For those who own and operate agricultural machinery, understanding the various components is essential for efficient performance and long-lasting durability. By becoming familiar with the internal structures and assembly of the machine, you can ensure proper care and quick identification of any issues that may arise.

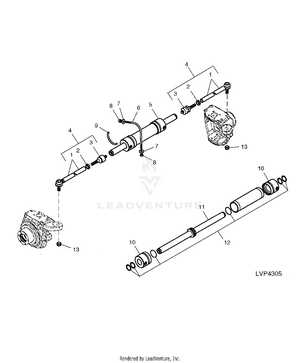

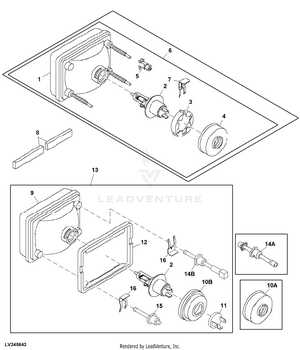

A well-detailed visual representation of the equipment’s assembly can be an invaluable resource, helping owners perform repairs and replacements with confidence. These references provide clarity on where each part fits and how it interacts with other elements, streamlining maintenance processes and minimizing downtime.

Whether you’re looking to replace a worn-out part or perform routine maintenance, having a clear understanding of the machinery’s structure will make tasks easier and more accurate. This guide is designed to help you navigate through your equipment’s setup and keep it running smoothly for years to come.

Understanding John Deere 5105 Components

Properly maintaining heavy machinery requires a solid understanding of its individual components and how they function together. Each element of a tractor, from the engine to the smallest bolt, plays a crucial role in ensuring optimal performance. Familiarizing yourself with these elements is key to effective troubleshooting and maintenance.

Each section of the machine is designed for specific tasks, whether it’s for power transmission, steering, or fuel management. By recognizing the purpose of every major and minor part, you can more easily spot signs of wear or malfunction. This knowledge will guide you through the maintenance process, helping you make informed decisions about repairs and replacements.

Engine components are perhaps the most vital for overall operation, while hydraulic systems contribute to lifting and handling tasks. Similarly, transmission elements ensure the machine moves with the necessary speed and torque for various field operations. Each group of parts requires distinct care, but understanding how they interact enhances overall machine longevity.

How to Use the Parts Diagram Effectively

Utilizing a detailed visual representation of your machinery can significantly improve the efficiency of maintenance and repairs. A comprehensive illustration helps you identify specific components and understand their placement within the overall structure. Knowing how to read and navigate these resources will save time and reduce errors during repairs.

Step-by-Step Approach

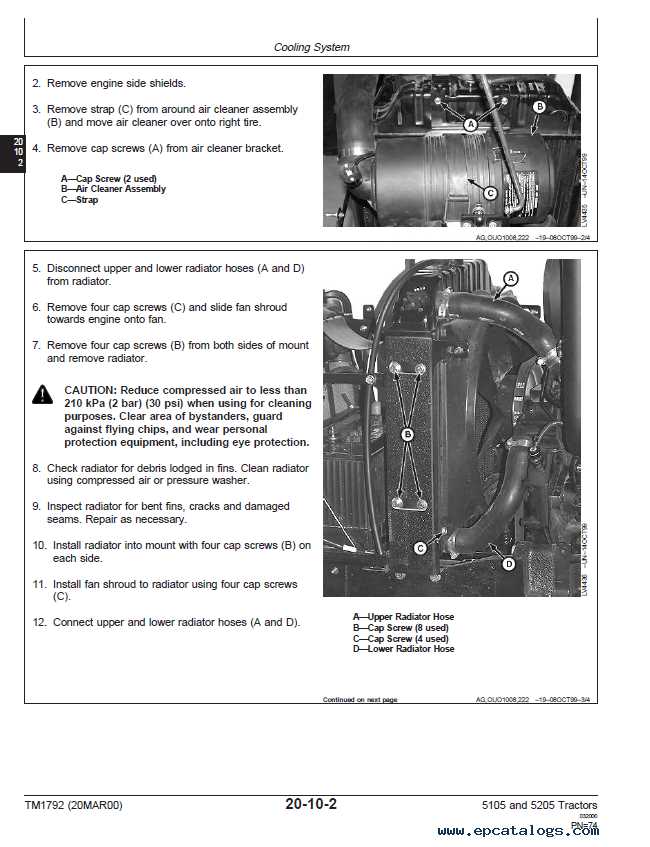

- Start by identifying the section you need to work on, whether it’s the engine, transmission, or hydraulic system.

- Look for labels or numbers next to each part. These often correspond to a list of specific components, making it easier to find what you need.

- Cross-reference with the equipment manual to ensure you have the correct part numbers for replacements or repairs.

- Pay attention to the orientation of each part, as some components are designed to fit only one way.

Key Tips for Efficient Use

- Highlight or mark sections of the diagram relevant to your task to avoid unnecessary confusion.

- Consult the diagram regularly during assembly or disassembly to stay on track.

- Familiarize yourself with common error zones, where parts are most likely to wear or break.

With these strategies, you can maximize the value of the visual guides and carry out maintenance with greater accuracy and confidence.

Common Repairs for John Deere 5105

As with any heavy-duty machinery, regular use often leads to wear and tear on various components. Recognizing common issues early on can help you avoid costly repairs and downtime. From engine troubles to minor part failures, understanding the most frequent problems will prepare you to act quickly and effectively.

One of the most common areas of concern is the fuel system. Over time, fuel injectors and filters may clog, reducing engine efficiency. Cleaning or replacing these components is crucial for smooth operation. Another frequent issue is with the hydraulic system. Leaks or pressure loss can compromise lifting capabilities and require prompt attention to prevent further damage.

Transmission problems are also a common repair area, particularly in cases where shifting becomes difficult or the machine is unable to maintain the proper speed. Addressing worn-out gears or seals early can help extend the life of the transmission and avoid more severe complications down the road.