Maintaining a lawn mower in optimal condition requires a clear understanding of its internal components. Whether you’re a seasoned mechanic or a casual user, having the right visual aids can simplify the repair and replacement process. Knowing where each piece fits and functions helps in identifying potential issues before they become serious problems.

By breaking down the system of a lawn mower, it becomes easier to locate the exact area of concern. With a clear reference, you can identify parts that need regular maintenance or replacement, preventing unnecessary downtime. This guide will help you navigate through these components with ease, ensuring the longevity and efficiency of your machine.

Comprehending the layout of your equipment and its parts is crucial for proper upkeep. A detailed map of the system is an invaluable tool for both routine checks and more in-depth repairs. Whether you’re troubleshooting or just performing standard maintenance, knowing the names and functions of key components is the first step in keeping your mower running like new.

Understanding the John Deere X590 Parts

Every machine is made up of numerous components that work in harmony to ensure smooth operation. Whether you’re looking to troubleshoot a malfunction or perform routine maintenance, having a clear understanding of each individual element is essential. A comprehensive guide to the parts will give you the knowledge needed to keep the equipment functioning properly for years to come.

Key Components and Their Functions

At the heart of any mower are essential parts such as the engine, transmission, and deck assembly. Each of these elements plays a pivotal role in the overall performance. The engine is responsible for powering the machine, while the transmission ensures smooth movement across the lawn. The deck assembly holds the blades, allowing the mower to cut grass efficiently. Knowing where each piece is located and how it operates makes maintenance much simpler.

Maintenance and Replacement Considerations

Over time, even the most durable parts may experience wear and tear. Regular inspection is crucial to detect any signs of damage before they lead to more significant issues. Commonly replaced elements include belts, filters, and blades. By understanding their functions and identifying them quickly, you can ensure that each part is replaced or serviced as needed, keeping your machine in optimal working condition.

How to Use the X590 Parts Diagram

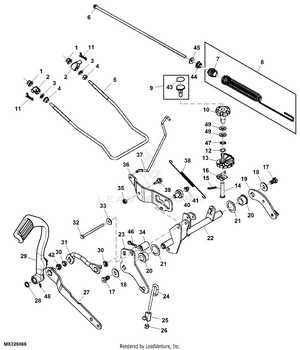

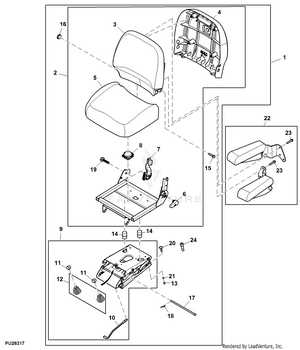

Having a visual reference for your equipment’s components is essential when it comes to maintenance or repair. A detailed map of the internal structure provides clarity on where each piece fits and how they interact with each other. By using such a guide, you can quickly locate any malfunctioning or worn-out parts, making the repair process much more efficient.

To make the most of this visual tool, start by familiarizing yourself with the layout. The diagram typically groups parts into different sections based on their function, such as the engine, transmission, or cutting deck. By following the numbered references, you can identify specific parts that need attention, whether it’s for troubleshooting or regular maintenance.

Additionally, these guides often include part numbers, making it easier to order replacements. If you need to perform a specific repair, the visual reference will ensure you’re working with the correct components, saving time and reducing the chances of errors. Understanding how to navigate this tool will not only make your repairs more precise but also help you stay on top of the necessary upkeep for your machine.

Common Issues and Replacement Parts for X590

Over time, machinery will inevitably experience wear and tear, leading to common issues that need attention. Knowing what to look for can save you time and prevent more serious damage. Identifying these problems early allows you to replace or repair the affected components, ensuring continued performance and reliability.

One of the most frequent problems is with the cutting mechanism. Blades can become dull, bent, or damaged after extended use. It’s important to check the condition of the blades regularly and replace them if necessary. Additionally, issues with the belts can lead to poor functioning or even total failure. These belts, responsible for transmitting power to various parts of the machine, should be inspected for signs of wear, fraying, or breakage.

Another area to monitor is the engine filter and fuel lines. A clogged air or fuel filter can lead to inefficient operation or engine stalling. Replacing these filters regularly ensures the engine runs smoothly. Similarly, damaged or cracked fuel lines can cause leaks, which may lead to safety hazards. Replacing the fuel lines promptly will prevent fuel loss and maintain optimal engine performance.