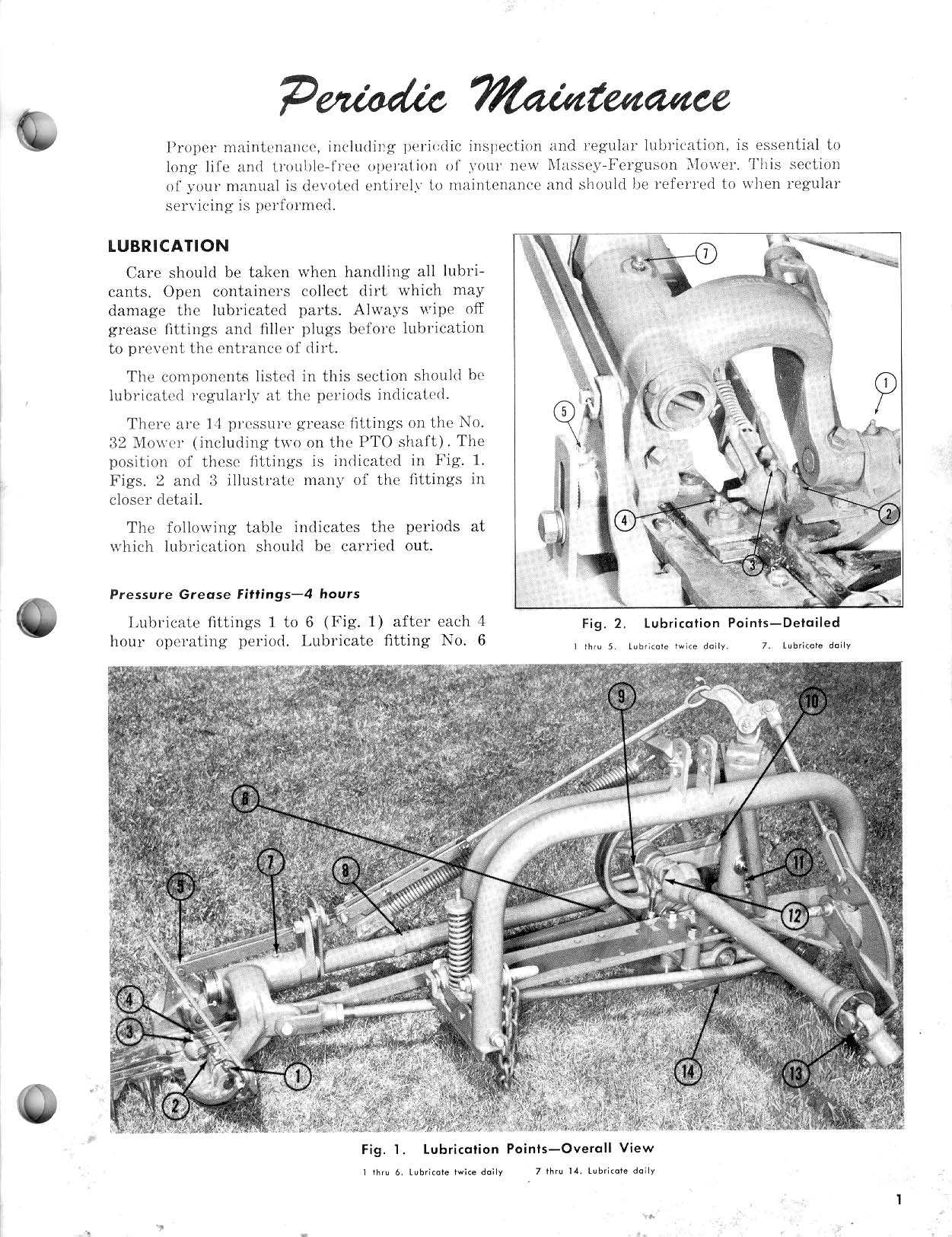

Proper maintenance of agricultural machinery is essential for ensuring long-lasting performance and efficiency. A clear understanding of the individual elements that make up the equipment is crucial for any operator or technician. This knowledge helps identify issues early, facilitate repairs, and streamline replacements when necessary.

In this guide, we will explore the various components of a popular model, offering insight into their functions and how to identify them. Whether you are a seasoned professional or a newcomer to machinery upkeep, knowing how to interpret the structure and function of key elements can save both time and resources.

Familiarity with the construction and layout of these machines allows for more effective diagnostics and smoother maintenance processes. By the end of this article, you will have a better understanding of the main components and how to navigate through a detailed assembly overview.

Understanding Massey Ferguson 41 Mower Parts

When working with agricultural equipment, a thorough understanding of its key components is essential for effective maintenance and troubleshooting. Each element serves a specific purpose, and knowing how they interact can make a significant difference in operation and repair efficiency. This section will guide you through the critical parts of the machine and explain their functions, helping you better navigate the upkeep of your equipment.

Key Components of the Machine

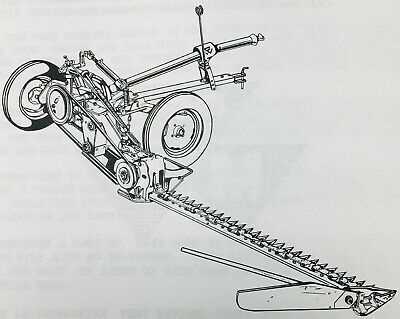

The essential elements of the machine include various mechanical and structural components that ensure its proper functioning. These parts work together to facilitate smooth operation, from cutting to maneuvering the unit. Recognizing the role of each piece is important for maintaining optimal performance. Common parts include the cutting mechanism, drive system, and frame, all of which contribute to the overall efficiency of the machine.

Maintaining and Replacing Components

Regular maintenance and timely replacement of worn-out parts are crucial for extending the lifespan of your equipment. Familiarizing yourself with the components allows for quicker identification of issues and easier replacement when necessary. Keeping spare parts on hand and knowing how to properly install them ensures that the machine remains in good working condition, reducing downtime and enhancing productivity.

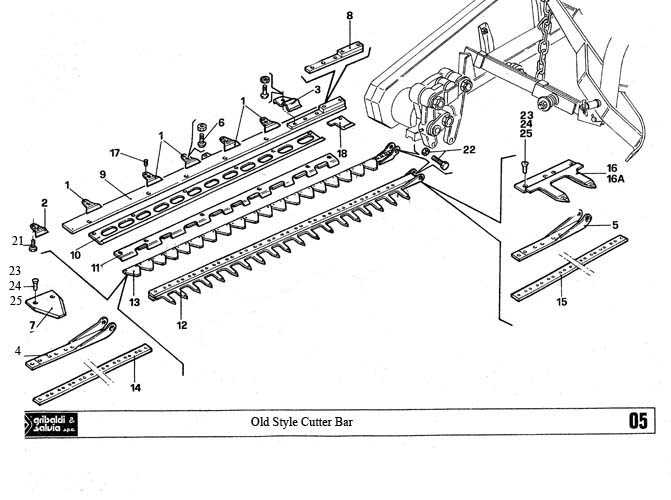

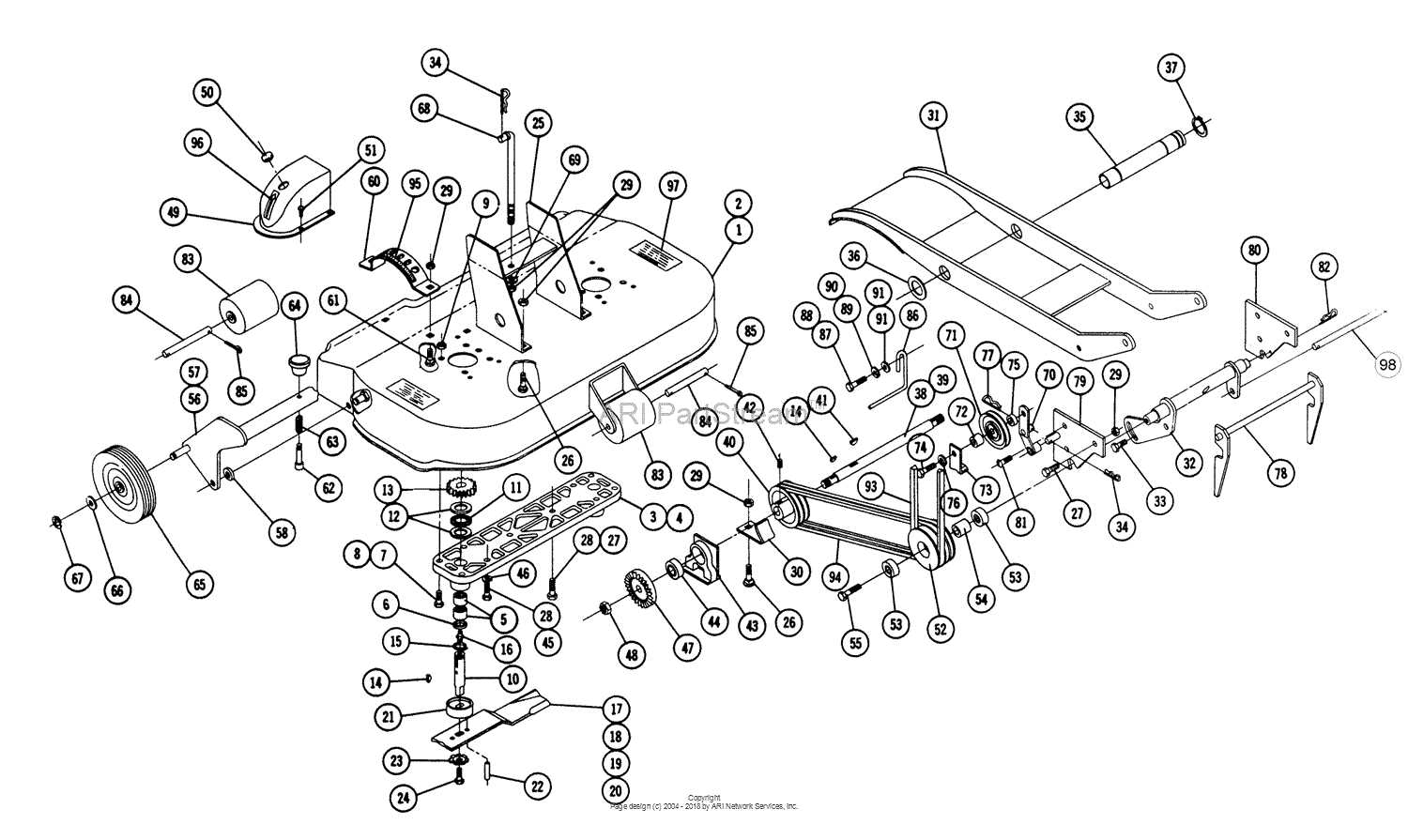

How to Read a Sickle Mower Diagram

Understanding technical illustrations is a critical skill when it comes to equipment maintenance and repair. These visual guides help you identify individual elements and their relationships within the entire system. By becoming familiar with how to interpret these diagrams, you can quickly locate the necessary parts and follow accurate instructions for assembly or troubleshooting.

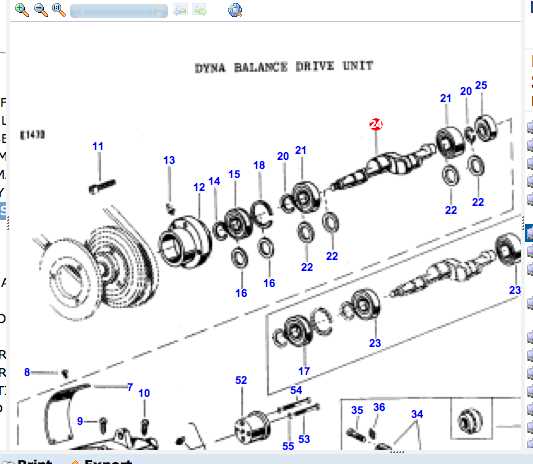

Identifying Key Components

In a typical schematic, various components are represented by symbols or labels that correspond to specific physical elements. It is important to recognize these symbols and understand what they signify. Some of the most common representations include mechanical parts, connectors, and fasteners, which are usually marked with numbers or letters for easy reference.

Following the Assembly Layout

Once you familiarize yourself with the components, you can start following the assembly layout. These diagrams usually present the equipment in a step-by-step manner, showing how each part fits into the larger system. Pay attention to the flow of connections, as this will help you identify the sequence of assembly and pinpoint potential issues during disassembly or reassembly. Additionally, understanding the orientation of the parts and how they interact is essential for proper functioning.

Common Replacement Parts for MF 41 Mower

Regular wear and tear can cause certain elements of your agricultural equipment to become worn or damaged, requiring replacement to maintain performance. Knowing which components are most commonly replaced allows for quicker maintenance and ensures that your machine remains in optimal working condition. This section highlights some of the most frequently replaced components for your unit, helping you stay prepared for any necessary repairs.

Blades and Cutting Mechanisms

One of the most commonly replaced elements in any cutting equipment is the cutting mechanism. Over time, blades become dull or damaged from frequent use. Regularly checking their condition and replacing them when necessary ensures clean and efficient operation. Blades are available in various shapes and sizes, so it’s important to choose the right ones based on your model’s specifications.

Drive Belts and Tensioners

Drive belts and tensioners are essential for transmitting power from the engine to the moving parts. These components can stretch, wear out, or become damaged with continuous use. Inspecting them regularly and replacing them when signs of wear appear can prevent malfunction and improve the overall efficiency of the system.