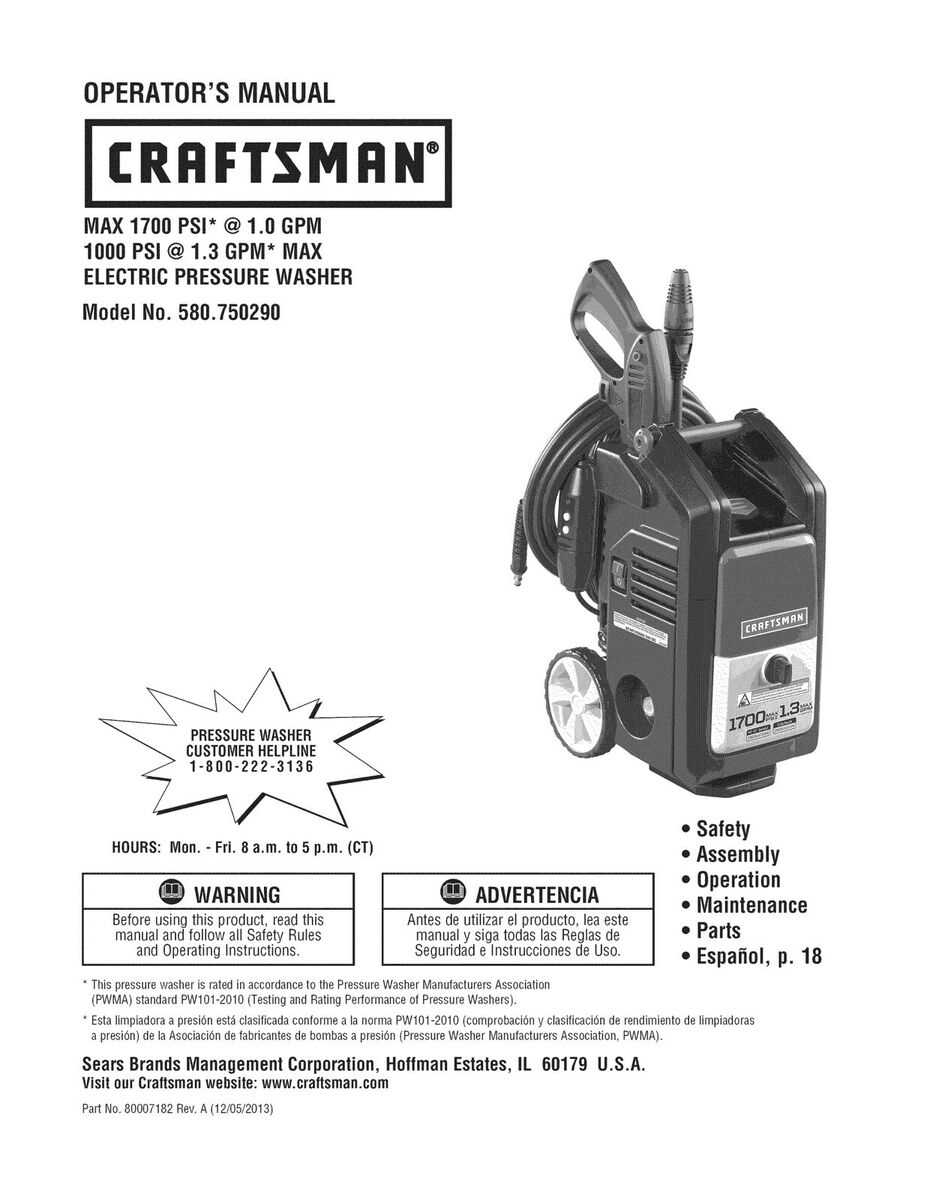

Understanding Key Components of the Cleaning Equipment

To operate any high-performance cleaning device effectively, it is essential to have a solid understanding of its internal mechanisms. Recognizing how each element contributes to the overall system will ensure proper functionality and smooth operation. Identifying the roles of each component helps users manage their equipment more efficiently and address issues promptly.

In this section, we will delve into the various key components that make up this device. From the motor to the nozzles, each part plays a vital role in the overall performance. By understanding how these elements interact, users can make more informed decisions about maintenance and repairs.

Familiarity with these critical components helps in troubleshooting and ensures that the machine remains in peak condition for longer periods. Regular checks and proper care can significantly enhance the device’s longevity and effectiveness, ensuring it meets cleaning needs without interruptions.

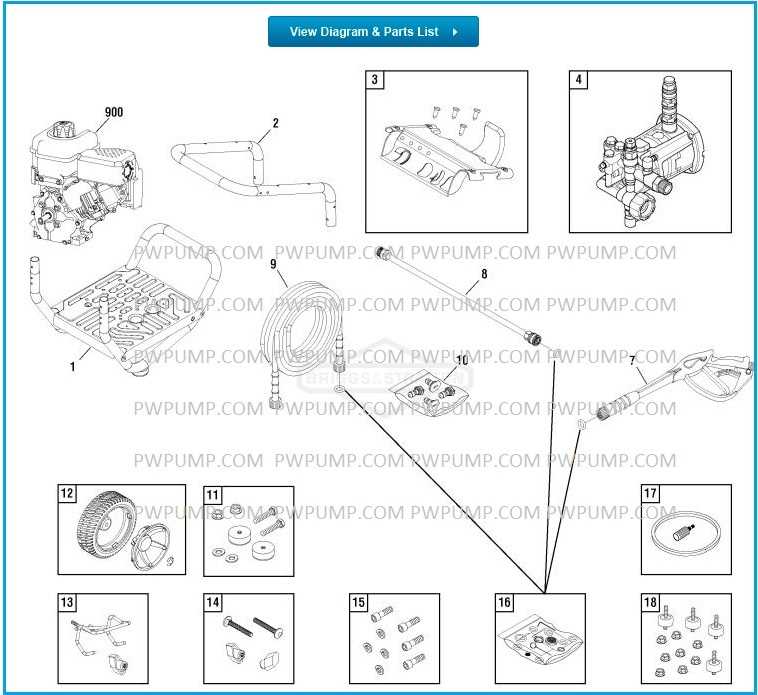

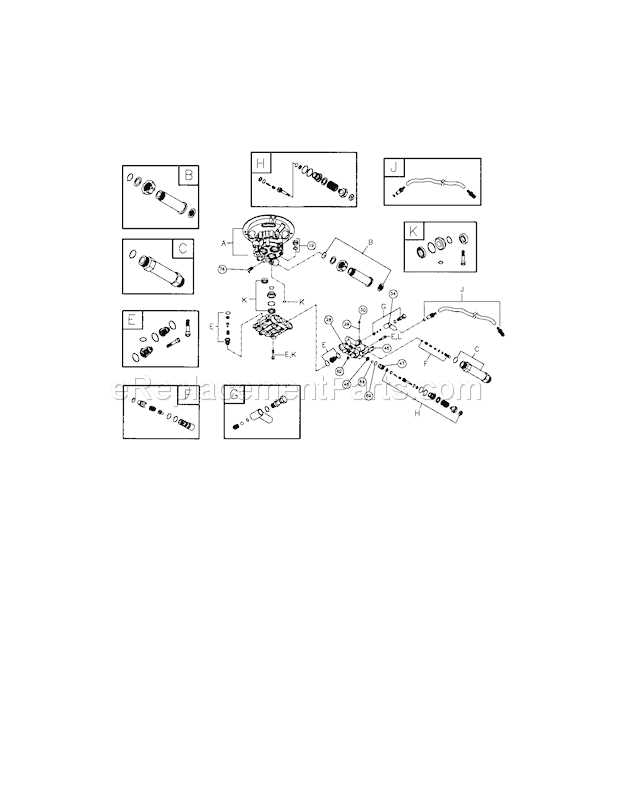

How to Identify Key Elements in Schematics

Understanding how to interpret schematics is essential for identifying the different components of any mechanical system. These visual representations provide a clear layout of the device’s internal structures, allowing users to pinpoint specific parts and their connections. Knowing how to read these diagrams efficiently ensures you can locate any component that may require attention or replacement.

To begin, focus on the labels and markings that indicate each part’s function within the system. These guides often use symbols or color coding to distinguish between various elements, such as valves, motors, and hoses. Familiarizing yourself with these symbols will allow for quick identification and a more thorough understanding of how the machine operates.

Once you are accustomed to the common symbols and their corresponding components, you’ll be able to trace the flow of energy or fluid through the system. This knowledge is invaluable when diagnosing issues or making adjustments. Clear comprehension of the schematic layout empowers users to maintain and repair equipment with confidence and accuracy.

Common Issues and Component Replacements

Mechanical devices often experience wear and tear over time, leading to common malfunctions. Identifying these issues early on can help prevent further damage and ensure the equipment remains functional. Recognizing signs of failure and knowing how to replace faulty elements are key to maintaining optimal performance.

Frequent Failures and Troubleshooting

Common issues include worn-out seals, clogged filters, or malfunctioning motors. These problems can lead to decreased efficiency or complete system failure. Regularly inspecting these areas helps identify potential failures before they affect the overall operation. Early detection ensures the equipment runs smoothly, minimizing downtime.

How to Replace Malfunctioning Components

Once a faulty part is identified, it’s essential to replace it promptly. Many components can be easily swapped out with the right tools and knowledge. Be sure to consult a schematic or user manual to locate the exact position of the part. Ensuring the correct replacement part is used will help maintain the integrity of the system and prevent future issues.