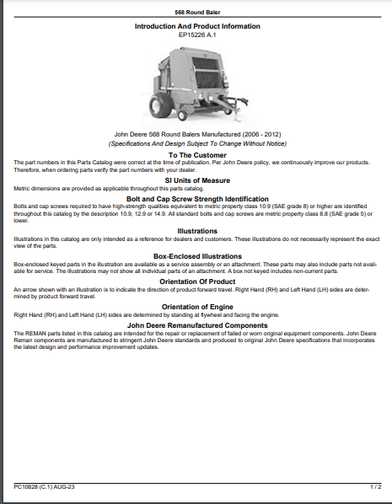

Proper maintenance of agricultural machinery ensures its longevity and optimal performance. Understanding the structure and components of these machines is crucial for efficient repairs and regular upkeep. A clear understanding of how each element functions together can prevent costly breakdowns and downtime.

For farmers and machine operators, being familiar with the layout and function of key mechanical parts is vital. Having access to a well-organized visual guide simplifies identifying issues, ordering replacement parts, and completing necessary repairs without delay. By maintaining a strong grasp of these connections, operators can enhance machine reliability during the busiest seasons.

This section offers a comprehensive look at the essential parts of your machinery, providing you with all the necessary details to keep it running smoothly for years to come.

Understanding Key Machinery Components

Every piece of heavy agricultural equipment relies on an intricate system of interconnected elements, each playing a vital role in ensuring smooth operation. From the primary mechanisms that drive motion to the smaller, more specialized components, understanding how they work together is essential for effective maintenance and repairs.

Identifying each part’s function helps operators diagnose problems more quickly and accurately. This knowledge allows for faster identification of wear and tear, making it easier to replace faulty components before they cause significant damage or downtime.

With a clear overview of the main mechanical systems and their respective roles, users can ensure their machinery remains in top condition, ready to handle demanding tasks during peak seasons. Properly maintaining the equipment not only extends its life but also enhances its performance and efficiency.

How to Identify Key Baler Components

Identifying the main elements of a complex piece of agricultural machinery is crucial for effective maintenance and repair. Each section of the machine has a specific function, and understanding these functions helps ensure smoother operation and faster troubleshooting when issues arise.

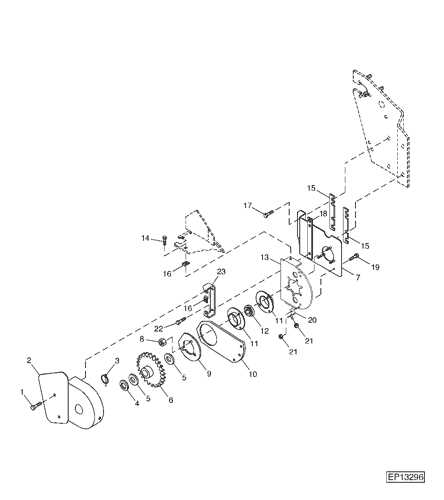

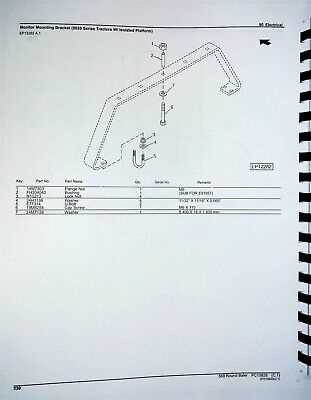

Recognizing Major Mechanical Systems

The first step in identifying critical components is to familiarize yourself with the major systems involved in the machine’s operation. This includes the drive system, which powers the machine, and the feeding mechanism that helps load material into the machine. These systems are integral to the overall performance, and understanding how they work together is key to identifying problems quickly.

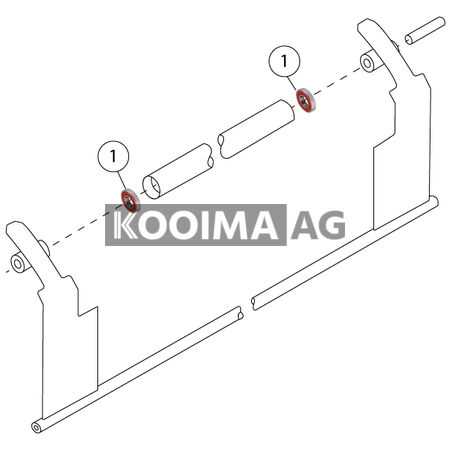

Understanding Smaller Parts and Accessories

In addition to the major systems, smaller parts such as sensors, hydraulic components, and belts also play vital roles. These parts can wear out over time, leading to malfunctions if not properly maintained. Identifying the location and function of each component allows operators to monitor wear and act proactively before serious issues develop.

Tips for Maintaining Your Baler Parts

Regular maintenance is essential for extending the life and improving the efficiency of your agricultural machinery. By keeping all the essential components in optimal condition, you can prevent unexpected breakdowns and reduce repair costs. Proper care ensures that every part of the system performs as expected, even during the busiest harvests.

Regular Cleaning and Inspection

One of the simplest yet most effective maintenance tasks is routine cleaning. Dust, dirt, and debris can accumulate in key areas and cause wear or malfunctions over time. Regularly inspecting components for signs of wear, rust, or dirt buildup will help identify potential issues early on, preventing more serious damage later.

Lubrication and Tightening

Ensure that moving parts are properly lubricated to reduce friction and prevent unnecessary wear. This includes greasing joints, bearings, and other key mechanical elements. Additionally, check for loose bolts, screws, or fasteners, as these can lead to equipment failure if left unchecked. Regular tightening and re-lubrication will keep the machine running smoothly.