When it comes to maintaining and repairing your lawn care equipment, understanding its internal structure is key to efficient operation. Knowing where each element fits and how they interact can make a significant difference when troubleshooting or upgrading your machine. A clear understanding of how the various parts are organized helps ensure smooth performance and longevity.

Each model of lawn mowers comes with a unique setup that can sometimes be difficult to navigate without proper visual aids. By examining the layout and configuration of its essential components, you can easily identify areas that need attention, replacement, or cleaning. This insight will not only save you time but also protect your equipment from unnecessary wear and tear.

Familiarizing yourself with the inner workings of your machine is crucial. It allows for precise adjustments and ensures you have the correct parts on hand when needed. Whether you are tackling a simple maintenance task or preparing for more involved repairs, knowing the exact layout makes the process straightforward and efficient.

Understanding the Lawn Mower’s Essential Components

Each lawn mower has a set of key elements that work together to ensure proper function. These components, when correctly understood, enable easier maintenance and more efficient repairs. Identifying where each piece fits within the overall structure can help in both troubleshooting issues and enhancing the mower’s overall performance. Understanding how these parts interact with one another is the foundation of effective care and long-lasting reliability.

The primary sections of any mower include the driving mechanism, the cutting system, and the control features, each performing a vital role in the machine’s operation. The cutting system, for instance, involves elements that directly affect the precision and quality of your lawn’s appearance, while the driving mechanism ensures mobility and easy maneuverability.

Knowing how to identify and access these crucial elements simplifies the process of routine checks and part replacements. Proper maintenance can extend the lifespan of your equipment, improve its efficiency, and help avoid costly repairs down the road. Whether you’re dealing with wear and tear or performing preventive measures, understanding the layout and function of each component is essential.

How to Identify Key Components on Your Lawn Mower

Identifying the essential elements of your lawn mower is crucial for efficient maintenance and repairs. Recognizing the location and function of each component helps streamline the process when it’s time to replace or service them. Visual aids, like clear labeling and detailed schematics, make it easier to pinpoint parts that may require attention or adjustment.

The first step in identifying the parts of your mower is understanding the general layout. Start by familiarizing yourself with the main sections of the machine, such as the engine area, the cutting mechanism, and the transmission. Each section houses several components that perform specific functions, and knowing where to find them is key to effective repairs.

Once you have a good grasp of the overall structure, focus on the smaller components. Pay attention to wear marks, rust, or any unusual noises during operation, as these often signal that certain elements are in need of replacement. Referring to visual diagrams and parts catalogs can further assist in making sure you have the right replacement pieces and tools for the job.

Replacing and Maintaining Lawn Mower Components

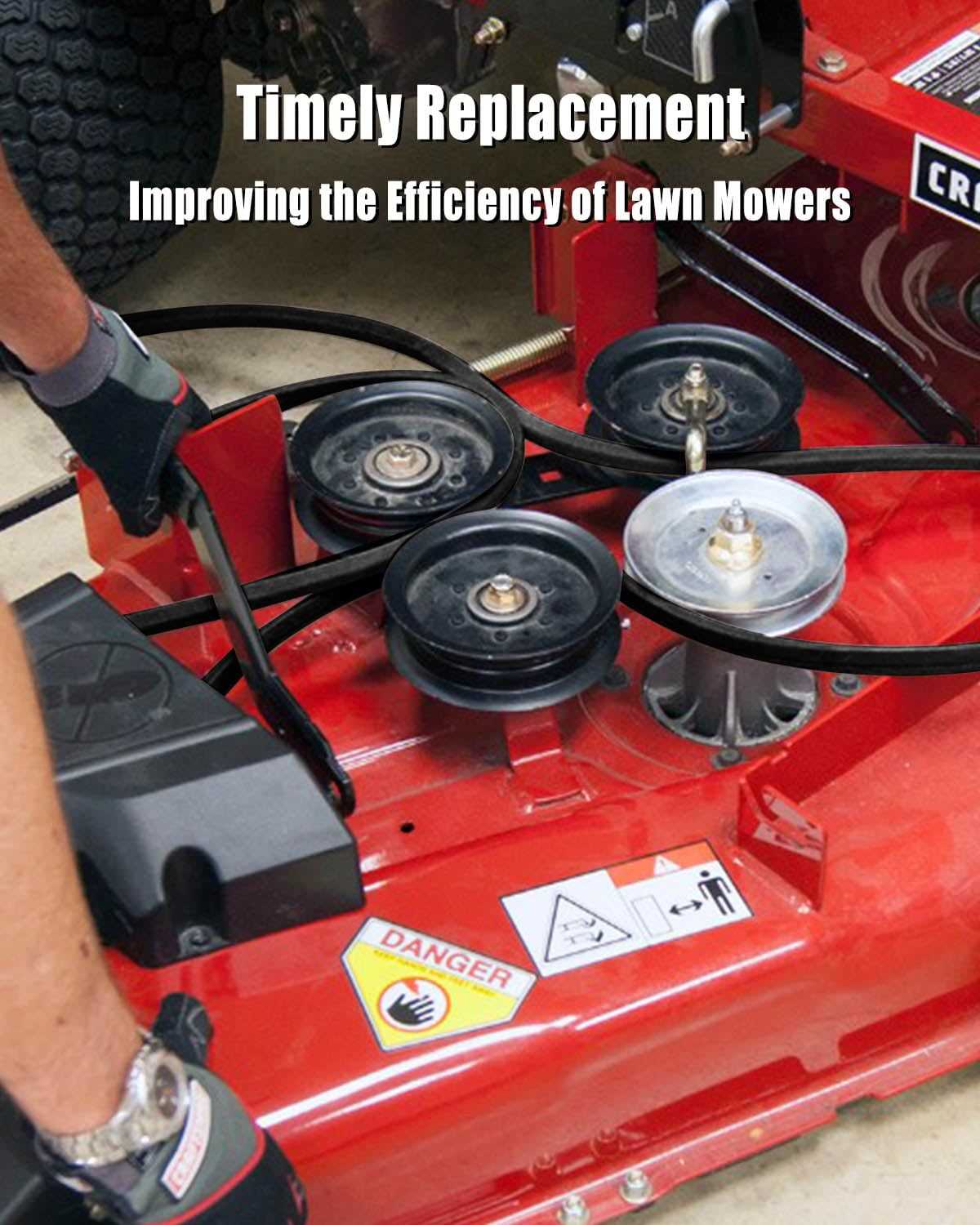

Proper maintenance and timely replacement of worn-out elements are essential for keeping your lawn care equipment running smoothly. Regularly inspecting key components and addressing issues before they escalate will prolong the life of the machine and ensure peak performance. By understanding when and how to replace specific parts, you can avoid costly repairs and prevent unnecessary downtime.

Routine Maintenance for Optimal Performance

Start by checking critical elements such as the blades, belts, and wheels. These components experience the most wear and tear during use. Ensure the cutting blades are sharp, free from cracks, and properly aligned. Belts should be checked for signs of fraying or stretching, while wheels must rotate freely without resistance. Regular lubrication and cleaning after each use will help prevent buildup and ensure smooth operation.

When to Replace Worn-Out Components

Over time, even the most durable parts will need replacement. Keep an eye out for irregularities in performance, such as uneven cutting or difficulty in starting. When parts such as belts or the cutting mechanism begin to show signs of damage, it’s important to replace them promptly. This will not only maintain the efficiency of your machine but also help avoid damage to other, more expensive components. Refer to the manual for guidance on the recommended service intervals and replacement schedules for each part.