For anyone working with heavy-duty machinery, having a clear understanding of its individual elements is essential. Knowing how each part fits together can make maintenance and repairs more efficient, allowing for longer-lasting performance. By breaking down the assembly, you gain insight into the functionality of your tool, enabling smoother operations in various conditions.

Proper knowledge of a chainsaw’s structure is invaluable, whether you’re performing routine inspections or troubleshooting issues. With the right guide, it’s possible to identify worn-out or damaged components quickly, reducing downtime and preventing potential breakdowns.

Visual guides serve as a practical tool for any user aiming to deepen their mechanical understanding. These references highlight the placement and connections between the various parts, providing clarity on how everything works in harmony. Such resources are indispensable for anyone looking to keep their equipment in top condition.

Understanding Chainsaw Assembly Layout

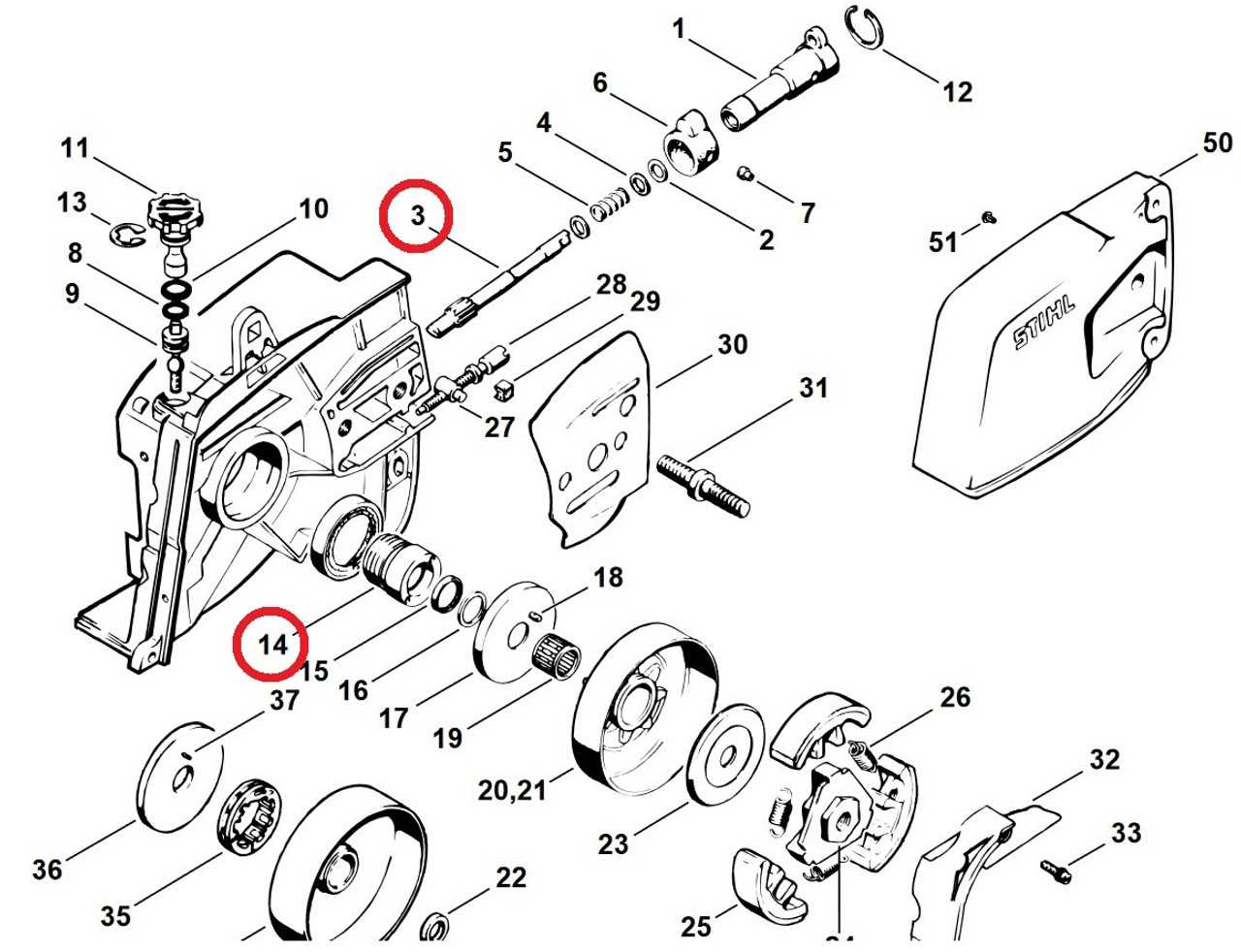

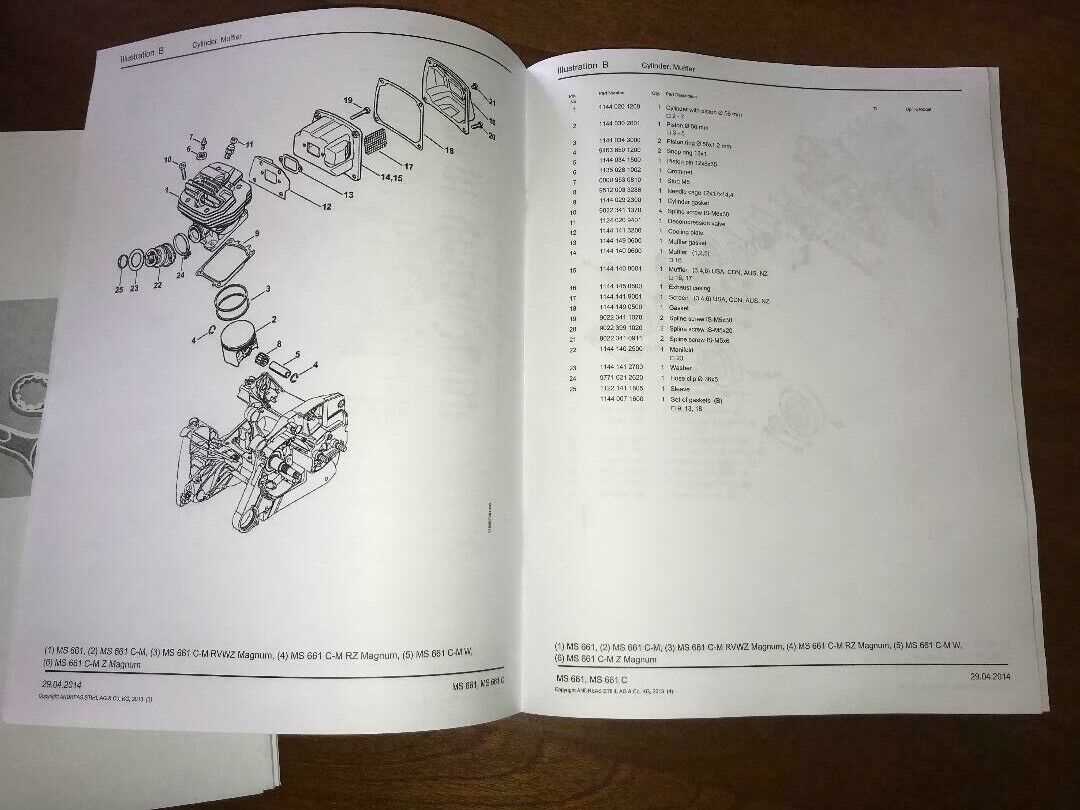

When working with complex machinery, having a clear overview of its structure is crucial for effective maintenance and repair. A visual guide to the internal components helps users identify the arrangement and connection of each piece, ensuring efficient functioning. Understanding how the various elements work together provides a foundation for troubleshooting and part replacement.

Key Features and Component Locations

Each section of the tool plays a vital role in its overall performance. By familiarizing yourself with the arrangement of key elements like the engine, drive mechanism, and safety features, you can quickly assess the condition of your equipment. This knowledge is essential for performing repairs, as it helps you locate specific components that may need attention.

Common Wear and Tear Areas

Knowing where wear and tear typically occur can save time and effort during inspections. High-stress areas like the drive system, cooling mechanisms, and external covers are more likely to show signs of damage. By regularly checking these sections, you can address issues early, extending the lifespan of your machine and avoiding costly repairs.

Key Components of a Professional Chainsaw

Every machine is built from essential components that work together to achieve its purpose. In the case of a chainsaw, understanding the role of each major element is crucial for optimal performance. From the power system to the cutting mechanism, each part contributes to the overall efficiency and safety of the tool. Familiarity with these components allows for better maintenance, quicker repairs, and informed upgrades.

Engine and Power System

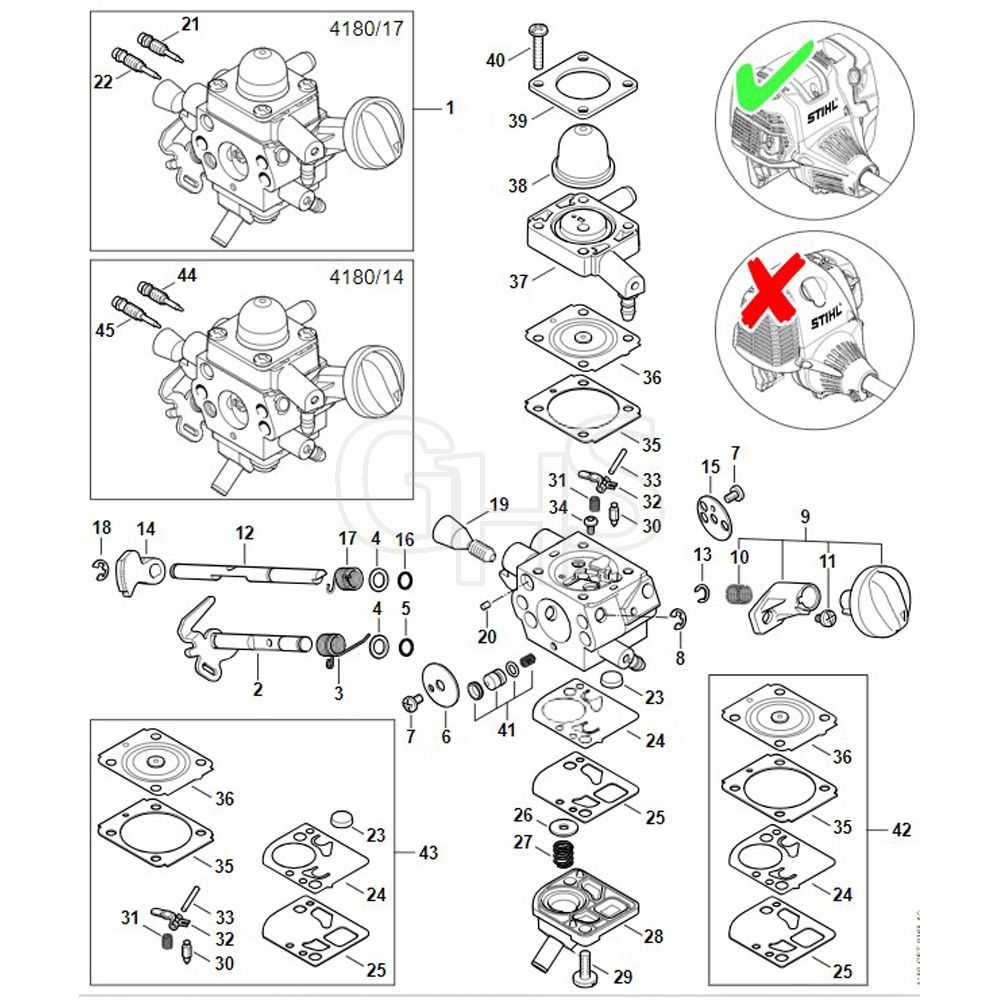

The engine serves as the heart of the chainsaw, converting fuel into mechanical energy to drive the cutting chain. This system includes the carburetor, spark plug, and fuel tank, which together regulate the fuel flow and combustion process. Proper maintenance of the engine ensures smooth operation and reduces the likelihood of performance issues.

Cutting Mechanism and Guide Bar

The cutting mechanism is made up of the chain, guide bar, and sprocket. The chain moves along the guide bar, powered by the engine, to perform the cutting action. Regular inspection of the chain’s sharpness and the guide bar’s alignment is essential to prevent inefficient cutting and unnecessary wear. This system is designed for durability, but it requires routine checks to maintain top-level performance.

How to Interpret the Parts Layout

Understanding a visual representation of a tool’s assembly is essential for efficient maintenance and repair. These guides provide a clear view of the tool’s components, showing how each element fits together and interacts. By learning to read and interpret these layouts, you can quickly locate specific parts, diagnose issues, and streamline the repair process.

Each section of the diagram typically represents a specific part of the machine, marked with identification numbers or labels. These identifiers correspond to individual components, allowing you to match them with the correct replacements or adjustments. By focusing on these details, you gain insight into the tool’s structure and functionality, making it easier to perform necessary maintenance.