For any equipment owner, understanding the internal components is crucial for efficient maintenance and repairs. Properly identifying and replacing damaged elements can extend the life of your machine and improve its performance. This section provides a clear guide to help you navigate the intricate network of parts, ensuring that each piece functions optimally.

When dealing with mechanical tools, knowing where each component fits and how it operates is essential. A comprehensive visual map allows users to pinpoint specific areas that may require attention. By following the instructions and utilizing a reliable reference, you can tackle common issues with confidence and restore your equipment to peak condition.

Accurate identification of worn-out parts is key to maintaining the overall health of the machine. In many cases, replacing a small element can prevent larger problems down the road. Having a detailed reference on hand makes it easier to troubleshoot and perform repairs efficiently, saving both time and money.

Understanding Key Components of Lawn Equipment

Knowing the different components of your lawn care machine is essential for effective upkeep and performance. Each element plays a specific role in ensuring smooth operation, and understanding their functions can prevent unnecessary damage. This section will break down the critical components, highlighting how they contribute to the overall functioning of the machine.

Main Operational Elements

The core elements responsible for the primary functions of the machine include the engine, drive system, and cutting mechanism. Each part is interconnected, working together to provide efficient movement and cutting. Regular inspection and maintenance of these key components can significantly enhance the longevity of your machine and reduce the likelihood of breakdowns.

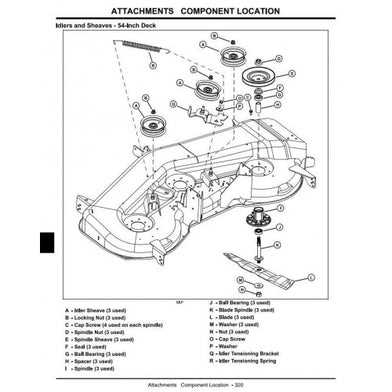

Supporting Components and Accessories

In addition to the main components, various supporting parts such as belts, springs, and control levers are crucial for fine-tuning the performance of the equipment. These smaller yet important elements ensure that the machine operates at its best and remains responsive to your commands. Proper knowledge of these supporting pieces will help identify when replacements or adjustments are necessary.

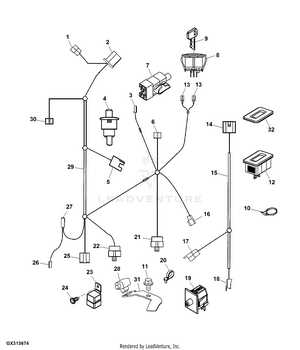

How to Use the Visual Reference Effectively

Using a detailed visual guide is one of the best ways to identify and locate individual components in any mechanical system. This reference tool helps you pinpoint specific parts, making it easier to perform repairs and maintenance tasks. By following a few simple steps, you can ensure that you use this guide efficiently and accurately, saving time and preventing mistakes.

Identifying Components with Ease

To begin, take note of the clearly marked sections within the guide. These labels are designed to highlight the main components and their relationships to one another. By focusing on the area that requires attention, you can easily find the corresponding part and understand its function in the system. This approach simplifies the process of diagnosing problems and streamlines your repair efforts.

Using the Guide for Replacements and Adjustments

Once you’ve located the damaged or worn-out component, the visual guide allows you to quickly identify the part number and relevant specifications. This makes the process of ordering a replacement much easier, ensuring that you get the correct part the first time. Additionally, the guide helps in adjusting or fine-tuning components, as it shows the proper alignment and configuration needed for optimal performance.

Common Issues and Replacement Components for Lawn Equipment

Like any mechanical system, your lawn equipment can experience wear and tear over time, leading to common malfunctions. Understanding these issues and knowing which elements to replace can help you avoid costly repairs and keep the machine running smoothly. This section will cover some of the most frequent problems encountered, as well as the components that are typically replaced to restore functionality.

Engine Overheating is one of the most common issues in outdoor machinery. This can result from a variety of causes, including a clogged air filter, insufficient oil levels, or a damaged cooling system. Regular checks of the engine and timely replacement of air filters and oil can help prevent overheating and extend the life of the equipment.

Drive Belt Wear is another frequent issue, especially in machines that have been used extensively. Over time, the drive belt can lose its tension or develop cracks, causing the machine to lose power or fail to function altogether. Replacing the drive belt promptly can prevent further damage to the system and maintain the equipment’s efficiency.

Cutting Mechanism Malfunctions can occur when the blades become dull or the system is misaligned. Keeping the cutting blades sharp and properly aligned is crucial for optimal performance. When necessary, replacing worn-out blades or adjusting the alignment will help maintain a clean and even cut.