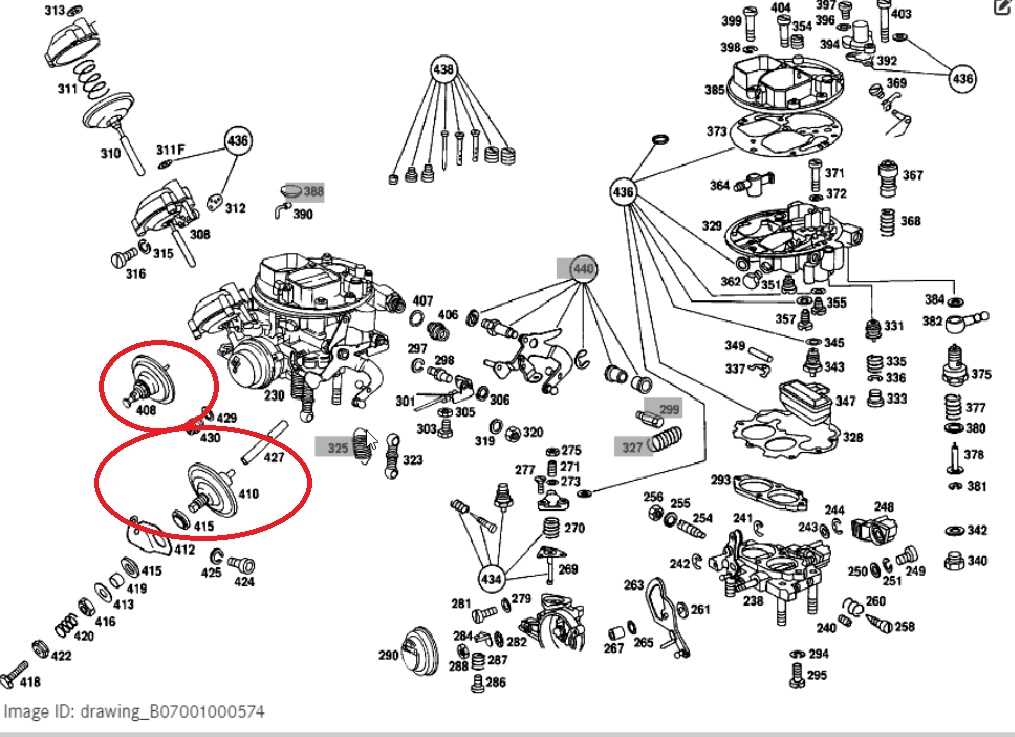

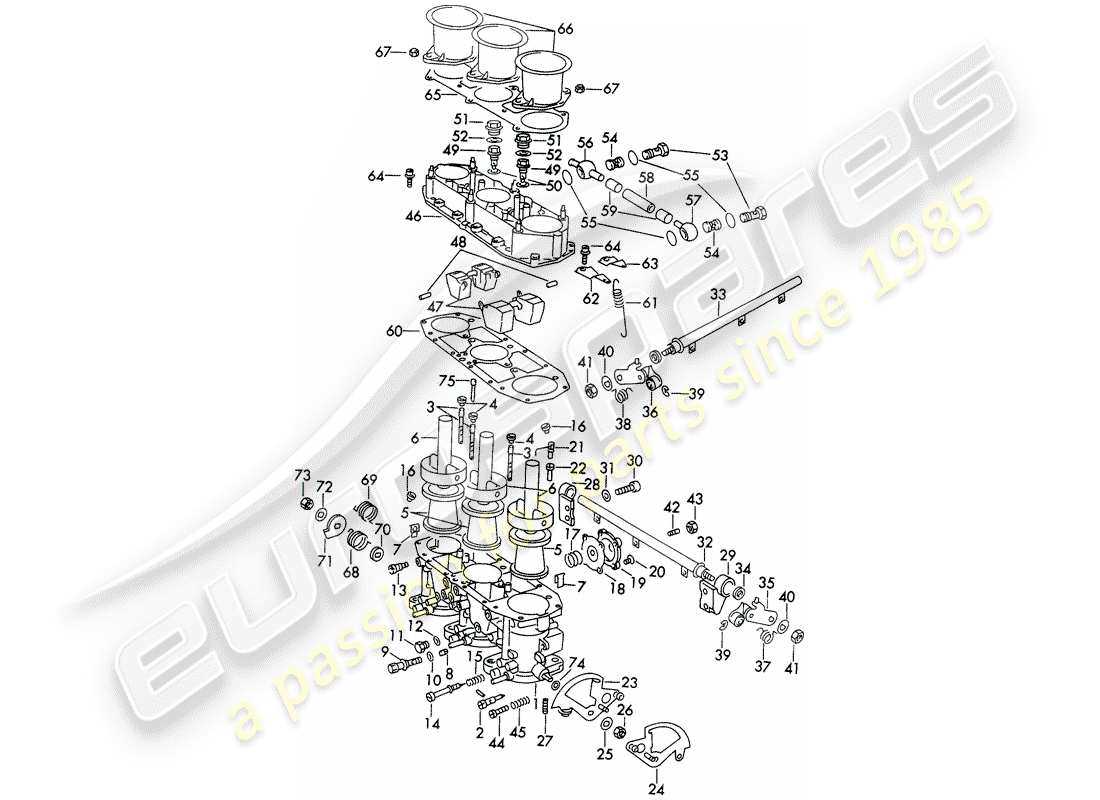

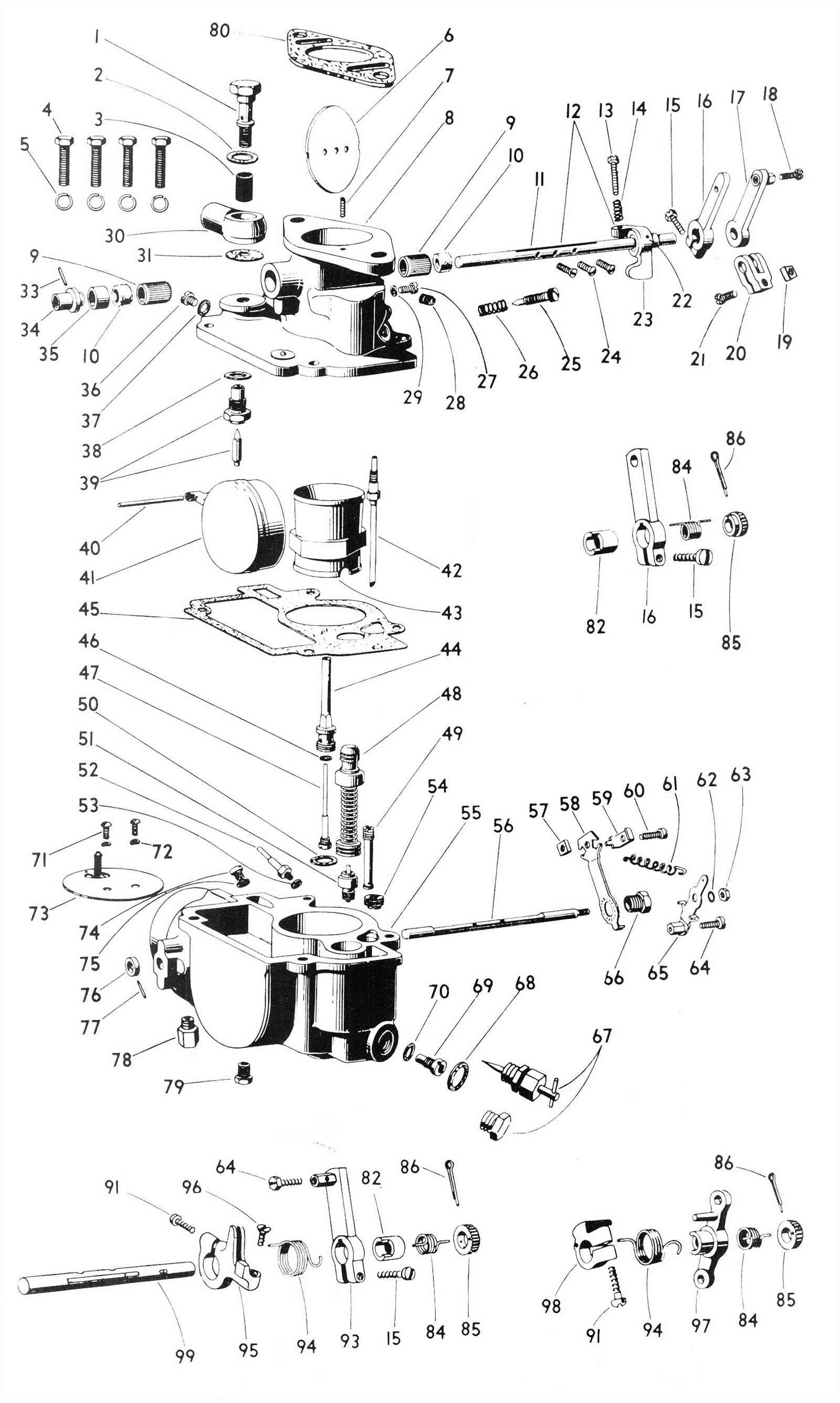

When maintaining or repairing an engine, it’s essential to understand the arrangement of its internal mechanisms. Visual guides that outline the structure of these systems help identify each element and its function. This knowledge allows for more efficient diagnostics and repairs, ensuring the longevity and performance of the engine.

For engine enthusiasts and mechanics alike, referring to clear visual references is a key part of the process. These detailed schematics break down the assembly into manageable sections, making complex systems easier to understand. By examining these guides, one can gain valuable insight into the connections and roles of each component, simplifying troubleshooting and upgrades.

Whether you’re a professional or a hobbyist, being familiar with these layouts is an essential skill. Recognizing the different parts and their positions provides a strong foundation for effective engine maintenance and repair.

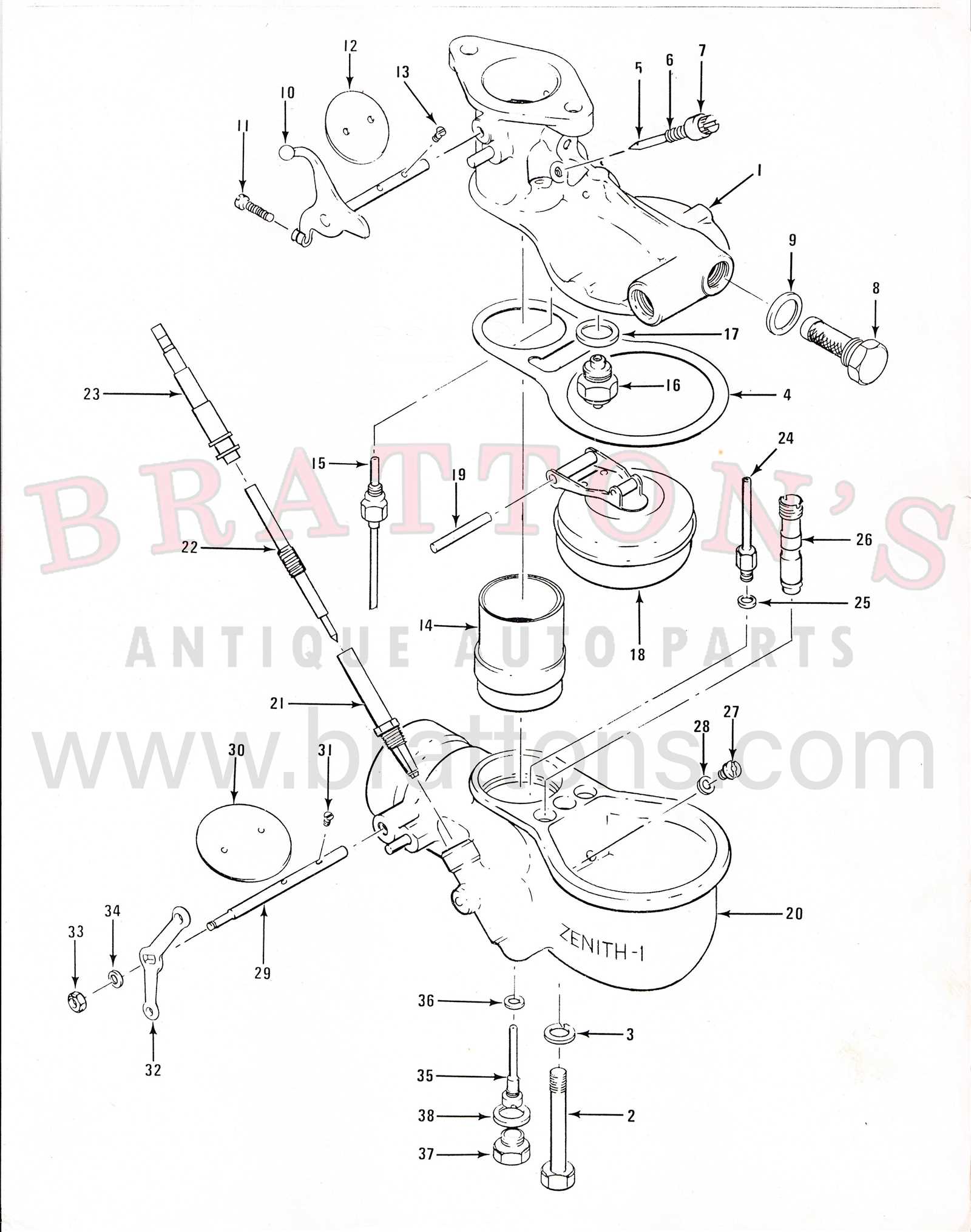

Understanding Zenith Carburetor Components

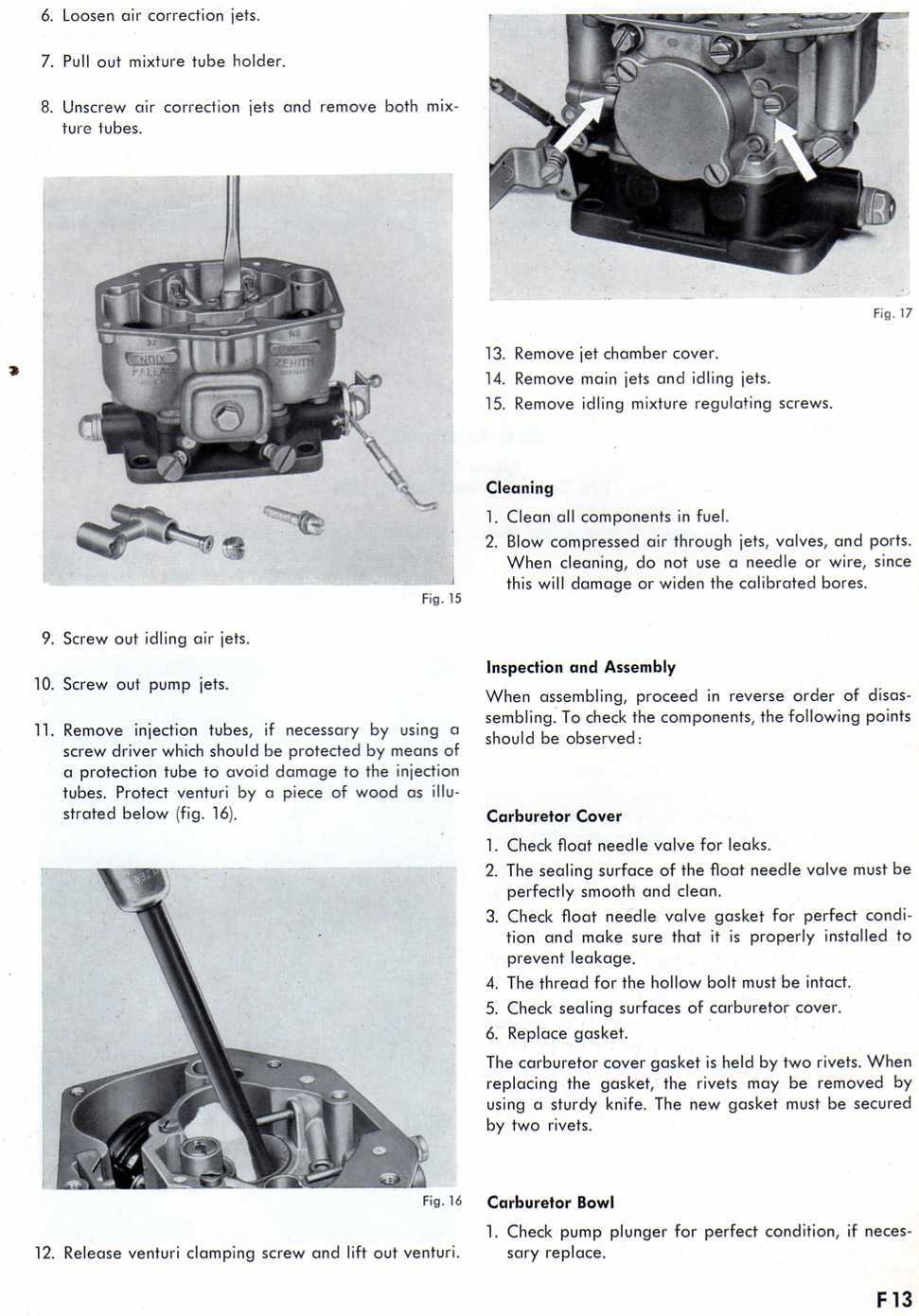

When dealing with engine fuel delivery systems, it’s crucial to understand the various components that regulate airflow and fuel mixing. Each element has a specific function that contributes to optimal engine performance. Understanding how these components work together allows for more efficient troubleshooting and maintenance.

The main components responsible for air-fuel regulation are critical to engine efficiency. These include the throttle body, fuel metering systems, and air intake mechanisms. By studying the layout and function of each piece, mechanics can identify potential issues that affect overall engine performance.

In addition, a clear understanding of the flow paths and the interaction between the components enables better decision-making when it comes to repairs or replacements. Being familiar with these internal systems ensures that the engine runs smoothly, providing consistent power and reliability.

How to Read a Carburetor Parts Diagram

Understanding how to interpret visual guides of engine fuel systems is essential for anyone performing maintenance or repairs. These illustrations break down the entire assembly into labeled components, making it easier to identify each piece and understand its function. Knowing how to read and use these schematics helps streamline the repair process and ensures proper reassembly.

Identifying Key Components

The first step in reading these guides is recognizing the key components. Look for labels or numbers associated with each part to learn its specific role within the system. Pay attention to the layout, as it shows how each element connects to others and interacts within the system. Thorough knowledge of these parts helps prevent confusion during repairs.

Interpreting Flow and Function

Another critical aspect is understanding the flow of air and fuel through the system. These guides typically include arrows or lines that illustrate the path each substance takes. By studying these visual cues, you can easily trace the route and identify any potential blockages or inefficiencies that could affect engine performance.

Common Issues with Zenith Carburetors

Fuel delivery systems are prone to a variety of issues that can affect engine performance. Understanding the most common problems can help you identify and address them quickly. These issues often stem from worn-out components, improper adjustments, or blockages, which can lead to engine inefficiency, poor fuel economy, or starting difficulties.

One of the most frequent problems is improper fuel mixture. If the mixture is too rich or too lean, it can result in poor engine performance, including rough idling or stalling. This issue is typically caused by malfunctions in the fuel metering system or air intake valves. Regular inspection of these components can prevent such problems.

Another common issue is clogged fuel lines or jets, which restrict the flow of fuel. Over time, dirt and debris can accumulate in these narrow passages, leading to poor fuel flow and inconsistent engine power. Cleaning or replacing the affected components is usually the best solution to restore proper function.