When it comes to maintaining and repairing small engines, knowing the layout of the internal components is crucial. A clear understanding of the parts involved can greatly enhance your ability to troubleshoot issues and perform necessary repairs. This section focuses on the essential parts of small engines and provides a closer look at their arrangement and function.

Identifying the core elements of any engine is the first step in ensuring it runs smoothly. Each piece plays a specific role, and recognizing how they interact is key to effective maintenance. Whether you’re replacing worn-out components or addressing performance issues, having a visual representation of the engine’s structure helps in making informed decisions.

Accurate knowledge of these components not only aids in repairs but also in regular upkeep. Regular inspections and understanding how different parts work together can prevent unnecessary breakdowns and extend the life of the engine. This guide provides detailed insights that can assist both beginners and seasoned professionals in navigating engine repairs with ease.

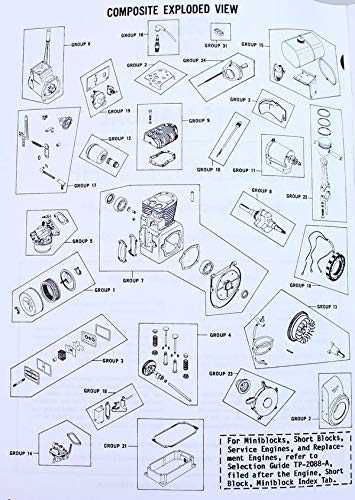

Kohler CH270 Engine Component Breakdown

Understanding the internal structure of an engine is essential for proper maintenance and troubleshooting. Each engine consists of several critical elements, each playing a specific role in ensuring smooth operation. A clear grasp of these components and their arrangement can help identify problems early and prevent costly repairs.

The engine’s core includes essential items such as the crankshaft, pistons, and cylinder head, which work together to convert fuel into mechanical energy. The fuel system, ignition system, and exhaust components also play crucial roles in maintaining performance and efficiency. By familiarizing yourself with the function of each part, you can approach repairs and upgrades with greater confidence.

Knowing the placement and connection of various elements makes it easier to spot signs of wear and tear. A detailed understanding of the engine’s design also helps in optimizing performance, ensuring that each part operates at its best. Regular checks and maintenance can extend the engine’s lifespan and improve overall reliability.

Understanding the Kohler CH270 Parts Layout

Proper knowledge of an engine’s internal layout is fundamental for efficient maintenance and repair. Recognizing where each component fits and how it interacts with others is essential for identifying faults and performing necessary replacements. This section delves into the organization of key engine elements, offering insight into their respective locations and functions.

Core Engine Components

The main engine elements include the piston assembly, crankshaft, and cylinder head. These parts work together to generate power, and understanding their layout helps diagnose mechanical issues that may arise during operation. For instance, the alignment of the piston and crankshaft plays a crucial role in the engine’s overall performance, while the cylinder head ensures proper compression and exhaust flow.

Supporting Systems and Components

In addition to the core components, other systems such as the fuel delivery system, ignition system, and cooling mechanisms contribute to the engine’s function. Each of these subsystems relies on precise placement to ensure seamless interaction with the main engine parts. Knowing the configuration of these supporting components can be immensely helpful when troubleshooting performance issues or conducting preventive maintenance.

Key Components for Kohler CH270 Maintenance

Regular upkeep of an engine requires a close look at its most important components. These critical parts play a significant role in maintaining performance and preventing breakdowns. Understanding which elements to focus on during maintenance ensures that the engine runs smoothly and lasts longer.

Fuel system is one of the first areas to inspect. A clean fuel filter, properly functioning carburetor, and secure fuel lines are essential for smooth engine operation. Any issues in this system can lead to poor performance or engine failure, so regular checks and cleaning are crucial.

Ignition system components such as the spark plug and ignition coil should also be regularly maintained. These parts are responsible for the engine’s start-up and consistent operation. Over time, the spark plug may accumulate carbon deposits, affecting ignition efficiency, which is why it is important to replace it as needed.

The cooling system, including the air filter and cooling fins, helps regulate the engine’s temperature and prevent overheating. A clogged air filter or blocked cooling fins can lead to overheating and damage, so ensuring they are clear and functioning properly is essential for the engine’s longevity.