Water softeners are essential for maintaining the quality of water in your home, ensuring it is free from hard minerals that can damage pipes and appliances. Knowing the key elements that make up the system can help you identify issues early and ensure proper maintenance. Understanding how each component works together can simplify repairs and replacement tasks when necessary.

Having a clear view of the various parts involved in the softening process allows homeowners to handle troubleshooting effectively. In this guide, we will break down the different components, how to identify them, and provide valuable insights on keeping the system running smoothly for years. Whether you are looking to repair or replace a part, this knowledge will help you make informed decisions.

By learning about the components, you’ll gain confidence in managing your water treatment system. This will save time and money by preventing unnecessary service calls and ensuring your system remains efficient. Familiarizing yourself with the system’s key elements is a valuable step in taking control of its performance.

Understanding the Water Softener System Components

Proper knowledge of your water treatment system’s internal structure is crucial for efficient maintenance and troubleshooting. Recognizing how the various elements interact will help you identify issues before they escalate and simplify the repair process. Familiarity with the layout of key components is the first step in mastering your system’s functionality.

Key Elements of the System

Each water softener consists of several essential components that work together to ensure effective operation. Some of the most important include:

- Control Valve: Directs the flow of water through the system and manages regeneration cycles.

- Resin Tank: Houses the resin beads that remove calcium and magnesium from the water.

- Brine Tank: Holds the salt solution used to regenerate the resin beads.

- Distributor Tube: Ensures water is evenly distributed throughout the resin bed.

- Bypass Valve: Allows you to disconnect the softener when needed without shutting off the entire water supply.

Why Understanding the Layout is Important

Knowing the specific function of each component helps when diagnosing problems, whether it’s a reduced flow rate or a lack of softening. Recognizing where each element is located and how it contributes to the overall system ensures more precise troubleshooting and quicker fixes. Understanding the layout also makes the process of replacing faulty parts much more straightforward.

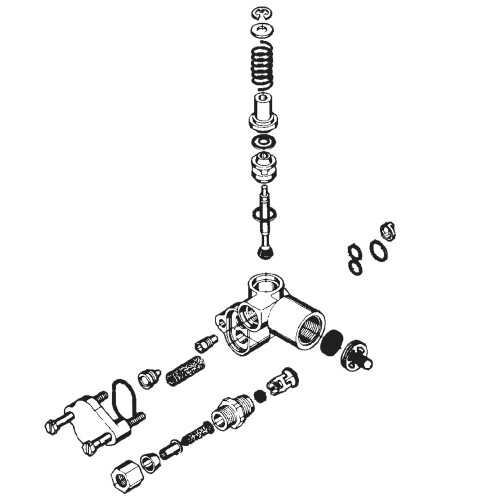

How to Identify Water Softener Components

Knowing how to identify the individual components within your water treatment system is essential for proper maintenance and repairs. Recognizing each part allows you to address any issues that may arise and determine whether repairs or replacements are needed. Being able to quickly locate and assess the key elements ensures that your system runs efficiently over time.

Start by familiarizing yourself with the main housing, valves, and tanks that make up the system. These components can typically be identified by their distinct shapes, sizes, and materials. Each part has a specific function, and understanding its role within the system will help you when performing routine checks or when an issue arises.

Most systems will also have clear labeling or part numbers to help in identification. Checking these labels and cross-referencing with the user manual or online resources can further simplify the identification process. If in doubt, take note of the component’s location within the system to make sure you are looking at the correct part during maintenance or troubleshooting.

Common Issues and Replacement Parts

Like any mechanical system, water treatment systems can experience issues over time. Understanding common malfunctions and knowing how to replace the faulty components is essential for maintaining system efficiency. In many cases, regular maintenance and timely part replacement can extend the life of the system and ensure its proper operation.

Common Problems in Water Softeners

Several issues may arise in your system, often due to wear and tear or clogging. Some of the most frequently encountered problems include:

- Reduced Water Flow: This can be caused by blockages in the control valve or resin tank, leading to inefficient filtration.

- Salt Bridges: A salt bridge occurs when a solid crust forms in the brine tank, preventing proper regeneration.

- Leaking Valves: If seals or O-rings become worn out, they can cause water to leak from the control valve.

- System Not Regenerating: A malfunctioning timer or control valve can cause the regeneration process to fail, leaving the resin bed ineffective.

Replacing Faulty Components

When problems occur, identifying the faulty part and replacing it promptly can restore your system to full functionality. Common replacement items include:

- Control Valve: The valve may wear out and require replacement to maintain proper water flow.

- Resin Beads: Over time, the resin beads in the tank lose their ability to remove minerals, necessitating a replacement.

- Brine Tank Parts: Components such as the float valve and brine line may need to be replaced if they become damaged or clogged.

Before replacing any part, make sure to check the manufacturer’s guidelines and ensure compatibility with your system. By addressing issues early and replacing worn-out components, you can keep your water softener operating at its best for longer periods.