When working with farm machinery, having a clear understanding of its key components is essential for proper maintenance and repair. Knowing where each part fits and how it interacts with others can save both time and money. This guide will help you navigate the complex system of tractor elements and their relationships.

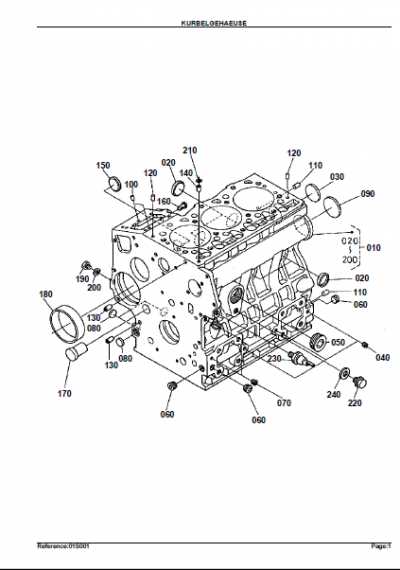

Proper identification of individual pieces is crucial for troubleshooting common mechanical issues. Whether you are performing routine maintenance or fixing a malfunction, understanding the layout of your equipment ensures that replacements are done accurately and efficiently. A well-organized view of the tractor’s internal structure offers clarity during every repair task.

For those new to the mechanics of such machinery, exploring its detailed structure provides confidence and understanding. Visual aids can make all the difference, enabling you to locate parts quickly and avoid unnecessary errors during repairs. The breakdown of each element is a critical resource for both novices and experienced operators alike.

Understanding the Tractor Component Breakdown

Efficiently maintaining and repairing farm machinery requires a clear understanding of how its individual elements are organized and interact with one another. A visual representation of the mechanical layout simplifies this process, enabling users to identify key sections and perform repairs with confidence. By familiarizing yourself with the structure of your equipment, you ensure that every job, from basic upkeep to more complex fixes, is completed correctly.

Key Sections and Their Functionality

Each major section of a tractor plays a vital role in its overall function, from the engine to the transmission system. Understanding how these components are linked together helps you troubleshoot issues more effectively. For example, recognizing the location of the fuel system in relation to the engine components can assist in diagnosing fuel delivery problems. Likewise, knowing where the electrical system connects can prevent unnecessary disassembly during a repair.

Benefits of a Clear Component Map

A well-structured visual guide makes it easier to pinpoint areas that may need attention. Whether you’re replacing a worn-out part or performing a detailed inspection, having a clear reference can save time and effort. Minimizing mistakes is crucial, and a detailed breakdown helps avoid unnecessary disassembly and potential damage to undamaged components. Moreover, having this reference readily available during maintenance ensures that each task is approached systematically.

How to Identify Key Tractor Components

Understanding how to locate and recognize essential elements of a farm vehicle is critical for efficient operation and maintenance. By familiarizing yourself with the layout of the machinery, you can identify which sections require attention or repair. Knowing where each component is situated and how it contributes to the overall performance ensures smoother troubleshooting and faster fixes.

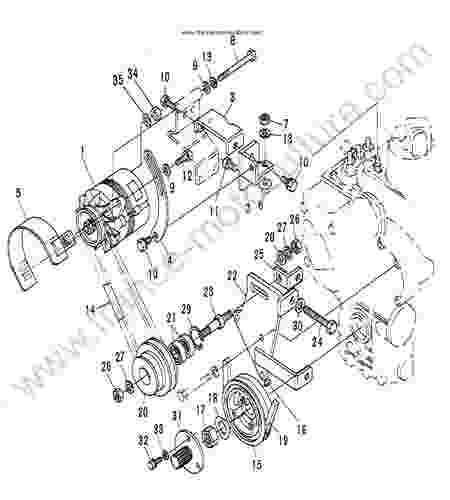

Engine and Transmission Systems

The engine is the heart of any machine, and knowing its key parts is the first step in identifying issues. Pay attention to the fuel lines, air intake, and cooling systems. Similarly, the transmission system, responsible for transferring power from the engine to the wheels, contains several critical components such as gears and belts. Understanding their placement can help detect any mechanical failures early.

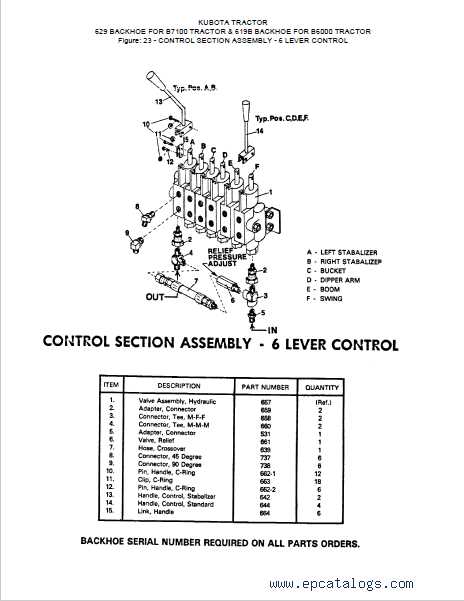

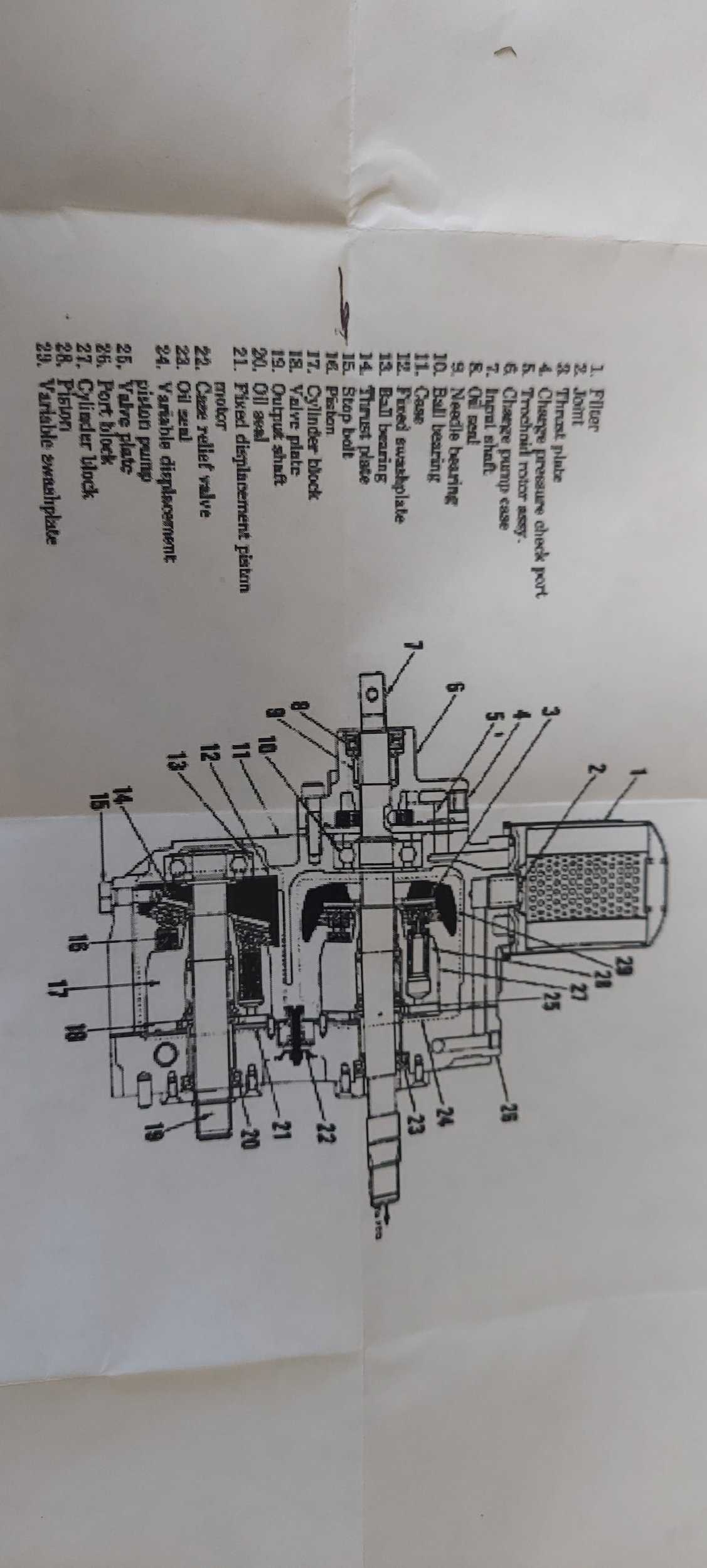

Hydraulic and Electrical Systems

Hydraulic systems, used for powering various implements and attachments, rely on fluid flow and pressure to function correctly. Identifying the hydraulic pump, hoses, and valves can prevent unnecessary disassembly during repairs. Additionally, the electrical system, including the battery, wiring, and alternator, is essential for starting the machine and powering accessories. A clear understanding of these components allows for more effective diagnosis of electrical issues.

Common Issues and Parts Replacement Tips

When maintaining farm machinery, some issues are more common than others, and being able to identify them quickly can save time and reduce repair costs. Knowing what parts are most likely to wear out or malfunction allows for better preparedness and more effective troubleshooting. This section provides insight into frequent problems and practical advice for replacing key components.

Engine and Cooling System Problems

Overheating is a frequent issue caused by a malfunctioning cooling system. The radiator, hoses, or thermostat may be clogged or damaged, leading to inefficient cooling. Regularly inspect these components to prevent overheating and potential engine failure. If the cooling system is compromised, replacing damaged hoses or cleaning the radiator can restore optimal performance.

Electrical System Failures

Electrical issues, such as dead batteries or faulty wiring, are also common. If your machine is not starting or exhibits intermittent electrical problems, check the battery connections and wiring for corrosion or loose connections. Replacing a worn-out battery or repairing damaged wiring can quickly resolve many electrical failures.