When maintaining or repairing a vehicle, having a clear reference of its components is essential. A well-organized visual representation can significantly simplify the process of identifying and fixing issues, ensuring that each part is correctly understood and addressed. These guides serve as an invaluable tool for anyone looking to enhance their technical skills or perform maintenance tasks effectively.

Accurate identification of individual elements is crucial for proper assembly and function. By referring to a detailed chart, users can avoid costly mistakes and expedite the repair process. Each part, whether small or large, has its designated place and role, and understanding these relationships is key to achieving optimal performance.

Using a reference layout allows for a better understanding of the overall system. With this knowledge, users can approach repairs with confidence, knowing exactly where each piece fits and how to troubleshoot any potential malfunctions. This kind of preparation lays the groundwork for efficient, effective maintenance work.

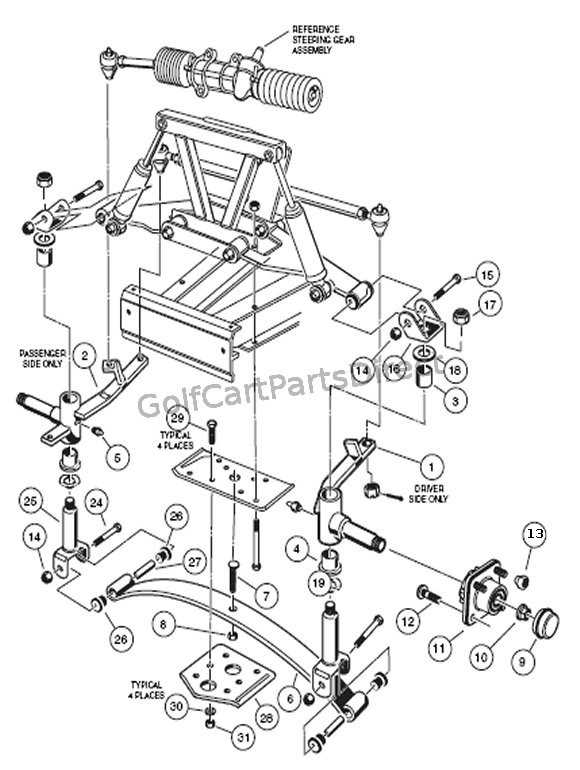

Understanding the Vehicle Component Layout

In any mechanical system, understanding the arrangement of its individual elements is crucial for effective maintenance and repair. A visual reference helps to break down complex systems into more manageable sections, making it easier to locate specific components, understand their function, and ensure proper assembly. This clarity can significantly improve the speed and accuracy of troubleshooting and repairs.

Identifying Key Components

Each element in the layout serves a specific function within the overall system. Whether it’s for power transmission, control, or safety, understanding the role of each part is vital. A good reference chart typically highlights all the main components and their interconnections, allowing users to quickly identify what needs attention. This knowledge is particularly useful for routine maintenance, as well as for addressing unexpected issues that may arise during use.

Using the Layout for Troubleshooting

When issues arise, having a clear understanding of where each part is located can make troubleshooting much more efficient. By following the visual guide, technicians can pinpoint malfunctioning elements quickly, without wasting time searching for the problem. This method also aids in understanding the relationship between different parts, helping to diagnose issues that might be affecting more than one component simultaneously.

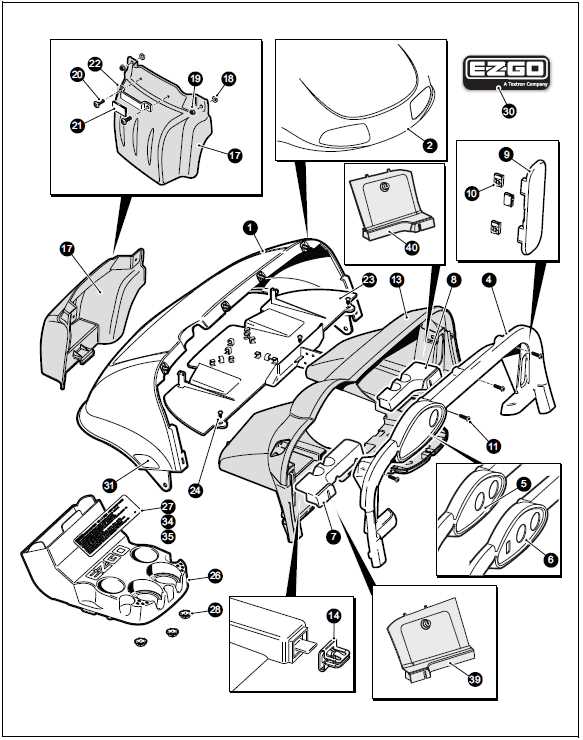

Identifying Key Components for Maintenance

Proper maintenance begins with understanding the essential elements that make up a system. Identifying these components ensures that technicians can focus their efforts on areas most prone to wear and tear. A clear understanding of the structure helps prioritize checks, repairs, and replacements, leading to more efficient and effective upkeep.

Recognizing Critical System Elements

Some components are fundamental to the overall functionality of the vehicle. These parts are responsible for power distribution, safety, and operational control. By recognizing the key elements, such as the motor, battery, and suspension, users can focus on maintaining the most important areas first. Proper care of these primary parts prevents major malfunctions and prolongs the lifespan of the entire system.

Routine Maintenance for Longevity

Regular inspection and maintenance of crucial components can prevent small issues from becoming costly problems. Understanding the specific needs of each component allows for timely interventions, such as cleaning, lubricating, or replacing parts. This proactive approach ensures that the vehicle remains in optimal condition, minimizing downtime and improving overall performance.

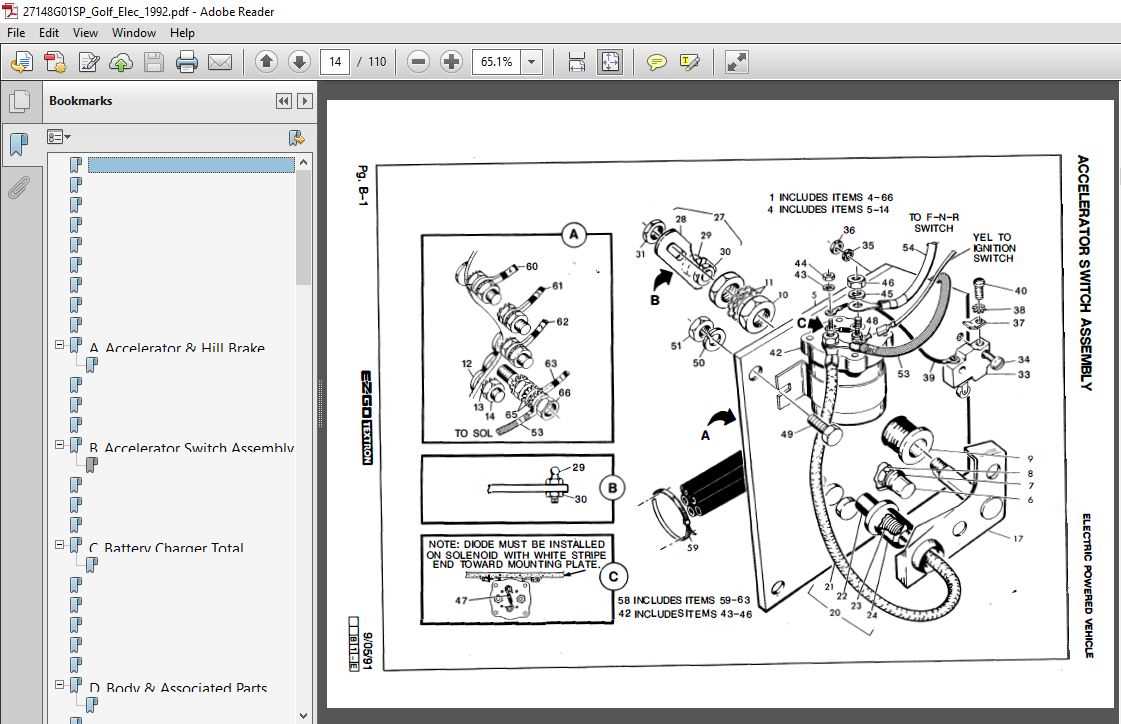

How to Use the Layout for Repairs

When it comes to making repairs, a well-structured visual guide can be a powerful tool. By providing a clear reference of the system’s components and their connections, it becomes easier to identify problems and plan the necessary steps for fixing them. Knowing how to effectively use such a guide streamlines the process, helping you tackle issues quickly and with confidence.

Locating the Problem Area

The first step in using a visual reference for repairs is to pinpoint the area where the issue is occurring. The guide will typically provide a breakdown of the system, making it simple to find specific components based on their function and location. Once you’ve identified the problematic section, you can focus your attention on the parts that need inspection or replacement.

Understanding Component Interactions

A good reference layout not only shows the parts but also highlights their interconnections. Understanding how components interact with each other is key when making repairs, as many issues may stem from one malfunctioning element affecting others. By following the guide?s connections, you can more easily isolate the root cause and fix the problem without causing further damage.